Custom Barite Powder for Drilling - High-Quality Drilling Fluid Solutions

Exploring Custom Barite Powder for Drilling Factories

Barite, or barium sulfate (BaSO4), is a crucial mineral widely used in various industries, particularly in drilling operations for oil and gas. Its unique properties, including high density, chemically inert nature, and low solubility, make it an ideal choice for drilling fluids, also known as muds. In recent years, there has been a growing demand for custom barite powder tailored to the specific needs of drilling factories. This article delves into the significance of custom barite powder and its advantages in the drilling industry.

One of the primary reasons for opting for custom barite powder is the specific requirements of various drilling operations. Different wells present unique challenges, such as varying depth, pressure, and geological formations. Standard barite may not meet the precise characteristics required for optimal performance in these unique environments. By sourcing custom barite powder, drilling companies can obtain materials that are specifically designed to meet their operational needs. This tailored approach helps enhance drilling efficiency and minimize potential complications during the drilling process.

Another advantage of utilizing custom barite powder is the ability to adjust particle size and distribution. The performance of drilling fluids significantly depends on the size and distribution of the solids contained within them. For instance, finer barite powder can facilitate better suspension properties and improve the overall stability of drilling mud, while coarser particles can contribute to weight and density. By customizing the particle size, drilling factories can optimize their mud systems for enhanced fluid control and wellbore stability.

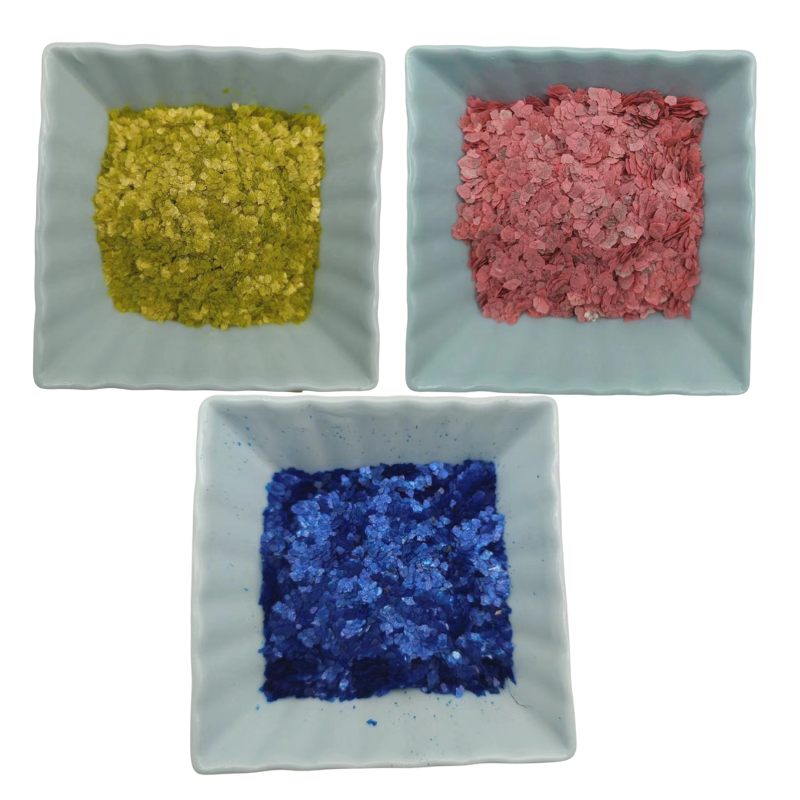

custom barite powder for drilling factories

Additionally, custom barite can be engineered to attain various additional properties. For example, certain formulations may include additives that enhance the fluid’s viscosity, reduce fluid loss, or improve thermal stability. These enhancements can be particularly beneficial in challenging drilling environments, such as deepwater or high-temperature applications, where the performance of standard barite may fall short.

The sourcing of custom barite powder also reflects the growing trend of sustainable practices in the drilling industry. Companies are increasingly seeking environmentally friendly solutions, and custom barite suppliers are responding by offering products that reduce the environmental footprint. By considering the entire lifecycle of materials, from extraction to disposal, these suppliers can help drilling companies maintain compliance with environmental regulations while ensuring top performance.

Furthermore, the logistics of obtaining custom barite powder are becoming more streamlined, thanks to advancements in supply chain management and distribution networks. This development allows drilling factories to secure their customized products promptly, minimizing downtime and optimizing operational efficiency. Collaborative relationships with suppliers can lead to innovations and improvements in product formulation and application methods, providing a competitive edge in the market.

In conclusion, the demand for custom barite powder in drilling factories highlights the dynamic nature of the industry and the need for specialized materials to meet specific operational challenges. By customizing barite powder, drilling companies can enhance their efficiency, improve performance, and adhere to environmental standards. As the industry evolves, the importance of tailored solutions will continue to grow, making custom barite powder a vital component in the success of drilling operations.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025