Feb . 11, 2025 20:40

Back to list

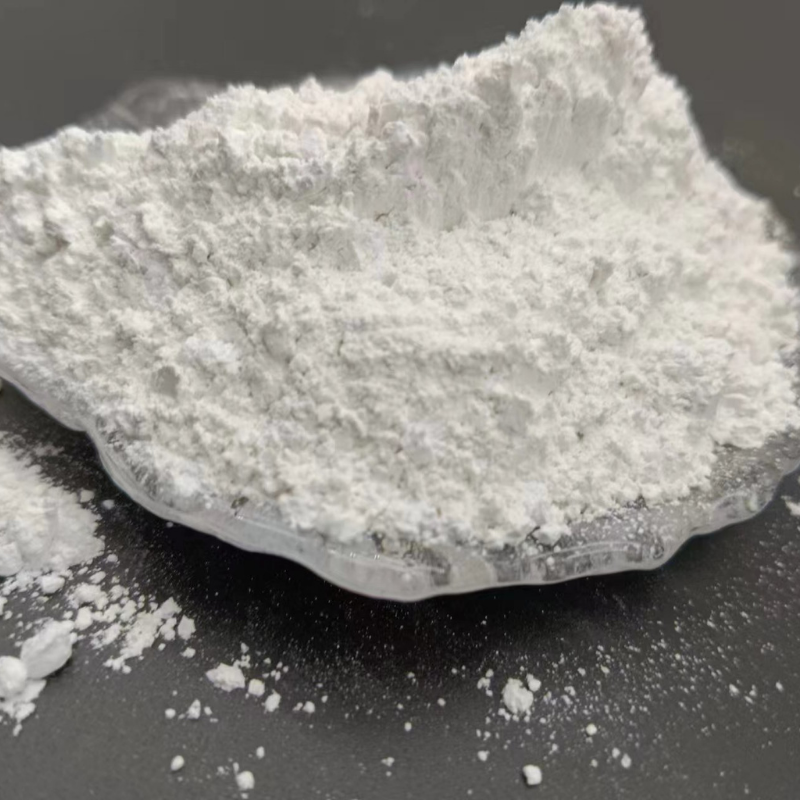

china titanium dioxide rutile factory

China has emerged as a global powerhouse in the production of titanium dioxide with an emphasis on rutile grade manufacturing. This transformation is driven by the increased demand for high-quality pigments across various industrial applications, from paints and coatings to plastics, papers, and cosmetics. In the heart of this development are innovative Chinese factories redefining efficiency, sustainability, and technological advancements in titanium dioxide production.

Trustworthiness is anchored in the transparent business practices and customer-oriented approach adopted by these factories. By fostering strong, long-lasting relationships with clients across the globe, Chinese manufacturers build trust through consistently meeting delivery schedules, upholding high-quality standards, and providing exceptional customer service. Additionally, many factories implement comprehensive quality control systems throughout the manufacturing process, ensuring that the final product meets precise specifications and client expectations. Chinese titanium dioxide rutile factories also significantly contribute to sustainability in the industry. Using innovative recycling processes and renewable energy sources, these manufacturers reduce their environmental footprint, aligning with the global shift towards greener industrial practices. They implement closed-loop production systems that recycle waste materials back into the manufacturing cycle, reducing waste and conserving resources. This commitment to sustainable manufacturing practices not only enhances the eco-friendliness of their operations but also appeals to increasingly environmentally-conscious consumers. These factories, scattered in key industrial regions like Jiangsu, Sichuan, and Chongqing, operate with a clear vision for the future of titanium dioxide production. By investing continually in research and development, they are set to propel the industry towards innovations in nanotechnology and new material composites, potentially opening new avenues for titanium dioxide applications. In summary, China's titanium dioxide rutile factories are setting global benchmarks through a potent mix of experience, expertise, authority, and trustworthiness. As these factories continue to harness advanced technologies and sustainable practices, they are expected to keep leading in the production of high-quality titanium dioxide, catering to diversified needs across various industrial sectors. With a solid foundation and a forward-thinking approach, they play a pivotal role in satisfying current demands while shaping the future of the industry.

Trustworthiness is anchored in the transparent business practices and customer-oriented approach adopted by these factories. By fostering strong, long-lasting relationships with clients across the globe, Chinese manufacturers build trust through consistently meeting delivery schedules, upholding high-quality standards, and providing exceptional customer service. Additionally, many factories implement comprehensive quality control systems throughout the manufacturing process, ensuring that the final product meets precise specifications and client expectations. Chinese titanium dioxide rutile factories also significantly contribute to sustainability in the industry. Using innovative recycling processes and renewable energy sources, these manufacturers reduce their environmental footprint, aligning with the global shift towards greener industrial practices. They implement closed-loop production systems that recycle waste materials back into the manufacturing cycle, reducing waste and conserving resources. This commitment to sustainable manufacturing practices not only enhances the eco-friendliness of their operations but also appeals to increasingly environmentally-conscious consumers. These factories, scattered in key industrial regions like Jiangsu, Sichuan, and Chongqing, operate with a clear vision for the future of titanium dioxide production. By investing continually in research and development, they are set to propel the industry towards innovations in nanotechnology and new material composites, potentially opening new avenues for titanium dioxide applications. In summary, China's titanium dioxide rutile factories are setting global benchmarks through a potent mix of experience, expertise, authority, and trustworthiness. As these factories continue to harness advanced technologies and sustainable practices, they are expected to keep leading in the production of high-quality titanium dioxide, catering to diversified needs across various industrial sectors. With a solid foundation and a forward-thinking approach, they play a pivotal role in satisfying current demands while shaping the future of the industry.

Share

Latest news

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025