Jan . 09, 2025 12:28

Back to list

aluminium oxide al2o3 powder

Aluminium oxide (Al2O3) powder stands as a cornerstone material in various industries due to its exceptional properties and versatile applications. Renowned for its high hardness and thermal stability, Al2O3 powder is pivotal in the manufacture of cutting-edge products that range from electronics to aerospace components.

Experts in materials science and engineering frequently conduct in-depth studies on aluminium oxide powder to explore its emerging applications. Continuous research ensures that the powder’s formulation meets the evolving demands of new technologies, affirming its status as a material that adapts to innovation. Trust in aluminium oxide powder is well-founded through its extensive application history and compliance with stringent industry standards. Manufacturers and consumers alike rely on its consistent performance and safety record, which underscores its credibility in critical industrial processes. Professionals considering the integration of Al2O3 powder into their products should seek suppliers with proven expertise and a commitment to quality control. An authoritative supplier will not only furnish the material but also provide technical guidance tailored to specific application needs, ensuring that the unique properties of aluminium oxide fully enhance the intended product functionality. In conclusion, aluminium oxide Al2O3 powder distinguishes itself through unmatched expertise, authoritativeness, and trustworthiness. This material continues to drive innovation across industries, grounded in real-world experience and rigorous scientific exploration. It is a testament to the possibilities afforded by advanced materials science, promising a robust future for a wide array of technological advancements.

Experts in materials science and engineering frequently conduct in-depth studies on aluminium oxide powder to explore its emerging applications. Continuous research ensures that the powder’s formulation meets the evolving demands of new technologies, affirming its status as a material that adapts to innovation. Trust in aluminium oxide powder is well-founded through its extensive application history and compliance with stringent industry standards. Manufacturers and consumers alike rely on its consistent performance and safety record, which underscores its credibility in critical industrial processes. Professionals considering the integration of Al2O3 powder into their products should seek suppliers with proven expertise and a commitment to quality control. An authoritative supplier will not only furnish the material but also provide technical guidance tailored to specific application needs, ensuring that the unique properties of aluminium oxide fully enhance the intended product functionality. In conclusion, aluminium oxide Al2O3 powder distinguishes itself through unmatched expertise, authoritativeness, and trustworthiness. This material continues to drive innovation across industries, grounded in real-world experience and rigorous scientific exploration. It is a testament to the possibilities afforded by advanced materials science, promising a robust future for a wide array of technological advancements.

Share

Next:

Latest news

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025

-

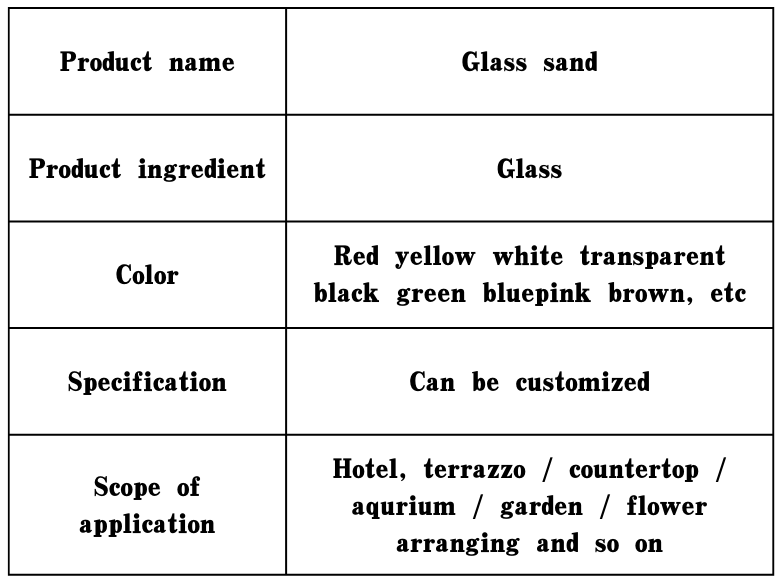

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025