Perlite from China for Use in Cement Manufacturing Processes and Applications

The Role of Perlite in Cement Manufacturing A Focus on China

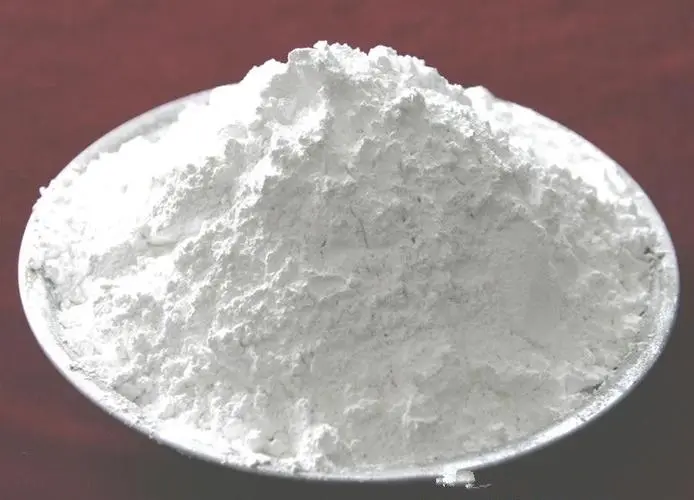

Perlite, an amorphous volcanic glass with a high water content, has gained significant attention in the construction and cement industries, particularly in China. Its unique properties make it an ideal additive in cement manufacturing, enhancing both the performance and sustainability of cement products.

The Characteristics of Perlite

Perlite is characterized by its lightweight nature and unique ability to expand when heated to high temperatures (approximately 870 to 1,000 degrees Celsius). This expansion creates a porous structure, which contributes to its excellent insulating properties. Additionally, perlite is non-combustible and has a low thermal conductivity, making it desirable for applications in fireproofing and insulation.

Applications in Cement Manufacturing

In the cement industry, perlite serves multiple purposes

1. Lightweight Aggregate Perlite can be used as a lightweight aggregate in concrete mixtures. This reduces the overall weight of the concrete, making it easier to transport and work with, particularly in large construction projects. The reduced weight can significantly decrease transportation costs and facilitate construction in regions with strict weight restrictions.

2. Improved Insulating Properties When incorporated into cement formulations, perlite enhances the thermal insulating capabilities of the final product. This is particularly valuable in regions with extreme temperatures where energy efficiency is crucial. Buildings constructed with perlite-enriched concrete can maintain comfortable indoor climates and reduce energy consumption.

3. Enhanced Workability The inclusion of perlite in concrete mixtures improves the workability and flowability of the mix. This attribute is particularly beneficial in complex architectural applications where intricate shapes and forms are required. Improved workability allows for ease of handling and application, which can ultimately lead to better construction outcomes.

china perlite for cement factory

4. Moisture Retention Perlite possesses excellent moisture-retaining properties, which can be advantageous in maintaining the hydration of concrete during curing. This ensures that the cement achieves its full strength and durability, especially in dry conditions.

Sustainability and Environmental Benefits

Perlite is a naturally occurring mineral, making it an environmentally friendly choice for manufacturers seeking to reduce their carbon footprint. The use of perlite in cement also contributes to sustainability by reducing the need for traditional aggregates, which often require extensive mining and processing.

Furthermore, the lightweight nature of perlite can lead to lower transportation emissions. As construction industries worldwide, especially in China, become increasingly focused on sustainability, the adoption of eco-friendly materials like perlite aligns with global efforts to reduce environmental impact.

China A Leader in Perlite Usage

China, as one of the largest cement producers in the world, plays a pivotal role in the utilization of perlite in cement manufacturing. With rapid urbanization and extensive infrastructure projects, the demand for lightweight and energy-efficient building materials is soaring. The Chinese cement industry has begun to recognize the benefits of incorporating perlite and other volcanic ash materials into their products.

Moreover, the Chinese government has implemented policies that promote sustainable building practices and materials. This creates a favorable environment for the integration of perlite into cement production, paving the way for innovation and improved performance in construction materials.

Conclusion

The integration of perlite into cement manufacturing represents a significant advancement in the quest for lighter, more energy-efficient, and sustainable building materials. As China continues to expand its infrastructure and urban projects, the demand for high-performance materials will undoubtedly increase. The utilization of perlite not only enhances the quality of cement products but also aligns with the growing emphasis on sustainability in the construction industry. With its myriad benefits, perlite is set to play an essential role in the future of cement manufacturing in China and beyond.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025