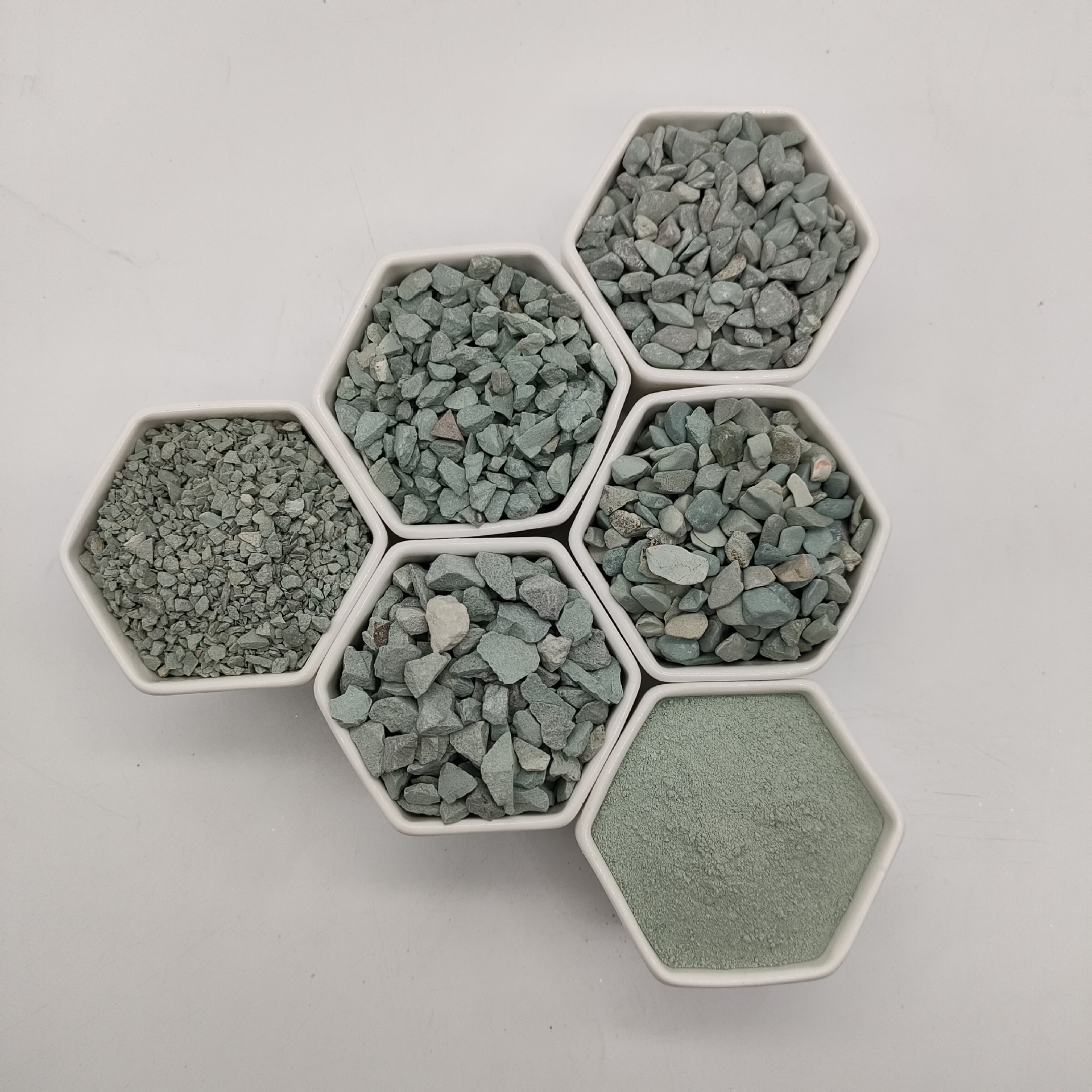

alumina aluminum oxide

Understanding Alumina The Foundation of Aluminum Oxide

Alumina, chemically known as aluminum oxide (Al2O3), is a crucial compound that plays a significant role in various industrial applications. It is a versatile material with unique properties that make it invaluable in fields ranging from metallurgy to ceramics and even electronics. The importance of alumina cannot be overstated, as it is both a precursor to aluminum production and a vital material in its own right.

What is Alumina?

Alumina is an inorganic compound formed by the reaction of aluminum with oxygen. It primarily exists in two forms α-alumina (corundum), which is the most stable and commonly employed variant, and β-alumina. Corundum is prized for its hardness and is often used in abrasive materials. The production of alumina typically involves refining bauxite ore, which is rich in aluminum compounds. The Bayer process, developed in the late 19th century, is the most widely used method for extracting alumina from bauxite.

Production Process

The Bayer process involves several critical steps. First, bauxite ore is crushed and washed to remove impurities. The ore is then treated with a hot concentrated solution of sodium hydroxide (NaOH). This alkali reacts with aluminum-bearing minerals in the bauxite, forming soluble sodium aluminate. The undissolved residue, primarily iron oxide and silica, is removed through sedimentation. Upon cooling, the sodium aluminate solution is seeded with aluminum hydroxide crystals, encouraging the precipitation of aluminum hydroxide. This precipitate is then filtered, washed, and subsequently heated to remove water, leading to the formation of alumina.

Applications of Alumina

1. Aluminum Production The most significant application of alumina is in the production of aluminum metal. Through the Hall-Héroult process, alumina is subjected to electrolysis in molten cryolite, resulting in the extraction of pure aluminum. This metal is essential for numerous industries due to its lightweight, strength, and corrosion resistance.

2. Abrasives α-Alumina is one of the hardest substances known, making it ideal for manufacturing abrasive materials. It is widely used in grinding wheels, sandpapers, and various polishing compounds. The durability and sharpness of alumina particles contribute to their efficacy in these applications.

alumina aluminum oxide

3. Ceramics Alumina is a critical component in advanced ceramics, providing hardness and thermal stability. High-purity alumina ceramics are used in applications such as insulators, electrical components, and dental materials. Its resistance to wear and high temperatures makes it suitable for harsh environments.

4. Catalysts and Catalyst Supports In the chemical industry, alumina serves as a catalyst or a catalyst support in various reactions. Its high surface area and thermal stability make it an excellent medium for promoting chemical reactions, including in petrochemical processes and environmental applications.

5. Biomedical Applications With its biocompatibility, alumina is increasingly being utilized in the medical field. It is employed in dental implants, prosthetics, and orthopedic applications. Its strength and wear resistance make it an ideal choice for materials that must endure significant mechanical stress in the human body.

Environmental Considerations

While alumina production is crucial for numerous applications, it is essential to consider the environmental impact of the processes involved. The Bayer process generates waste, primarily red mud, which can pose disposal and contamination challenges. Efforts are ongoing to develop more sustainable methods of alumina extraction and to recycle the waste products effectively.

Future Prospects

As industries continue to evolve, the demand for alumina is expected to grow. Innovations in the production processes and applications of alumina will be pivotal in addressing environmental concerns while meeting the needs of a technological society. Research into alternative sources of alumina and improvements in the recycling of aluminum can contribute to a more sustainable future.

Conclusion

Alumina, or aluminum oxide, is a fundamental material with diverse applications that span various industries. Its unique properties, derived from its structure and production processes, make it an indispensable resource. As we move towards a more sustainable future, understanding and optimizing the use of alumina will be key in ensuring that we meet both industrial demands and environmental responsibilities. Whether in the form of ceramics, abrasives, or precursor material for aluminum, alumina will undoubtedly continue to play a crucial role in advancing technology and industry.

Share

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025