China's Leading Factory for High-Quality Iron Oxide Pigments and Colors

Exploring the Landscape of Iron Oxide Colors in China A Look at the Industry and Its Factories

Iron oxide pigments, renowned for their vibrant hues and environmental stability, play a crucial role in various industries, including construction, coating, plastics, and cosmetics. China, as a leading global supplier, has established a robust network of factories dedicated to the production of these colors. This article delves into the production processes, applications, and the significance of iron oxide colors factories in China.

The Production Processes

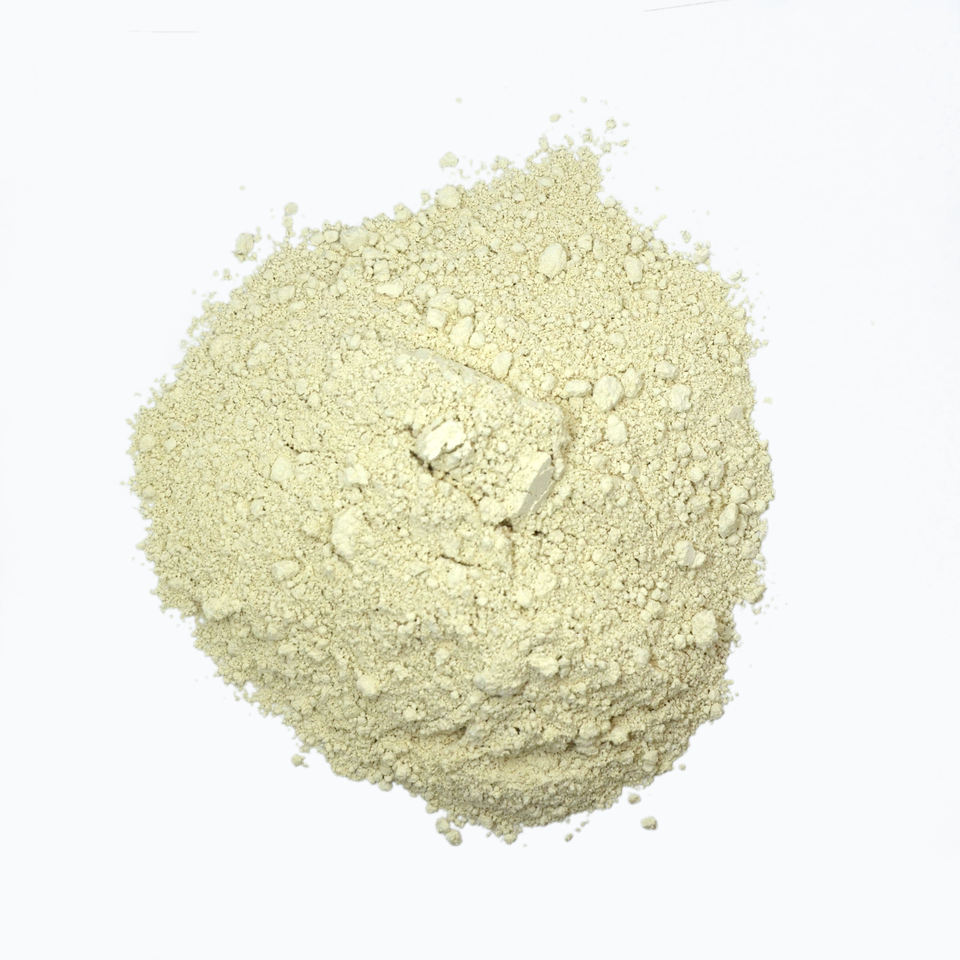

The manufacturing of iron oxide pigments involves a series of intricate processes, typically starting with the raw materials. The primary ingredient is iron, often derived from iron ore or steel-making slag. Once sourced, the iron undergoes oxidation under controlled conditions, resulting in the formation of various iron oxides such as Fe2O3 (red iron oxide), Fe3O4 (black iron oxide), and FeO (green iron oxide). These oxides are then treated, dried, and milled to produce fine powders that exhibit exceptional color consistency and stability.

Chinese factories have adopted advanced production technologies and automation to enhance the efficiency and quality of their output. Many of these facilities utilize state-of-the-art machinery for mixing, granulation, and packaging, ensuring that the final products meet international quality standards. Additionally, some factories engage in research and development to innovate new shades and improve the performance attributes of their pigments.

Applications of Iron Oxide Colors

Iron oxide pigments are incredibly versatile and find applications in numerous sectors. In the construction industry, they are widely used to color concrete, paving stones, and mortar, enhancing the aesthetic appeal of urban landscapes. Their resistance to UV rays and weathering makes them ideal for outdoor applications, contributing to the longevity of structures.

china iron oxide colors factory

In the coatings industry, iron oxide colors provide protective and decorative finishes for a variety of surfaces. Commonly found in paints and coatings, these pigments offer excellent opacity and tinting strength, enabling manufacturers to produce a wide range of colors. The stability of iron oxide colors also ensures that they do not fade over time, making them a preferred choice for both industrial and decorative coatings.

In the plastic industry, iron oxide pigments are utilized to impart color to products ranging from toys to automotive parts. They are favored due to their non-toxicity and compliance with environmental regulations, ensuring that end products are safe for consumers. Furthermore, these pigments are also employed in the cosmetic industry, where shades of iron oxide are used in makeup products like foundations and blushes, allowing for natural skin tones and vibrant colors.

Environmental and Economic Impact

The iron oxide colors industry in China not only significantly contributes to the economy but also emphasizes sustainability. Many factories are adopting environmentally friendly practices, such as waste recycling and pollution control measures. This shift towards greener production methods helps mitigate the environmental impact commonly associated with industrial manufacturing.

Moreover, the strategic positioning of iron oxide factories in China enhances their ability to serve both domestic and international markets. As global demand continues to rise for environmentally friendly pigments, China's robust supply chain allows for efficient distribution and competitive pricing. This ensures that Chinese products remain at the forefront of the global market for iron oxide colors.

Conclusion

The iron oxide colors industry in China exemplifies a successful blend of technology, artistry, and sustainability. Through efficient production processes and innovative applications, Chinese factories play an essential role in supplying high-quality pigments that meet the diverse needs of various industries. As the world continues to evolve towards sustainability, the commitment of these factories to environmentally friendly practices positions them as leaders in the pigment sector. This, combined with their ability to adapt to market demands, places China at the forefront of the global iron oxide color industry, ensuring a vibrant future for color manufacturing.

Share

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025