Feb . 05, 2025 05:42

Back to list

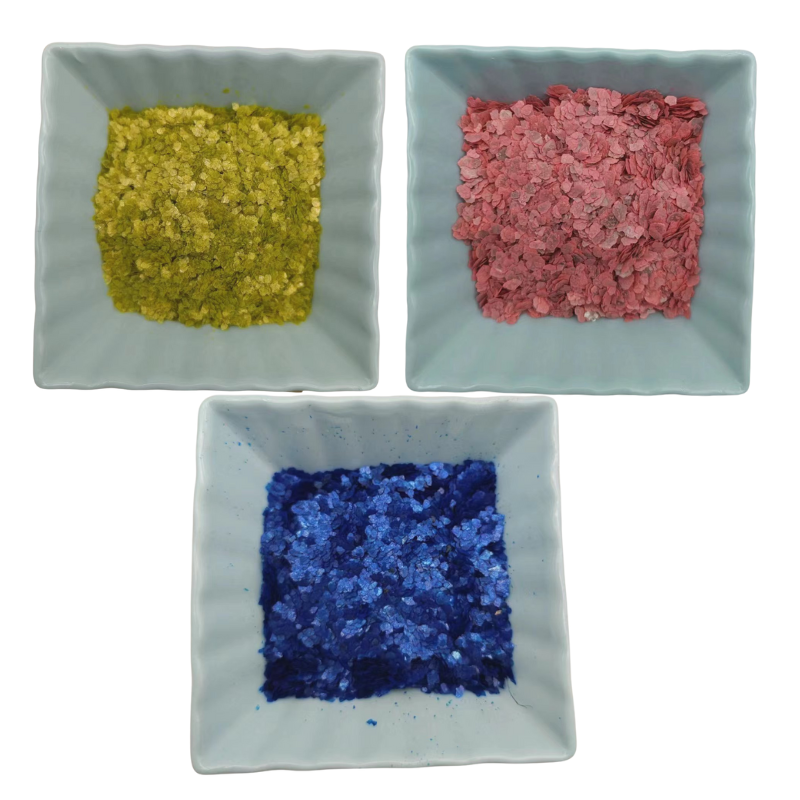

Iron powder iron oxide powder pig iron powder heated iron powder ultrafine iron powder

Calcium carbonate, known in the industry as CaCO3, is a highly versatile material widely used across various sectors such as construction, paper, plastics, and pharmaceuticals. The market for CaCO3 powder continues to evolve with fluctuating prices influenced by multiple factors. Understanding the dynamics of CaCO3 pricing requires insight into the production processes, market demand, and global supply chains.

Market demand is another pivotal aspect influencing CaCO3 powder prices. The rise of industries such as plastics, especially in developing countries, has bolstered demand, leading manufacturers to adjust their pricing strategies. Additionally, the shift towards sustainable and recyclable products is pushing industries to seek greener alternatives, impacting traditional CaCO3 applications and subsequently its market price. Global supply chain dynamics, including geopolitical tensions, trade policies, and pandemic-related disruptions, have also affected CaCO3 powder pricing. Restrictions on exports, tariffs, and changes in import regulations can lead to supply shortages, prompting price hikes. Conversely, increased production capacity in regions with fewer trade restrictions can lead to a surplus, reducing prices. A crucial aspect of understanding CaCO3 powder pricing is the expertise of manufacturers and distributors in ensuring quality and consistency. Companies with a long-standing reputation for high-quality products often command higher prices due to their reliability and the trust they have built in their customer base. Their products often come with certifications and quality assurances that lower-cost providers might not offer. Trustworthiness in the supply of CaCO3 powder is established through clear communication of product specifications and performance. Suppliers that provide transparent data on the composition and sourcing of their CaCO3 products gain a competitive edge in the market. Ensuring traceability in their supply chains also enhances their credibility, which can be a decisive factor for industry buyers focused on compliance and sustainability. In conclusion, the price of CaCO3 powder is determined by a combination of factors including raw material costs, technological advancements, transportation logistics, market demand, global supply chain conditions, and the credibility of suppliers. Companies aiming to secure competitive pricing for CaCO3 must remain informed about market trends, embrace technological improvements, and maintain strong relationships with reliable suppliers to ensure a steady, high-quality supply. This strategic approach will enable businesses to navigate the complexities of the CaCO3 market effectively, optimizing both cost and performance benefits for their diverse applications.

Market demand is another pivotal aspect influencing CaCO3 powder prices. The rise of industries such as plastics, especially in developing countries, has bolstered demand, leading manufacturers to adjust their pricing strategies. Additionally, the shift towards sustainable and recyclable products is pushing industries to seek greener alternatives, impacting traditional CaCO3 applications and subsequently its market price. Global supply chain dynamics, including geopolitical tensions, trade policies, and pandemic-related disruptions, have also affected CaCO3 powder pricing. Restrictions on exports, tariffs, and changes in import regulations can lead to supply shortages, prompting price hikes. Conversely, increased production capacity in regions with fewer trade restrictions can lead to a surplus, reducing prices. A crucial aspect of understanding CaCO3 powder pricing is the expertise of manufacturers and distributors in ensuring quality and consistency. Companies with a long-standing reputation for high-quality products often command higher prices due to their reliability and the trust they have built in their customer base. Their products often come with certifications and quality assurances that lower-cost providers might not offer. Trustworthiness in the supply of CaCO3 powder is established through clear communication of product specifications and performance. Suppliers that provide transparent data on the composition and sourcing of their CaCO3 products gain a competitive edge in the market. Ensuring traceability in their supply chains also enhances their credibility, which can be a decisive factor for industry buyers focused on compliance and sustainability. In conclusion, the price of CaCO3 powder is determined by a combination of factors including raw material costs, technological advancements, transportation logistics, market demand, global supply chain conditions, and the credibility of suppliers. Companies aiming to secure competitive pricing for CaCO3 must remain informed about market trends, embrace technological improvements, and maintain strong relationships with reliable suppliers to ensure a steady, high-quality supply. This strategic approach will enable businesses to navigate the complexities of the CaCO3 market effectively, optimizing both cost and performance benefits for their diverse applications.

Share

Latest news

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025