china barite and bentonite factories

The Barite and Bentonite Industry in China An Overview of Factories and Manufacturing

China has emerged as a global leader in the production and supply of various industrial minerals, particularly barite and bentonite. These two minerals serve a crucial role across multiple sectors, including oil and gas, construction, and agriculture. This article aims to provide insight into the barite and bentonite factories in China, highlighting their significance, manufacturing processes, and market trends.

Understanding Barite and Bentonite

Barite is a mineral composed of barium sulfate (BaSO4) and is primarily used in drilling fluids for oil and gas extraction. Its high density makes it an essential component in ensuring that drilling fluids maintain their properties and optimize the extraction process. Additionally, barite is utilized in the production of paints, rubber, glass, and ceramics.

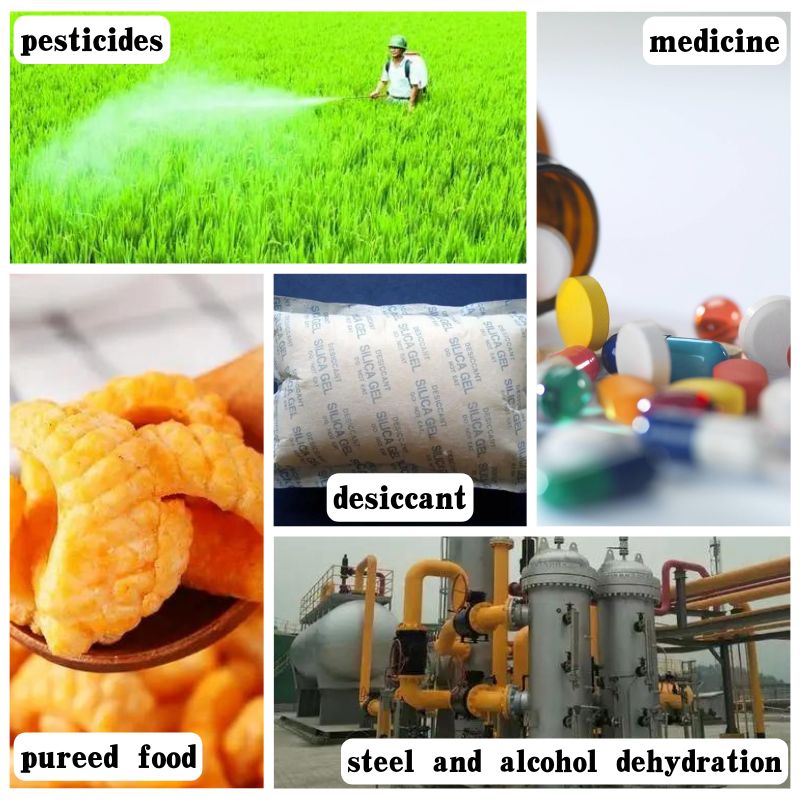

Bentonite, on the other hand, is a clay mineral that is primarily composed of montmorillonite. It has excellent swelling properties and is widely used in various applications, including drilling mud, foundry sand, cat litter, and as a binding agent in various industries. The ability to absorb water and expand makes bentonite particularly valuable in the construction industry, where it is used for waterproofing and sealing.

The Landscape of Barite and Bentonite Factories in China

China is home to a vast number of barite and bentonite manufacturers, ranging from small-scale operations to large industrial complexes. The primary production regions for these minerals include southern and western provinces such as Guangxi, Guizhou, and Xinjiang, where rich deposits can be found.

These factories employ advanced mining and processing technologies to extract and refine barite and bentonite. The typical manufacturing process includes several stages extraction, crushing, grinding, and packaging. The production begins with the mining of raw materials, which are then crushed to smaller sizes. After crushing, the materials undergo various grinding processes to create fine powders suitable for industrial applications.

Quality control is paramount in the production of barite and bentonite. Manufacturers in China adhere to strict quality standards to ensure that their products meet the specifications required by international markets. This typically involves rigorous testing of the mineral composition, particle size distribution, and physical properties.

china barite and bentonite factories

Market Trends and Demand

The demand for barite and bentonite has been steadily increasing, driven by growth in the oil and gas sector, construction, and other industries. The rise in global energy consumption and the subsequent increase in drilling activities have spurred the need for high-quality drilling fluids, consequently boosting the barite market.

Similarly, the expanding construction industry, particularly in developing countries, has created a robust demand for bentonite. Its application in waterproofing construction projects and as a binding agent in various materials is a significant factor contributing to its popularity.

China’s strategic position as a major exporter of barite and bentonite further enhances its significance in the global market. The nation supplies these minerals to various countries, including the United States, Europe, and Southeast Asia, thereby playing a critical role in meeting international demand.

Challenges and Environmental Considerations

While the barite and bentonite factories in China are a vital part of the industrial landscape, they also face several challenges. Environmental concerns related to mining practices have garnered attention from both local communities and regulatory bodies. The potential for soil erosion, water pollution, and habitat destruction requires manufacturers to adopt sustainable mining practices.

Moreover, fluctuations in global prices for barite and bentonite can impact profitability for manufacturers. As a result, companies are increasingly looking to innovate and improve efficiency in their operations to remain competitive in the global market.

Conclusion

The barite and bentonite industry in China is a significant contributor to the nation's economy, with a well-established network of factories and a comprehensive manufacturing process. As global demand continues to rise, the importance of these minerals is likely to increase. However, it is essential for manufacturers to balance industrial growth with environmental sustainability to ensure that the benefits of this industry can be enjoyed in the long term.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025