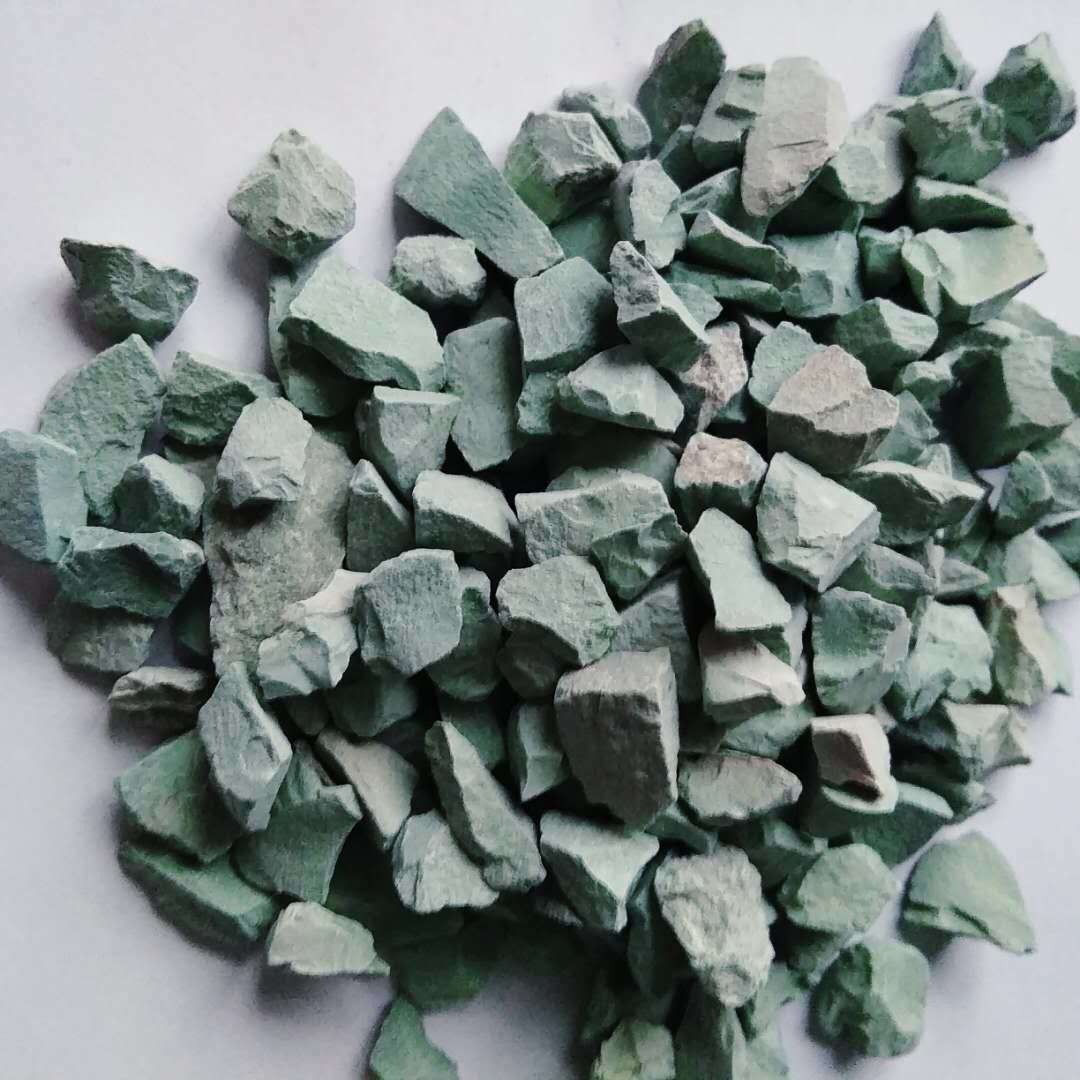

china calcin kaolin manufacturer

China’s Kaolin Production Insights into the Calcination Process and Leading Manufacturers

Kaolin, commonly referred to as china clay, is a versatile mineral used in various industries ranging from ceramics to paints and paper manufacturing. China is one of the largest producers and exporters of kaolin globally, with a particular focus on calcined kaolin, which is produced through the calcination process, enhancing its properties for industrial applications. This article explores the calcination process of kaolin and highlights some of the leading manufacturers in China.

