china sodium or calcium bentonite clay factories

An Overview of Sodium and Calcium Bentonite Clay Factories in China

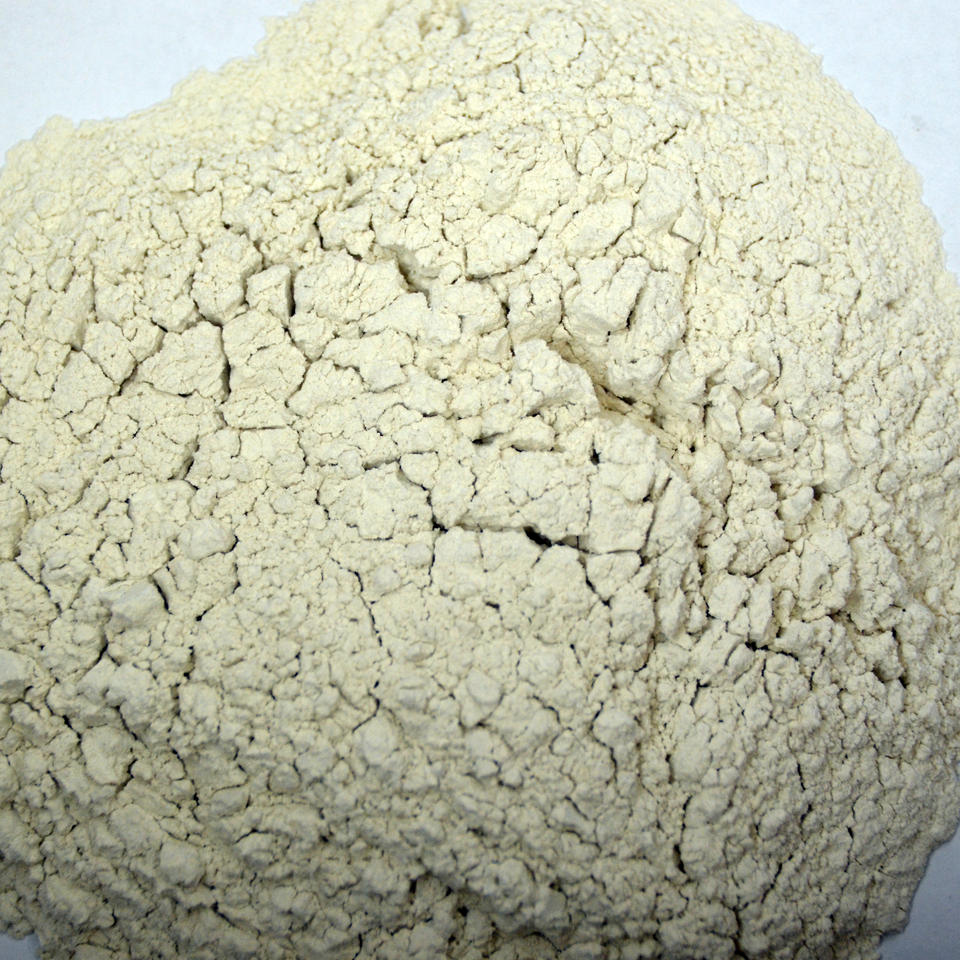

Bentonite clay, a naturally occurring clay formed from volcanic ash, is renowned for its unique properties, which include high absorbency, swelling ability, and its capacity to form a plastic mass when mixed with water. In China, two primary types of bentonite are produced sodium bentonite and calcium bentonite. Each type serves distinct purposes and finds applications across various industries, including construction, drilling, agriculture, and cosmetics.

Types of Bentonite

Sodium bentonite is favored for its high swelling capacity and is primarily used for applications that require significant absorbency, such as drilling mud, cat litter, and environmental applications like landfill sealing. Its ability to absorb water and expand makes it ideal for creating barriers and seals in various construction projects. In contrast, calcium bentonite, which has lower swelling properties, is often used for applications involving additives in food products, pharmaceuticals, and cosmetics due to its natural absorbent properties and non-toxicity.

The Production Process

The production of sodium and calcium bentonite involves several key steps. First, raw bentonite ore is extracted from natural deposits. Once mined, the clay undergoes a series of processes to refine and enhance its properties. This includes drying, crushing, and sometimes chemically treating the clay. For sodium bentonite, sodium carbonate may be added to enhance its absorbent qualities. The final product must meet strict quality control standards before being distributed to consumers.

Factory Locations

china sodium or calcium bentonite clay factories

China's bentonite clay production is concentrated mainly in regions rich in natural deposits such as Inner Mongolia, Xinjiang, and Shanxi Province. These regions are not only rich in bentonite resources but also strategically located for easy transportation to major industrial hubs. The factories in these areas are equipped with advanced machinery for processing and packaging, ensuring that the bentonite produced meets both domestic and international standards.

Market Demand

The demand for bentonite clay has been on the rise due to its extensive use in various industries. In the construction sector, bentonite is utilized in drilling fluids for oil and gas extraction, as well as in the development of waterproof barriers for landfills. The agricultural industry uses bentonite as a soil conditioner and a feed additive. Moreover, the cosmetics industry has recognized the benefits of calcium bentonite in skincare products, leading to increased demand for this type of clay.

Environmental Considerations

While the production of bentonite clay contributes significantly to local economies, environmental concerns have arisen regarding mining practices and sustainability. Responsible factories are adopting eco-friendly techniques, focusing on minimizing their environmental footprint. This includes rehabilitating mined areas and ensuring the sustainable use of natural resources. Moreover, innovation in production processes is being explored to enhance the efficiency and minimize waste.

Conclusion

As the global market for bentonite continues to expand, the sodium and calcium bentonite clay factories in China play a crucial role in meeting this demand. With their advanced production techniques and commitment to quality, these factories not only supply essential materials to various industries but also contribute to the ongoing conversation about sustainable manufacturing practices. As the industry evolves, the balance between economic benefit and environmental responsibility will be key in shaping the future of bentonite production in China.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025