china granulated activated carbon factory

The Rise of Granulated Activated Carbon Factories in China

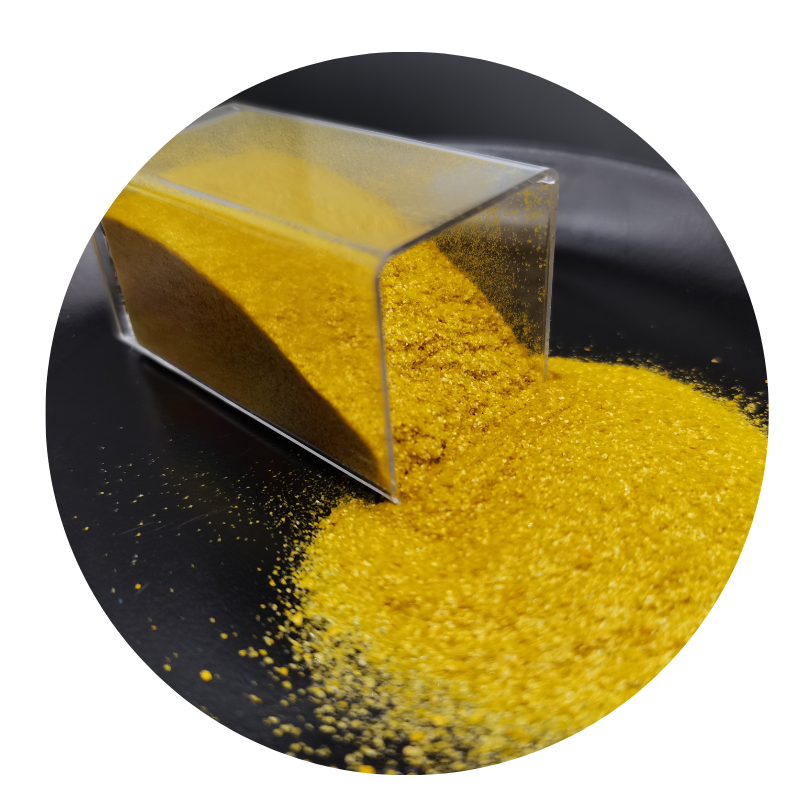

In recent years, the demand for granulated activated carbon (GAC) has witnessed unprecedented growth, particularly in China, where industrial development and environmental concerns converge. Granulated activated carbon is a highly porous material derived from carbonaceous sources through a process of activation. It is extensively used in water treatment, air purification, and various industrial applications. As industries increasingly focus on sustainability and pollution control, the significance of GAC and the factories producing it has become more pronounced.

The Importance of Granulated Activated Carbon

Granulated activated carbon is effective in adsorbing a wide range of contaminants, including volatile organic compounds (VOCs), heavy metals, and other pollutants. Its versatility makes it indispensable in numerous sectors, including municipal water treatment plants, wastewater treatment facilities, the food and beverage industry, pharmaceuticals, and air purification systems. In China, where industrial growth has led to significant environmental challenges, GAC plays a crucial role in mitigating pollution and ensuring compliance with stricter environmental regulations.

The Chinese government has recognized the growing environmental issues and has implemented stringent laws and standards to curb pollution. This has spurred the growth of granulated activated carbon factories across the nation, resulting in an increased output of high-quality GAC products. These factories not only focus on meeting the domestic demand but are also expanding their reach to international markets, positioning China as a major player in the global activated carbon industry.

The Process of Manufacturing Granulated Activated Carbon

The production of granulated activated carbon involves several key stages. Initially, organic materials, often sourced from coconut shells, coal, or wood, are carbonized. This process involves heating the material in an oxygen-deficient environment to remove non-carbon elements, creating a char. Following carbonization, the char undergoes activation, which enhances its porosity and surface area. Through either physical activation using steam or chemical activation using various chemicals, the char transforms into activated carbon.

The quality of granulated activated carbon produced in Chinese factories is often determined by the raw materials used and the precision of the activation process. Modern factories are increasingly adopting advanced technologies and stringent quality control measures to ensure that the GAC meets both domestic and international standards. As a result, Chinese manufacturers are gaining a reputation for producing high-quality activated carbon, which is vital in maintaining competitive pricing in the global market.

china granulated activated carbon factory

Innovations and Technological Advancements

The Chinese activated carbon industry is undergoing significant transformations, driven by technological advancements and the growing need for eco-friendly production processes. Many factories are exploring the use of renewable energy sources and efficient waste management systems in their operations. These innovations not only reduce production costs but also minimize the environmental footprint of manufacturing processes.

Moreover, research and development in the field of activated carbon are leading to the creation of specialized GAC products, tailored for specific applications. For instance, research has focused on enhancing the adsorption capabilities of GAC through chemical modification and impregnation techniques. This has opened new avenues for utilizing GAC in advanced applications, such as in the pharmaceutical industry for drug purification and in the automotive sector for vehicle emissions control.

Challenges Facing the Industry

Despite the promising growth of granulated activated carbon factories in China, the industry is not without its challenges. Fluctuating raw material prices and the need for compliance with increasingly strict environmental regulations can pose significant hurdles. Additionally, the market is becoming more competitive, with numerous players vying for a share, both domestically and internationally. This necessitates that factories continuously innovate and improve their production processes to maintain a competitive edge.

Another challenge lies in the perception of activated carbon’s efficacy and safety, particularly among consumers and small industries unaware of its benefits. Greater efforts in outreach and education are essential to promote the advantages of using granulated activated carbon for purification and adsorption purposes.

Conclusion

The growth of granulated activated carbon factories in China is a reflection of the country’s commitment to addressing environmental challenges while supporting industrial growth. As these factories evolve through technological advancements and innovations, they are set to play an even more critical role in sustainability efforts—both domestically and globally. The future of granulated activated carbon production in China looks promising, with potential for further growth, enhanced quality, and increased contributions to environmental protection efforts worldwide.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025