OEM Fly Ash and Silica Fume Production Facility for Enhanced Concrete Solutions

The Role of OEM Fly Ash and Silica Fume Factories in Construction Material Production

In the modern construction industry, the utilization of advanced materials has been pivotal in enhancing the durability and sustainability of infrastructure. Among these materials, fly ash and silica fume have emerged as crucial components, especially when sourced from Original Equipment Manufacturers (OEMs). The role of OEM fly ash and silica fume factories is crucial not only in the production of high-quality construction materials but also in addressing environmental concerns associated with conventional cement use.

Understanding Fly Ash and Silica Fume

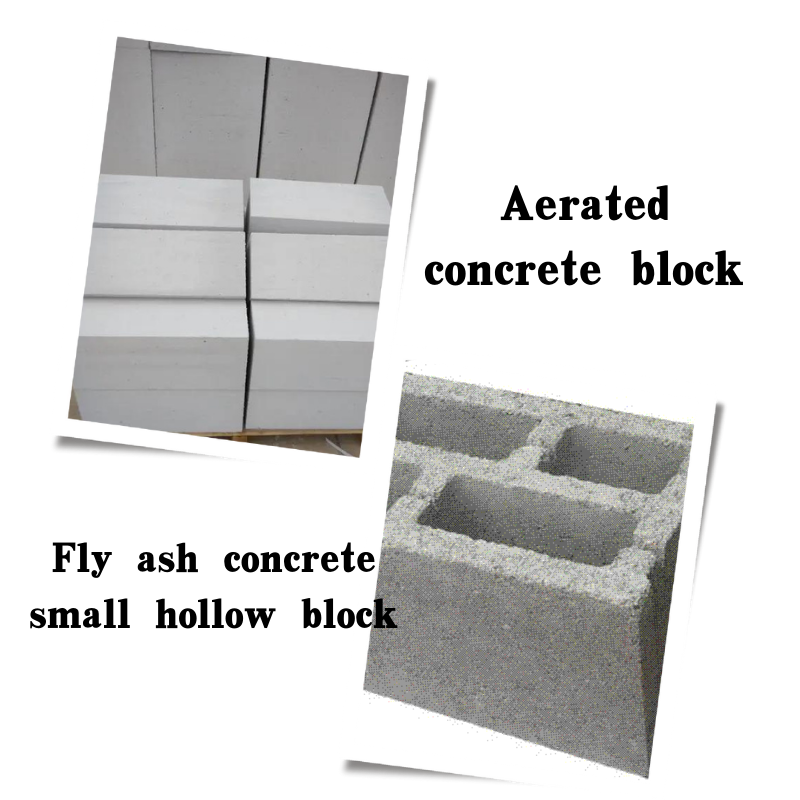

Fly ash is a byproduct of burning pulverized coal in electric power generating plants. It is a fine powder that can significantly improve the workability and strength of concrete while reducing the water demand. Silica fume, on the other hand, is a byproduct of producing silicon metal or ferrosilicon alloys. It consists primarily of silicon dioxide and is known for its pozzolanic properties that enhance the mechanical properties of concrete. Both materials are utilized to replace a portion of Portland cement in concrete mixtures, resulting in a more environmentally friendly and economically viable construction material.

The Importance of OEMs in Material Quality

Original Equipment Manufacturers (OEMs) play a significant role in ensuring the quality and consistency of fly ash and silica fume. These manufacturers adhere to stringent quality control measures throughout the production process. By sourcing materials from reliable OEMs, construction firms can guarantee that the fly ash and silica fume used in their projects meet specific industry standards and regulations. This consistency is vital in guaranteeing the durability and performance of concrete in various environmental conditions.

Environmental Benefits

The use of fly ash and silica fume from OEM factories significantly contributes to sustainable construction practices. The production of conventional Portland cement is energy-intensive, resulting in substantial carbon dioxide emissions. By replacing a portion of cement with fly ash and silica fume, the carbon footprint of concrete can be drastically reduced. Furthermore, utilizing industrial byproducts helps in waste management, as these materials would otherwise contribute to landfill issues. OEM factories that produce these supplementary cementitious materials adhere to environmentally friendly practices, further supporting the push for sustainability in construction.

oem fly ash and silica fume factory

Innovations in Production Techniques

OEM fly ash and silica fume factories are embracing modern technologies to enhance production efficiency. Innovations such as automated mixing and advanced quality testing equipment ensure a uniform and high-quality product. Additionally, these factories are exploring techniques to improve the performance characteristics of both fly ash and silica fume. For instance, the optimization of particle size distribution and chemical composition can lead to even greater improvements in the concrete's final properties.

Applications in Construction

The integration of fly ash and silica fume in concrete mixes opens up numerous possibilities in construction applications. Structures that demand high-performance characteristics, such as bridges, high-rise buildings, and industrial floors, benefit significantly from the use of these materials. They not only enhance the mechanical properties of concrete but also improve resistance to aggressive environmental factors, such as sulfate attack and alkali-silica reaction, thus prolonging the lifespan of structures.

Furthermore, the use of fly ash and silica fume allows for the creation of lightweight concrete, which can decrease the overall structural load and, consequently, reduce material usage. This innovation in structural design aligns with sustainability goals while also offering cost savings in construction projects through reduced material consumption and lower transportation costs.

Conclusion

The significance of OEM fly ash and silica fume factories cannot be overstated in today's construction landscape. By providing high-quality, sustainable alternatives to traditional cement, these manufacturers contribute to environmentally responsible building practices while ensuring the longevity and durability of concrete structures. As the industry continues to evolve, the collaboration between OEMs, regulatory bodies, and construction firms will be essential in promoting innovative solutions that harmonize construction efficiency with environmental stewardship. Embracing these advancements not only enhances the quality of construction materials but also paves the way for a more sustainable future in the building industry.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025