Exploring the Impact of Clay Pebbles on Floating Factory Efficiency and Sustainability

The Floating Factories of Clay Pebbles A Sustainable Innovation

In recent years, the concept of floating factories has gained traction as industries explore new ways to mitigate environmental impacts while enhancing production efficiency. Among these innovative structures, clay pebble floating factories represent a fascinating intersection of technology, sustainability, and aquatic engineering. These factories not only sport unique designs but also offer various ecological advantages that could revolutionize traditional manufacturing processes.

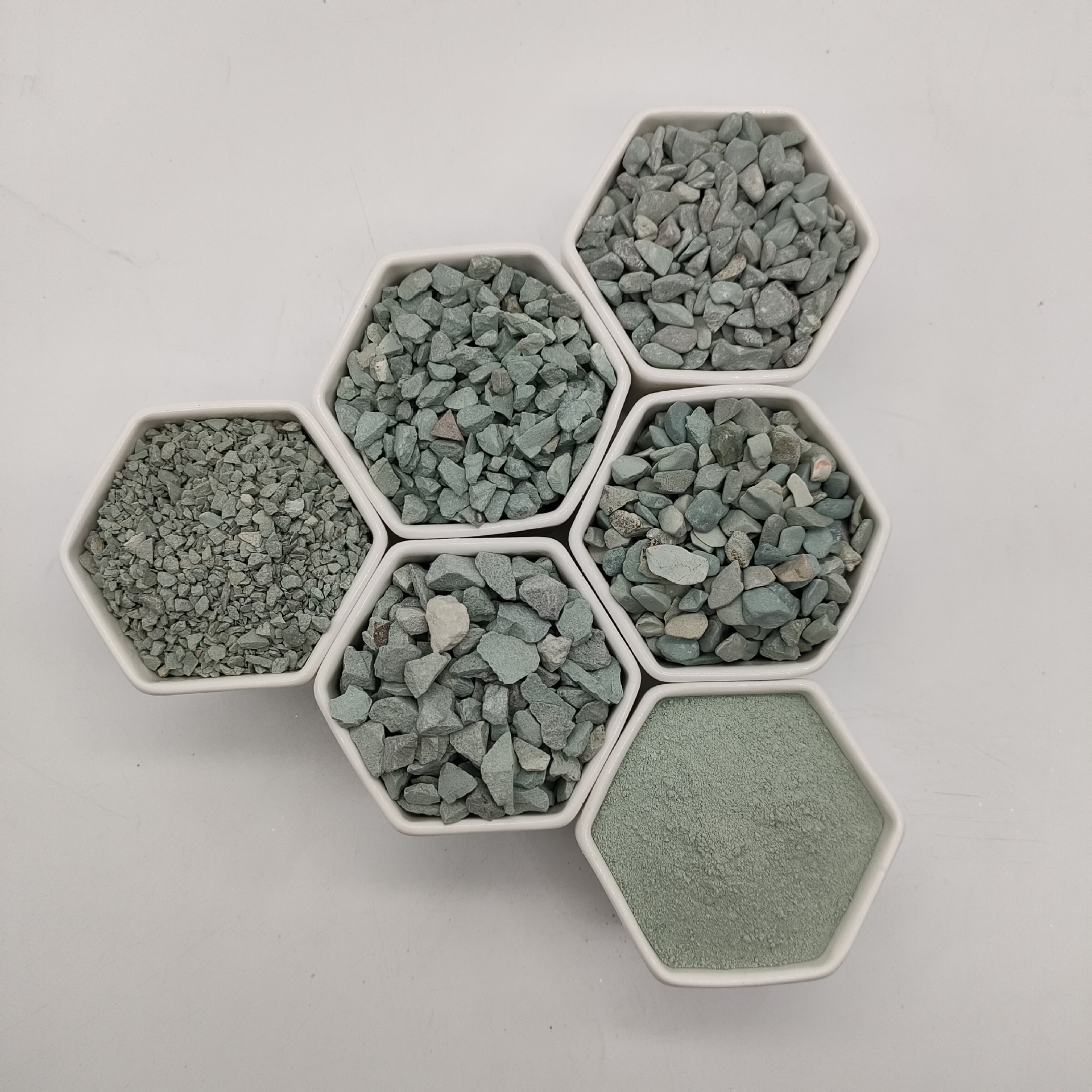

What Are Clay Pebbles?

Before delving into floating factories, it's essential to understand what clay pebbles are. Clay pebbles, often used in gardening and hydroponics, are lightweight, porous balls made from expanded clay. They have several properties, including excellent drainage, aeration, and insulation, making them ideal for various applications beyond mere horticultural usage. When we envision these pebbles used in floating factories, we consider their buoyant and structural potential.

The Concept of Floating Factories

Floating factories are essentially manufacturing units that operate on water, harnessing the abundant marine resources while minimizing land use. This innovation takes advantage of available space on oceans, rivers, and lakes, wherein traditional manufacturing is often constrained by geographical and environmental restrictions. These floating structures incorporate advanced modular designs that can be tailored to various industrial needs, whether for food production, textiles, or even electronics.

Environmental Benefits

1. Minimized Land Use One of the most significant advantages of clay pebble floating factories is their minimal land footprint. By utilizing waterways, these factories can accommodate growing industries without encroaching on vital terrestrial ecosystems. This is particularly important in urban areas where land is scarce and expensive.

clay pebbles floating factories

2. Water Efficiency Traditional manufacturing processes consume substantial amounts of freshwater. In contrast, floating factories can exploit nearby water sources for non-potable applications, such as cooling and processing, thus significantly reducing freshwater consumption. The integration of advanced filtration and recycling systems can further enhance water sustainability in these facilities.

3. Reduced Waste Clay pebbles can play a pivotal role in implementing closed-loop systems within floating factories. Their reuse and recycling potential can minimize waste production, thereby promoting a circular economy model. Industries can repurpose clay pebbles and other materials, maximizing resource efficiency.

4. Energy Efficiency Floating factories can utilize renewable energy sources such as solar and wind power more effectively than traditional factories. Their placement on water bodies allows for optimal exposure to sunlit surfaces, while wind harnessing technology can efficiently capture wind energy. This dual energy approach not only reduces dependence on fossil fuels but also lowers overall carbon emissions.

Economic Opportunities

The rise of clay pebble floating factories also presents various economic opportunities. These facilities can facilitate new markets in coastal and developing regions. By creating jobs and stimulating local economies, they can contribute to social upliftment. Moreover, the innovative nature of these factories could attract investment in research and development, further driving technological advancements.

Challenges and Future Prospects

While clay pebble floating factories promise numerous benefits, they also face challenges. Issues such as regulatory frameworks, marine environment protection, and technological feasibility must be addressed to fully realize this concept. The structural integrity of floating platforms and their resilience to natural elements are critical factors to consider in their design and execution.

In conclusion, clay pebble floating factories represent a forward-thinking approach to modern manufacturing that aligns with sustainable practices. They not only provide a solution to land constraints but also promote water efficiency, reduce waste, and harness renewable energy. As industries continue to battle the effects of climate change, integrating such innovative models may provide the necessary impetus for a more sustainable industrial future. The journey ahead is filled with potential, and with the right investments and collaborative efforts, clay pebble floating factories might just become a cornerstone of 21st-century manufacturing.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025