Jan . 09, 2025 12:38

Back to list

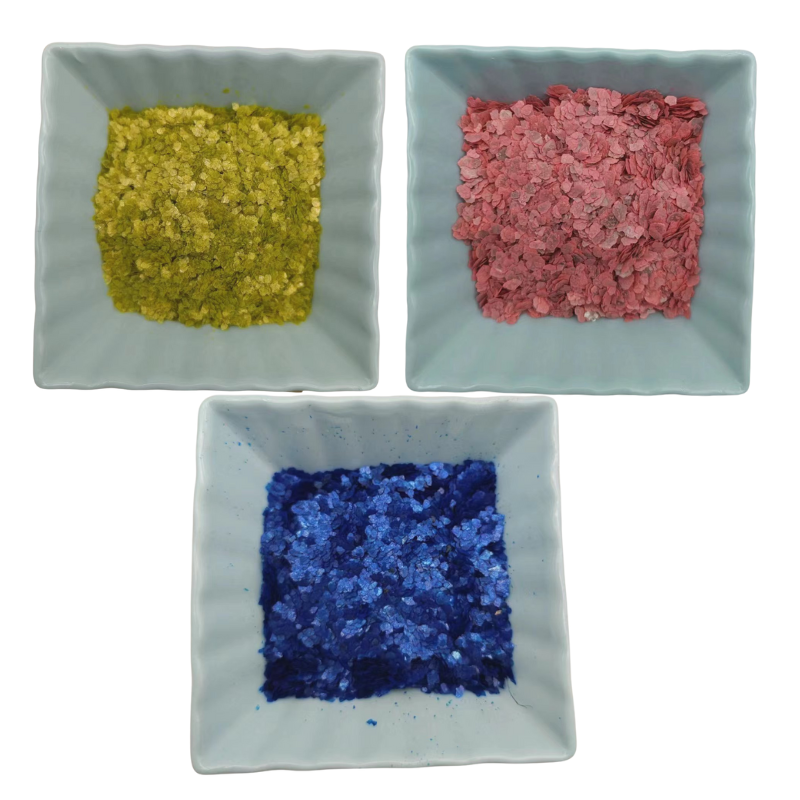

iron oxide colors

When you delve into the world of industrial materials, aluminium oxide emerges as a versatile and essential component, especially within the realm of advanced ceramics and abrasive technologies. As a seasoned expert in materials science and product development, the significance of aluminium oxide cannot be overstated, primarily due to its unique properties and myriad applications, each supported by empirical data and real-world usage experiences.

Experts within the coatings industry champion aluminium oxide for its protective qualities. The addition of aluminium oxide in paint formulations enhances scratch resistance and durability, attributes critical for automotive and aerospace applications. Engineers and manufacturers alike appreciate its role in extending the lifespan of components exposed to harsh environmental conditions, citing numerous case studies where treated surfaces exhibit superior wear resistance over extended periods. Trust in the use of aluminium oxide is further reinforced by its presence in the burgeoning field of renewable energy. As the global shift toward sustainable energy solutions accelerates, aluminium oxide plays a crucial role in the development of solid oxide fuel cells (SOFCs). Its high ionic conductivity and operational stability at elevated temperatures contribute to efficient energy conversion processes, a fact well documented in scientific literature and practical deployments. In summary, aluminium oxide's prominence across multiple industries is not mere happenstance but a testament to its unmatched properties, validated by rigorous testing and continuous innovation. Whether in everyday products or cutting-edge technologies, aluminium oxide underpins advancements that shape our modern world, proving that its value extends far beyond theoretical applications into tangible, impactful results.

Experts within the coatings industry champion aluminium oxide for its protective qualities. The addition of aluminium oxide in paint formulations enhances scratch resistance and durability, attributes critical for automotive and aerospace applications. Engineers and manufacturers alike appreciate its role in extending the lifespan of components exposed to harsh environmental conditions, citing numerous case studies where treated surfaces exhibit superior wear resistance over extended periods. Trust in the use of aluminium oxide is further reinforced by its presence in the burgeoning field of renewable energy. As the global shift toward sustainable energy solutions accelerates, aluminium oxide plays a crucial role in the development of solid oxide fuel cells (SOFCs). Its high ionic conductivity and operational stability at elevated temperatures contribute to efficient energy conversion processes, a fact well documented in scientific literature and practical deployments. In summary, aluminium oxide's prominence across multiple industries is not mere happenstance but a testament to its unmatched properties, validated by rigorous testing and continuous innovation. Whether in everyday products or cutting-edge technologies, aluminium oxide underpins advancements that shape our modern world, proving that its value extends far beyond theoretical applications into tangible, impactful results.

Share

Next:

Latest news

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025