calcium hydroxide manufacturer

Calcium Hydroxide Manufacturer A Comprehensive Overview

Calcium hydroxide, commonly known as slaked lime or hydrated lime, is an important chemical compound with the formula Ca(OH)₂. It is a white powder that is typically produced by slaking quicklime, which is calcium oxide (CaO). This versatile substance is widely used in various industries, including construction, water treatment, food processing, and environmental remediation. The role of calcium hydroxide manufacturers is crucial in supplying this essential material to meet the demands of these diverse applications.

Manufacturing Process

The production of calcium hydroxide begins with the extraction of limestone (calcium carbonate, CaCO₃) from quarries. The limestone is then heated in a kiln at temperatures around 900 to 1000 degrees Celsius. This process, known as calcination, results in the decomposition of limestone into quicklime (CaO) and carbon dioxide (CO₂). Once the quicklime is obtained, it is mixed with water in a process known as slaking. The reaction between quicklime and water produces calcium hydroxide

\[ \text{CaO} + \text{H}_2\text{O} \rightarrow \text{Ca(OH)}_2 \]

The resulting calcium hydroxide can be used in both powder and slurry forms, and manufacturers often ensure the quality and consistency of their products through rigorous testing and quality control measures.

Applications of Calcium Hydroxide

1. Construction Industry Calcium hydroxide is a key ingredient in building materials, particularly in mortars and plasters. It contributes to the strength and durability of these materials when it undergoes carbonation, reacting with carbon dioxide in the air to form calcium carbonate. Additionally, it is used in soil stabilization for road construction and as an additive in cement to enhance its properties.

2. Water Treatment In municipal and industrial water treatment facilities, calcium hydroxide acts as a coagulant and a pH adjuster. It helps in the removal of heavy metals and other contaminants from wastewater by precipitating them out of solution. Furthermore, calcium hydroxide is used to soften water and make it more palatable for drinking.

3. Food Industry In the food processing sector, calcium hydroxide is involved in the preparation of various products. It is used in the production of antacids and can also serve as a raising agent in baking. Moreover, it plays a role in food preservation, particularly in the treatment of fruits and vegetables to inhibit spoilage.

calcium hydroxide manufacturer

4. Environmental Remediation Calcium hydroxide is employed in the treatment of acidic soils and in the neutralization of acidic waste in industrial processes. Its ability to raise pH levels makes it useful in stabilizing contaminated sites, ensuring the safety of groundwater and soil.

5. Chemical Manufacturing As a reagent, calcium hydroxide is used in producing other chemicals, including calcium-based compounds and hydroxides. Its alkaline properties make it an essential component in many chemical reactions.

Choosing a Reliable Manufacturer

When selecting a calcium hydroxide manufacturer, several factors should be considered

- Quality Assurance Look for manufacturers who adhere to strict quality control standards and have certifications that guarantee the purity and consistency of their products.

- Technical Expertise A manufacturer with a strong technical background can provide valuable insights into the best applications and potential modifications to suit specific needs.

- Sustainability Practices In today’s environmentally conscious market, choose manufacturers that operate with sustainability in mind, utilizing eco-friendly processes and sourcing materials responsibly.

- Customer Support Good manufacturers often provide comprehensive support and guidance to their clients, from initial inquiries to post-purchase assistance.

Conclusion

Calcium hydroxide is an essential chemical with a wide array of applications across multiple industries. The role of calcium hydroxide manufacturers is vital in ensuring a steady supply of high-quality products that meet the unique requirements of each sector. By investing in advanced manufacturing processes and maintaining strong quality control standards, these manufacturers contribute significantly to the economic growth and environmental sustainability of their communities. The importance of partnering with reliable calcium hydroxide manufacturers cannot be overstressed, as they play a key role in the efficiency and success of numerous industrial applications.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

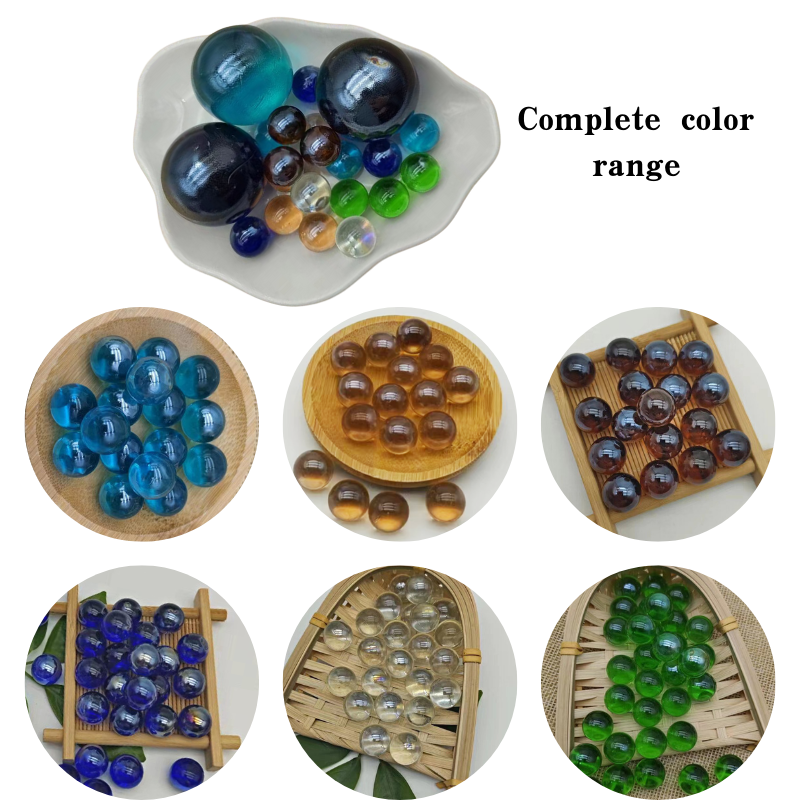

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025