Understanding the Benefits and Applications of Calcined Talc in Various Industries

The Role of Calcined Talc in Various Industries

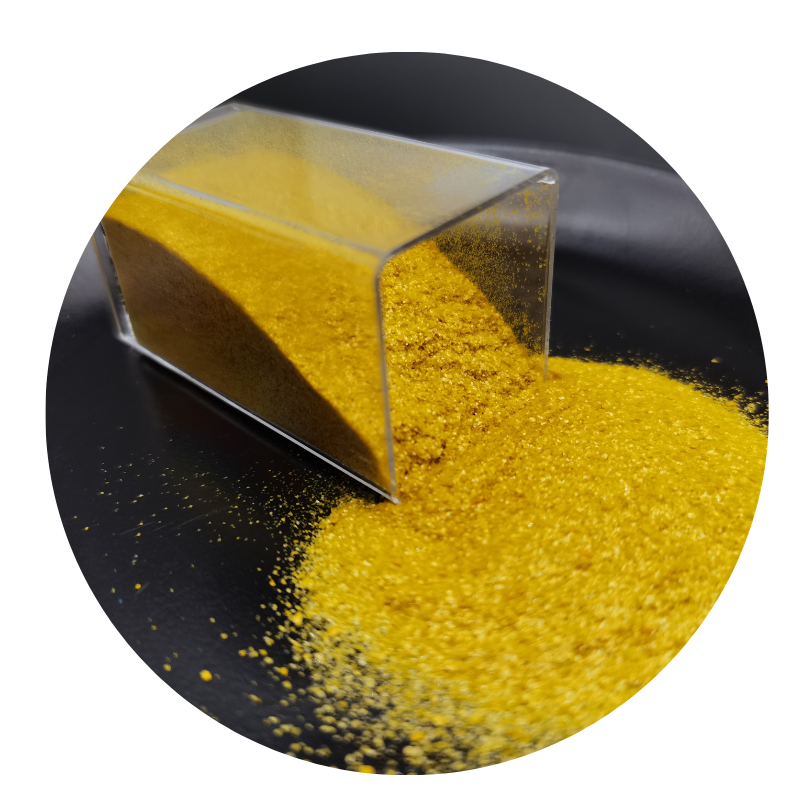

Calcined talc is a refined form of talc that has undergone a heating process, enhancing its properties and making it suitable for a wide array of applications. Talc, a naturally occurring mineral, is primarily composed of magnesium, silicon, and oxygen. When talc is calcined, it is subjected to high temperatures, typically between 800°C to 1200°C, resulting in the removal of moisture and other volatiles. This process leads to a product with improved structural integrity, lower plasticity, and enhanced thermal stability, making calcined talc a valuable ingredient in many industrial sectors.

Properties and Benefits of Calcined Talc

Calcined talc exhibits several key properties that distinguish it from its untreated counterpart. One of the most notable characteristics is its increased purity. The calcination process can reduce impurities such as iron and other metallic oxides, yielding a product that is predominantly comprised of talc and silica. Additionally, this heightened purity contributes to enhanced whiteness, which is particularly important in industries where aesthetics matter, such as in plastics and paints.

Another significant benefit of calcined talc is its excellent lubricating properties. This characteristic is due to its lamellar structure, allowing layers to slide over one another easily. As a result, calcined talc is extensively used as a lubricant in various applications, including the manufacturing of rubber and plastics, where it helps to reduce friction during processing.

Furthermore, calcined talc boasts impressive thermal resistance. This makes it an ideal filler material in fire-resistant products, such as roofing materials, plastics, and even textiles. Its ability to withstand high temperatures without degrading safeguards the integrity of the final product, making it a preferred choice in environments where heat is a concern.

Applications Across Industries

calcined talc

One of the largest markets for calcined talc is the plastics industry. It is commonly used as a filler to improve the mechanical and thermal properties of plastic products. By incorporating calcined talc, manufacturers can produce lighter and stronger plastic components, which are essential in automotive and consumer goods. Moreover, calcined talc enhances the durability and reduces the cost of plastics, making it a favored option for product developers.

In the paint and coating sector, calcined talc serves multiple purposes, including acting as a pigment extender and improving the texture and smoothness of the paint. Its high opacity and white color contribute to vibrant finishes, while its low oil absorption ensures optimal application properties. As environmental concerns rise, the use of calcined talc in paint formulations can provide a more sustainable alternative to synthetic fillers.

Additionally, the paper industry harnesses the benefits of calcined talc as a filler and coating agent. It enhances printability and provides a smooth surface for various printing techniques. The mineral's ability to improve brightness and opacity is critical for producing high-quality paper products, which are essential in publishing and packaging applications.

The cosmetics industry also utilizes calcined talc, particularly in products like face powders and body powders. Its soft texture and absorbent properties help to create smooth application and a matte finish, while also providing a lightweight feel. Additionally, due to its inert nature, calcined talc is considered safe for use in cosmetic formulations.

Conclusion

In conclusion, calcined talc is an indispensable material across various industries, enriching products with its unique properties. As a versatile mineral, it enhances the performance and quality of plastics, paints, paper, and cosmetics, among others. As industries continue to push for improvements in product performance and environmental sustainability, the demand for high-quality calcined talc is likely to grow. Its ability to adapt to evolving technological needs underscores its importance in modern manufacturing processes, ensuring that calcined talc remains a key player in the materials science landscape.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025