Exploring Sepiolite Production in China's Leading Factories and Their Global Impact

Exploring China's Sepiolite Factories A Deep Dive into Production and Applications

Sepiolite, a naturally occurring magnesium silicate, has been gaining attention for its unique properties and diverse applications. Known for its high absorbency, thermal stability, and low density, sepiolite is widely used in industries ranging from agriculture to pharmaceuticals. China, as one of the largest producers of sepiolite globally, plays a crucial role in the supply chain and innovation of this versatile mineral. This article will explore the various aspects of sepiolite production in China, including its factories, manufacturing processes, and applications.

The Landscape of Sepiolite Production in China

China's sepiolite reserves are significant, with major deposits found in regions such as Jiangxi, Guangdong, and Yunnan. The country has established a robust mining and manufacturing infrastructure that caters to both domestic and international demands. Several factories across these regions focus on different aspects of sepiolite processing—mining, refining, and product formulation. These factories often employ advanced technology and processes to ensure high-quality production while adhering to environmental standards.

One such factory located in Jiangxi Province has set the benchmark for sustainable mining practices. By utilizing eco-friendly extraction methods and waste recycling systems, this facility minimizes its ecological footprint while maximizing output. This commitment to sustainability is essential in a world increasingly concerned with environmental impacts.

Manufacturing Processes

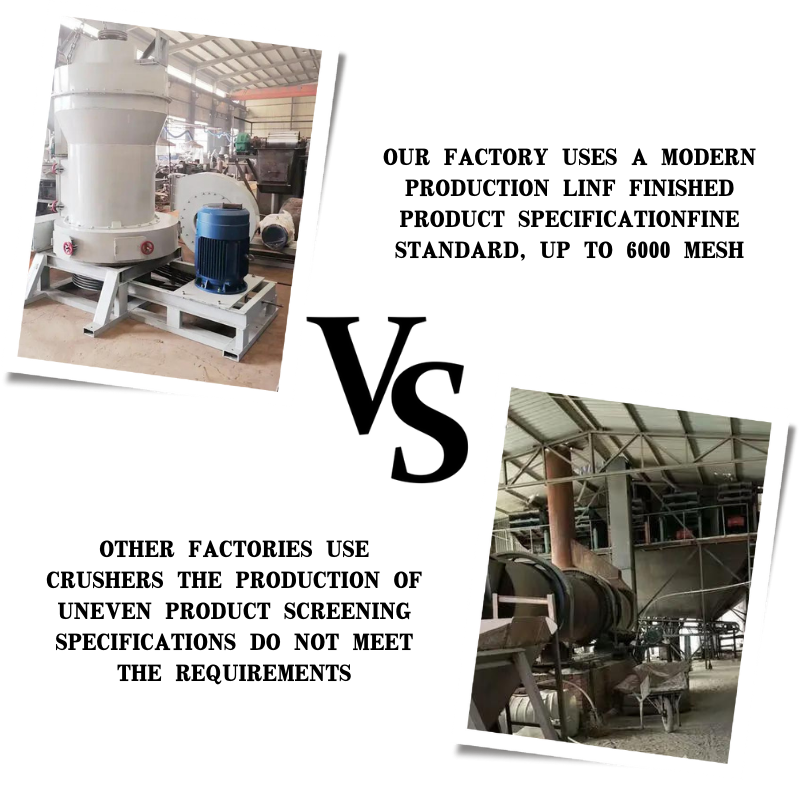

The manufacturing of sepiolite in China typically involves several key processes mining, crushing, sieving, drying, and packaging. The initial phase begins with mining, where the raw sepiolite is extracted from the earth. Following extraction, the material is crushed to a manageable size and then subjected to a sieving process to ensure uniformity in particle size, which is crucial for its applications.

china sepiolite factories

Drying is another critical step in the manufacturing process. This stage removes excess moisture, increasing the product's shelf life and ensuring its effectiveness in various applications. Advanced drying techniques, such as rotary dryers and freeze-drying, are employed to preserve the mineral's unique properties. Once dried, the sepiolite is packaged in different forms, including powder and granules, based on customer requirements.

Applications of Sepiolite

The applications of sepiolite are vast and varied. One of the most common uses is in the agricultural sector, where it acts as a soil conditioner and moisture-retaining agent. Its high absorbent properties make it ideal for improving soil structure and nutrient retention, thus promoting healthier plant growth. Additionally, sepiolite is used in the production of animal feed as an additive, helping to enhance digestion and performance in livestock.

In the industrial realm, sepiolite finds applications in the manufacturing of paints, coatings, and adhesives. Its natural, non-toxic properties make it a popular choice for eco-friendly products. Moreover, sepiolite's thermal stability enables it to be used in fire-resistant materials and insulation, serving a critical role in construction and building materials.

The pharmaceutical industry also benefits significantly from sepiolite. It is utilized as a carrier for drugs and active pharmaceutical ingredients, ensuring controlled release and effectiveness. Furthermore, its role in detoxifying agents has made it a staple in various formulations aimed at improving health outcomes.

Conclusion

In summary, China’s sepiolite factories represent a crucial segment of the global sepiolite supply chain. Through innovative manufacturing practices and a commitment to sustainability, these factories produce high-quality sepiolite that serves a myriad of applications. As industries continue to seek sustainable and effective materials, the importance of sepiolite will likely grow, securing its place as a valuable resource in both traditional and emerging markets. As we look forward, continued advancements in production technology and sustainability will ensure that China's sepiolite industry remains at the forefront of this essential mineral's evolution.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025