Understanding Kaolin

Kaolin is primarily composed of kaolinite, a mineral that is a type of clay. Its unique properties, including whiteness, fine particle size, and inertness, make it an essential ingredient in numerous applications. When kaolin undergoes calcination, it is subjected to high temperatures (typically between 600°C and 1200°C), leading to significant physical and chemical changes. This process transforms kaolinite into metakaolin, enhancing its performance, particularly in terms of brightness, discharge characteristics, and rheological properties.

The Calcination Process

The calcination of kaolin is a carefully controlled process designed to maximize the quality and ensure the performance characteristics desired for industrial applications. The process begins with the selection of high-purity kaolin that has low impurities and fine particle size. It is then dried and milled to a uniform consistency before being subjected to high temperatures.

During the heating stage, kaolinite loses water and undergoes structural changes that eliminate impurities, resulting in a product that exhibits increased brightness and whiteness ideal for use in ceramics and paints. The process not only modifies the chemical composition but also enhances properties like thermal stability and plasticity, making calcined kaolin a valuable additive in various industries.

Applications of Calcined Kaolin

Calcined kaolin has numerous applications across different sectors. In the ceramics industry, it acts as a flux, helping to lower the melting point of raw materials and increase the strength and durability of finished products. In the paper industry, calcined kaolin is used as a filler and coating pigment, improving brightness and smoothness of the paper. It is also increasingly used in plastics and rubber, where it enhances the mechanical properties of the final products.

china calcin kaolin manufacturer

In the construction sector, calcined kaolin is utilized in cement and concrete applications, playing a critical role in improving workability and increasing strength. Additionally, with the rising demand for eco-friendly materials, calcined kaolin is gaining traction within the green building movement due to its sustainable properties and performance advantages.

Leading Manufacturers in China

China is home to several prominent manufacturers specializing in kaolin production, particularly calcined kaolin. Some of the notable companies include

1. Ashapura Group With a significant production capacity, Ashapura is a leading supplier of calcined and non-calcined kaolin. The company focuses on quality and innovation, offering products tailored to meet specific industry needs.

2. Imerys As a global leader in mineral-based solutions, Imerys operates several facilities in China. They produce high-quality calcined kaolin products for a variety of uses, maintaining a strong commitment to research and development.

3. Sibelco This company has established a strong presence in the kaolin market in China, providing a wide range of calcined kaolin products that cater to industries like ceramics, paper, and plastic.

4. KaMin LLC With a robust infrastructure and advanced processing techniques, KaMin specializes in high-performance calcined kaolin. Their focus on sustainability and quality has positioned them as a trusted supplier in both domestic and international markets.

Conclusion

The calcination of kaolin is a vital process that enhances the versatility and applicability of this mineral across multiple sectors. As the world continues to seek sustainable and high-performance materials, the role of calcined kaolin will likely become even more significant. With leading manufacturers in China consistently innovating and investing in quality, the future of kaolin production looks promising, ensuring that this essential mineral continues to meet the demands of various industries worldwide.

Share

-

Vibrant Dyed Gravel: Colorful Stone for Landscaping & DecorNewsAug.11,2025

-

Premium Ceramsite for Plants & Hydroponics - Ideal Growing MediaNewsAug.10,2025

-

Premium Mineral Sepiolite Powder: Versatile Adsorbent & FillerNewsAug.09,2025

-

Premium Talcum Powder - Smoothness & Purity GuaranteedNewsAug.08,2025

-

Premium Fly Ash Powder: Ideal Admixture for Strong ConcreteNewsAug.07,2025

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025