Jan . 09, 2025 13:56

Back to list

Large quantities of wholesale barite powder can be customized specifications

Barite powder, often overlooked in the shadow of more well-known industrial minerals, serves as a critical component in various industries, offering unique properties that are invaluable in multiple applications. Derived from the mineral barium sulfate, barite powder stands out for its high specific gravity and chemical inertness. These attributes have made it indispensable, particularly in the drilling, paint, and rubber industries.

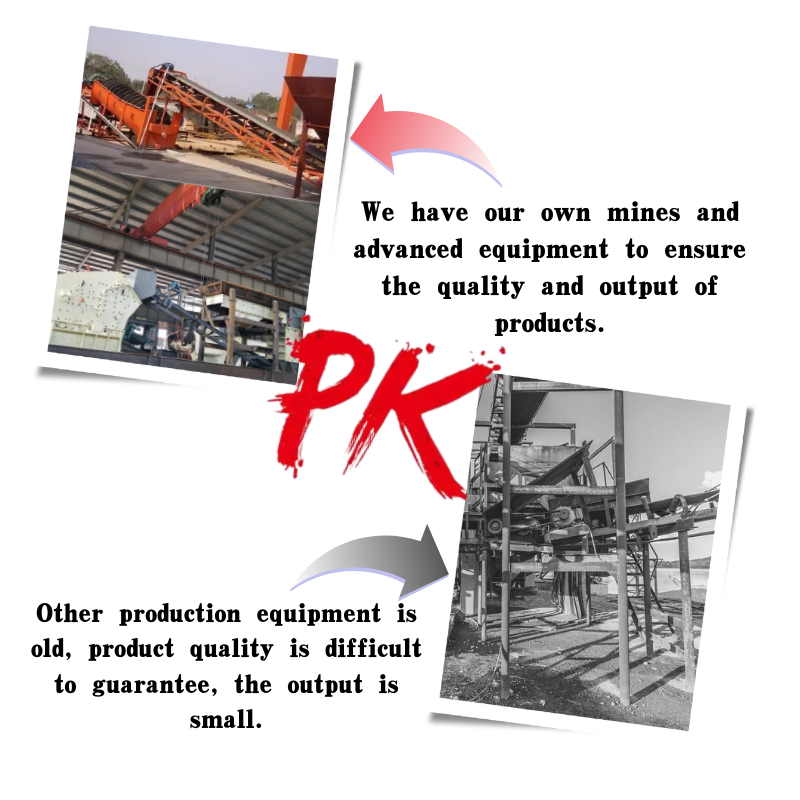

From a technical standpoint, the processing of barite powder involves rigorous quality control to maintain uniform particle size and purity, factors crucial for its effectiveness in various applications. Suppliers and manufacturers that excel in refining and delivering high-grade barite are paramount within these industries. Therefore, purchasing barite powder from reputable sources guarantees that the mineral's intrinsic benefits are fully realized in its application. Moreover, sustainability practices are increasingly becoming a focal point in the production and use of barite powder. Ensuring that the mining and processing of barite are conducted in an environmentally friendly manner not only preserves ecological balance but also aligns with global industry standards aimed at reducing carbon footprints. Barite powder's diverse capabilities highlight the importance of collaboration between mining entities, and application-driven industries, in optimizing its usage to enhance product performance while maintaining economic and environmental responsibility. As awareness grows around the multifaceted benefits of barite powder, industries are beginning to explore novel applications, unlocking even greater potential for this unique mineral. Thus, barite powder remains not only an essential industrial material but also a catalyst for innovation across various sectors.

From a technical standpoint, the processing of barite powder involves rigorous quality control to maintain uniform particle size and purity, factors crucial for its effectiveness in various applications. Suppliers and manufacturers that excel in refining and delivering high-grade barite are paramount within these industries. Therefore, purchasing barite powder from reputable sources guarantees that the mineral's intrinsic benefits are fully realized in its application. Moreover, sustainability practices are increasingly becoming a focal point in the production and use of barite powder. Ensuring that the mining and processing of barite are conducted in an environmentally friendly manner not only preserves ecological balance but also aligns with global industry standards aimed at reducing carbon footprints. Barite powder's diverse capabilities highlight the importance of collaboration between mining entities, and application-driven industries, in optimizing its usage to enhance product performance while maintaining economic and environmental responsibility. As awareness grows around the multifaceted benefits of barite powder, industries are beginning to explore novel applications, unlocking even greater potential for this unique mineral. Thus, barite powder remains not only an essential industrial material but also a catalyst for innovation across various sectors.

Share

Next:

Latest news

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025