OEM Manufacturers of Fly Ash Concrete Block Solutions for Sustainable Construction

The Role of OEM Fly Ash in Concrete Block Manufacturing

In recent years, the construction industry has been increasingly focused on sustainability and reducing its environmental impact. One innovative solution that has gained traction is the use of fly ash in concrete block manufacturing. Many manufacturers are now adopting Original Equipment Manufacturer (OEM) fly ash to enhance the quality of their concrete products while also contributing to eco-friendly practices.

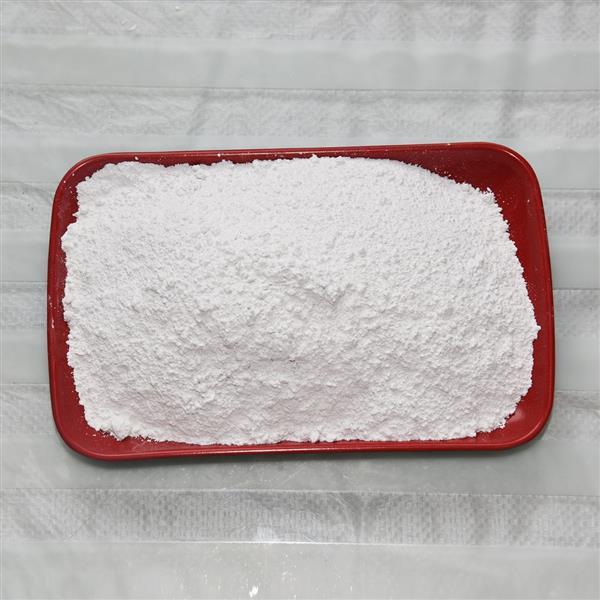

What is Fly Ash?

Fly ash is a fine powder that is a byproduct of burning pulverized coal in electric power plants. This material is collected from the flue gases by pollution control devices and has been recognized for its pozzolanic properties, making it an excellent additive to cement and concrete. By replacing a portion of cement with fly ash, manufacturers can reduce the overall carbon footprint of their products.

Advantages of Using Fly Ash in Concrete Blocks

1. Improved Workability and Durability The incorporation of fly ash in concrete blocks leads to improved workability. It allows for easier mixing, transportation, and placement of concrete. Additionally, fly ash enhances the durability of concrete by reducing permeability and increasing resistance to sulfate attack and other environmental factors.

2. Sustainability Utilizing OEM fly ash in concrete blocks helps to promote sustainability within the construction industry. This practice reduces the demand for Portland cement, which is associated with high levels of carbon dioxide emissions during its production. By substituting a percentage of cement with fly ash, manufacturers can significantly lower their carbon footprint.

oem fly ash in concrete blocks manufacturers

3. Cost-Effectiveness Fly ash is often less expensive compared to traditional cement. This cost-effectiveness translates to savings for manufacturers and customers alike. By using fly ash, manufacturers can maintain competitive pricing while providing high-quality concrete blocks.

4. Lightweight Construction Concrete blocks made with fly ash are often lighter than those made with traditional aggregates. This characteristic can lead to easier handling and reduced transportation costs, making it an attractive option for builders and contractors.

The Role of OEM Manufacturers

Original Equipment Manufacturers (OEM) play a crucial role in the integration of fly ash into concrete block production. They provide the specialized machinery and equipment required for efficient mixing and processing of fly ash. These OEM suppliers are essential for ensuring that the fly ash is properly incorporated into the concrete mixture, meeting the required standards for strength and durability.

Moreover, OEM manufacturers are also pivotal in advocating for the use of fly ash by educating potential users about its benefits. They often collaborate with construction firms and concrete producers to promote best practices in using fly ash, ensuring that the final products meet or exceed industry standards.

Conclusion

The adoption of OEM fly ash in concrete block manufacturing is a significant step towards more sustainable construction practices. With its myriad benefits—ranging from enhanced durability and workability to cost savings and reduced environmental impact—fly ash is becoming a vital component of modern concrete production. As the construction industry continues to evolve, the collaboration between OEM manufacturers and concrete producers will be essential in driving innovation and promoting greener building practices. By prioritizing the use of materials like fly ash, we can pave the way for a more sustainable and eco-friendly future in construction.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025