china thermal insulation ceramsite manufacturer

Advancements in Thermal Insulation Ceramsite Production in China

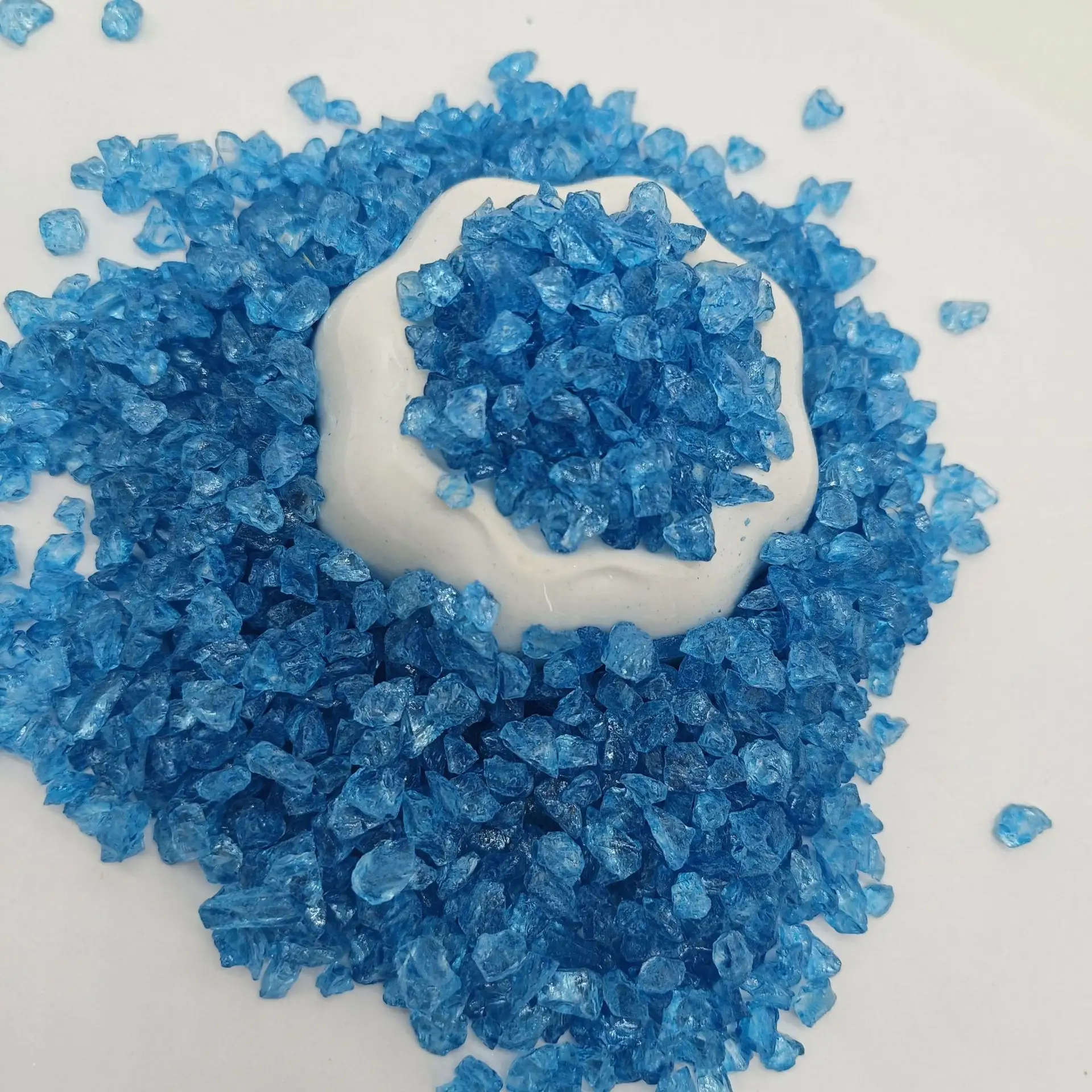

In recent years, China has emerged as a significant player in the global construction materials market, particularly with its production of thermal insulation materials like ceramsite. Ceramsite is a lightweight, aggregate material typically made from clay, shale, or other raw materials that undergo high-temperature firing. This process transforms the raw inputs into a porous, ceramic-like substance, making it ideal for thermal insulation applications.

The Importance of Thermal Insulation

Thermal insulation is a critical factor in modern construction, influencing energy efficiency, comfort, and overall sustainability. Effective insulation minimizes heat transfer between the interior and exterior of buildings, reducing the need for heating in winter and cooling in summer. By improving energy efficiency, thermal insulation not only lowers utility bills for homeowners and businesses but also plays a vital role in reducing carbon footprints and promoting environmental sustainability.

In this context, ceramsite stands out as one of the most effective thermal insulation materials available on the market. Its lightweight nature, combined with excellent thermal resistance, makes it an invaluable resource in building and industrial applications. As energy costs continue to rise and global climate initiatives gain traction, the demand for high-performance insulation materials like ceramsite is expected to grow significantly.

Manufacturing Processes in China

China has honed its manufacturing techniques for ceramsite, leading to substantial advancements in efficiency and output. The production process typically involves the following key steps

1. Raw Material Sourcing The primary materials for ceramsite production are clay, shale, and various other mineral compounds. China is rich in these resources, allowing manufacturers to secure high-quality raw materials affordably.

2. Preparation The raw materials are carefully processed, which involves crushing, grinding, and screening to achieve uniform particle sizes. This step is crucial since it directly affects the quality and performance of the final product.

china thermal insulation ceramsite manufacturer

3. Firing The processed materials are subjected to high temperatures in a kiln, causing them to expand and form porous structures. This step not only defines the thermal insulation properties of the ceramsite but also influences its mechanical strength.

4. Cooling and Quality Control After firing, ceramsite is cooled gradually. Rigorous quality control measures are taken to ensure consistency and performance standards, including testing for thermal conductivity, compressive strength, and density.

5. Packaging and Distribution Once the ceramsite has passed quality checks, it is packaged for distribution. With China's extensive logistics network, these materials can be efficiently transported to both domestic and international markets.

Market Trends and Future Prospects

The market for thermal insulation materials in China is expected to grow significantly, driven by increasing construction activities, particularly in urban areas. The government’s emphasis on energy-efficient building practices aligns with global sustainability goals, fostering a favorable environment for the ceramsite industry.

Moreover, advancements in material science are likely to lead to the development of even more efficient ceramsite formulations in the future. Innovations such as incorporating recycled materials or enhancing the fire-resistance properties of ceramsite could offer new opportunities in this sector.

The export potential of Chinese ceramsite is also notable. As countries worldwide embrace green building practices, the demand for high-quality insulation materials is expected to rise, and China, with its established manufacturing capabilities, is well-positioned to meet this need.

Conclusion

As one of the leading manufacturers of thermal insulation ceramsite, China is setting the stage for advancements in both product technology and manufacturing efficiency. With a commitment to sustainability and energy conservation, the future of ceramsite production in China looks promising. The ongoing development of innovative materials and processes will undoubtedly contribute to a more sustainable built environment both nationally and globally, highlighting the significant role of ceramsite in modern construction.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025