barite powder factory

The Barite Powder Factory A Vital Contributor to Industry

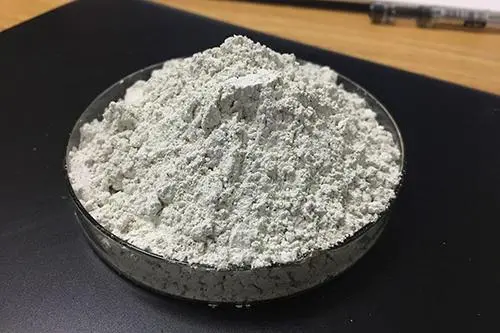

Barite, a mineral composed of barium sulfate (BaSO4), is renowned for its high density and various industrial applications. It is often utilized as a weighting agent in drilling fluids, a pigment in paint, and even as an additive in plastics. Thus, the production of barite powder is crucial in supporting numerous industries, including oil and gas, construction, and manufacturing. This article delves into the significance of a barite powder factory, its processes, and its contributions to various sectors.

A barite powder factory typically operates with a multi-faceted approach, involving extraction, processing, and distribution. The first step in producing barite powder is mining. Barite is primarily found in sedimentary deposits, often associated with lead and zinc ores. Mines are established in regions where barite is abundant, and the extraction process relies on techniques such as open-pit mining, which provides access to shallow deposits, or underground mining for deeper reserves.

Once extracted, raw barite is transported to the factory, where the real transformation begins. The processing typically includes crushing, grinding, and classifying the mineral to achieve the desired particle size. This is an essential step, as the fine-tuning of particle size directly impacts the powder's applications. For instance, barite powder utilized in oil drilling must have specific properties, such as uniform particle distribution and minimal impurities to ensure optimal performance in high-pressure environments.

The grinding process is conducted using specialized equipment such as Raymond mills or ball mills, which refine the barite into a fine powder. After grinding, the barite undergoes classification to separate different particle sizes. The finest grades are typically used in high-end applications, while coarser fractions may find their place in construction materials or as fillers in various industrial products.

barite powder factory

Quality control is integral to the operations of a barite powder factory. Given the diverse applications of barite, ensuring the product meets industry standards is paramount. Laboratories within the facility conduct rigorous testing on the powder for parameters such as purity, density, and viscosity. This quality assurance process not only helps in maintaining product integrity but also builds trust with clients, fostering long-term business relationships.

A barite powder factory also plays a pivotal role in the environmental landscape. With rising awareness regarding sustainable practices, many factories are adopting eco-friendly measures in their operations. This includes minimizing waste through recycling materials, optimizing energy consumption during grinding processes, and employing water treatment systems to manage the use of water during mineral processing. Such initiatives not only reduce the factory's ecological footprint but also enhance its reputation in an increasingly environmentally-conscious market.

Sold both domestically and internationally, barite powder finds its way into a myriad of applications. In the oil and gas industry, it serves as a crucial component in drilling fluids, where its high density helps to stabilize the borehole and prevent blowouts during drilling operations. In construction, barite is used in cement production and as a filler in different concrete mixtures, enhancing their properties and performance. Furthermore, barite powder is also utilized in the manufacturing of plastics and rubber, where it contributes to the material’s strength and durability.

With the ongoing developments in technology and material science, the demand for specialized barite powders continues to grow. Innovations in mining and processing techniques are paving the way for more efficient production methods, which can yield purer and more finely milled products. This evolution not only caters to traditional markets but also opens doors to new applications, further diversifying the use of barite powder in emerging industries.

In conclusion, the barite powder factory stands as a cornerstone in the production of a vital industrial mineral. From extraction to processing and quality control, each step is crucial in delivering a product that meets the diverse needs of various sectors. As industries evolve and new applications are discovered, the role of barite powder—and consequently, the factories that produce it—will only become more significant, underscoring the importance of this unassuming mineral in our modern world.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025