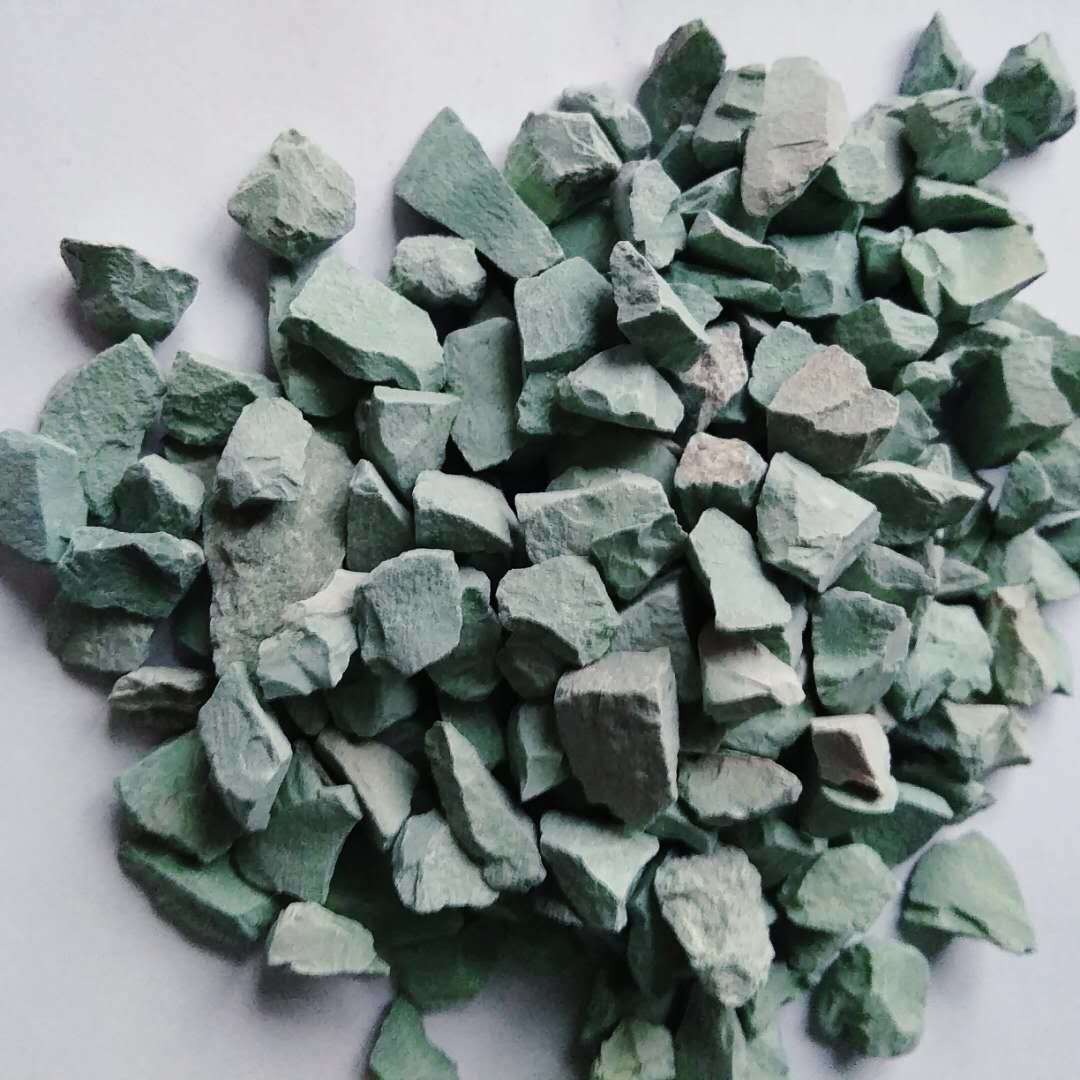

400 grit silicon carbide powder

The Versatility and Applications of 400 Grit Silicon Carbide Powder

Silicon carbide (SiC) powder is renowned for its superior hardness and thermal stability, making it an invaluable material across various industries. In particular, 400 grit silicon carbide powder stands out for its unique characteristics and diverse applications, which we will explore in this article.

Silicon carbide is a compound made of silicon and carbon, and it is synthesized through a process known as the Acheson process. This method involves heating a mixture of silicon dioxide and carbon in an electric furnace at high temperatures. The resulting crystalline material is then crushed and graded into different particle sizes, with 400 grit indicating a medium-coarse size that is particularly effective for a number of uses.

One of the primary applications of 400 grit silicon carbide powder is in the manufacturing of abrasive products. Due to its hardness, SiC is ideal for cutting, grinding, and polishing a variety of materials. For instance, it is commonly used in bonded abrasives, such as grinding wheels and discs. These tools are essential in metalworking, woodworking, and even in the production of ceramics, where precision and surface finish are critical.

In addition to its abrasive properties, 400 grit silicon carbide powder is also employed in the production of composite materials. When mixed with resins and polymers, SiC can enhance the material's mechanical strength, thermal conductivity, and wear resistance. This makes it suitable for applications in aerospace, automotive, and electrical industries, where components must withstand extreme conditions.

400 grit silicon carbide powder

Another significant application of 400 grit silicon carbide powder is found in the field of semiconductor manufacturing. Silicon carbide is increasingly being used in electronic components, particularly in high-power and high-temperature devices. The 400 grit size is often utilized during the polishing process of SiC substrates to achieve a smooth surface, which is vital for the performance of semiconductor devices. This application highlights the growing importance of silicon carbide in the context of modern electronics and energy efficiency.

Moreover, 400 grit silicon carbide powder can be used in water filtration systems. Its hardness and chemical stability allow it to function effectively as a filter medium, removing impurities from water without deteriorating. This application represents an environmentally friendly approach to water purification, aligning with the global push for sustainable practices.

In the realm of construction and masonry, 400 grit silicon carbide powder serves as a filler material in concrete and asphalt. Its properties enhance the durability and longevity of these materials, making them more resistant to wear and environmental damage. This application is especially relevant as urbanization increases the demand for robust construction materials that can withstand the test of time.

In conclusion, 400 grit silicon carbide powder is a remarkable material with a wide range of applications due to its exceptional hardness, thermal stability, and chemical inertness. From abrasives and composites to semiconductors and filtration systems, the versatility of SiC powder underscores its importance in modern technology and industrial processes. As demand continues to grow in various sectors, silicon carbide powder will undoubtedly play an essential role in the advancement of materials science and engineering.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025