OEM Manufacturer of Rutile and Anatase Titanium Dioxide in Bulk Supply

Titanium Dioxide Exploring OEM Manufacturers of Rutile and Anatase

Titanium dioxide (TiO2) has emerged as one of the most widely used white pigments in various industries, owing to its optimal brightness, high refractive index, and excellent durability. It exists primarily in three mineral forms rutile, anatase, and brookite, although brookite is less commonly utilized. Among these, rutile and anatase are the two main types relevant to manufacturers and consumers alike, each with unique properties and applications.

The Characteristics of Rutile and Anatase

Rutile, with a tetragonal structure, is known for its superior opacity and durability. It is primarily utilized in applications that require high performance, such as paints, coatings, plastics, and even in cosmetics. The rutile form of titanium dioxide is also favored in photovoltaic cells, contributing to advancements in solar energy technology.

Anatase, on the other hand, has a different tetragonal structure and is typically more reactive than rutile. This reactivity makes anatase an attractive option for applications in photocatalysis and environmental remediation. It is often used in self-cleaning surfaces, air purification, and in the manufacture of ultraviolet light-absorbing products. Additionally, anatase is more cost-effective than rutile, which can make it a preferred choice for certain applications.

The Role of OEM Manufacturers

The demand for high-quality titanium dioxide continues to grow, driven by advancements in various sectors including automotive, construction, and consumer goods

. Original Equipment Manufacturers (OEMs) play a crucial role in this market, providing specialized TiO2 products tailored to specific industry requirements. These manufacturers are tasked with optimizing production processes, ensuring that their products meet stringent quality standards while also being cost-effective.OEM manufacturers of titanium dioxide typically focus on providing either rutile or anatase forms, catering to specific client needs. For instance, companies seeking high-performance coatings may gravitate towards rutile TiO2 due to its superior properties, while those developing self-cleaning materials might prefer anatase for its photocatalytic abilities. Understanding the distinct characteristics of each form is essential for OEMs to develop and market their offerings effectively.

oem titanium dioxide rutile and anatase manufacturer

The Manufacturing Process

Producing high-quality titanium dioxide requires careful control of the manufacturing process. The two primary methods for TiO2 production are the sulfate process and the chloride process. The sulfate process, often employed for producing anatase, involves the digestion of ilmenite (iron titanium oxide) with sulfuric acid, resulting in the formation of titanium sulfate. In contrast, the chloride process, commonly used for rutile production, involves the chlorination of titanium-bearing ores, followed by purification of the titanium tetrachloride produced.

Regardless of the method, maintaining a controlled and standardized production environment is key to ensuring consistent quality. OEM manufacturers often emphasize their adherence to international quality standards, such as ISO certifications, showcasing their commitment to excellence.

Market Trends and Innovations

The titanium dioxide market is influenced by various factors including regulatory changes, environmental concerns, and technological advancements. Recent innovations in TiO2 manufacturing, such as the development of eco-friendly production methods and enhancements in photocatalytic applications, are reshaping the landscape of the industry.

Furthermore, the growing trend towards sustainability is prompting manufacturers to focus on reducing waste and energy consumption in their production processes. Many OEMs are now investing in research and development to create more sustainable forms of titanium dioxide, aimed at meeting the demands of environmentally conscious consumers.

Conclusion

As the demand for titanium dioxide continues to rise, OEM manufacturers of rutile and anatase are positioned at the forefront of innovation in this essential industry. By understanding the unique properties of each form and adhering to rigorous manufacturing processes, these companies are able to provide high-quality TiO2 products that cater to diverse applications. As technological advancements continue to evolve and environmental considerations become increasingly important, the role of OEMs in ensuring the availability of titanium dioxide in the market will only grow more prominent, driving further innovation and sustainability in the sector.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

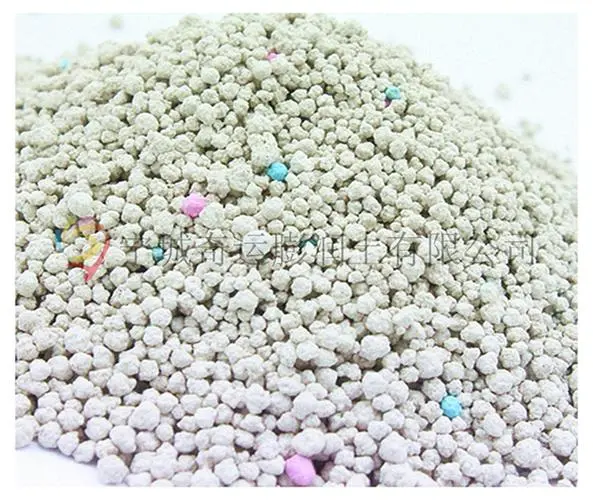

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025