Sepiolite Powder Production Facilities and Their Applications in Various Industries

Sepiolite Powder Factories An Overview

Sepiolite, a unique magnesium silicate mineral, is known for its fibrous structure and high absorptive properties. It has a wide range of applications, including in the production of animal feed, the manufacturing of paints and coatings, and as an additive in various industrial processes. The growing demand for sepiolite powder has led to the establishment of specialized factories focused on its processing and distribution. This article explores the significance of sepiolite powder factories, their processes, and the impact of this mineral on various industries.

The Significance of Sepiolite Powder

Sepiolite is characterized by its lightweight and porous nature, which allows it to absorb oils, chemicals, and moisture effectively. This property makes it a valuable ingredient in the production of cleaning products, litter materials, and as a filler in plastics and rubber. The agricultural sector also benefits from sepiolite powder, as it can be used to enhance soil quality and improve plant growth.

The mineral's versatility has led to an increasing market for its usage. Consequently, the demand for high-quality sepiolite powder has driven the establishment of dedicated factories that focus on the extraction and processing of this mineral.

Production Process in Sepiolite Powder Factories

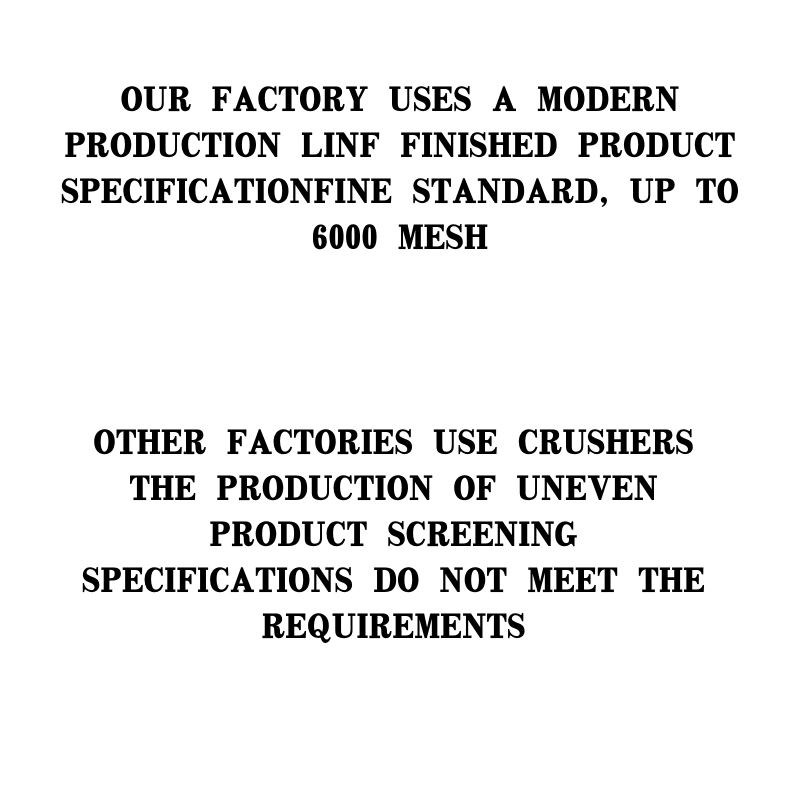

The production of sepiolite powder typically involves several key steps mining, crushing, milling, and quality control. The process begins with the extraction of raw sepiolite from mines. After mining, the raw material undergoes initial crushing to break it into manageable sizes.

The next stage involves milling, where the crushed sepiolite is processed into a fine powder. Factories often utilize specialized grinding equipment to achieve the desired particle size and purity. Depending on the intended application, the powder may be treated or modified to enhance its characteristics, such as increasing its surface area or improving its binding properties.

Quality control is an essential part of the production process. Factories employ stringent testing methods to ensure that the sepiolite powder meets industry standards and customer specifications. This may include analyzing the mineral composition, particle size distribution, and moisture content.

sepiolite powder factories

Environmental Considerations

While sepiolite powder factories contribute significantly to various industries, they must also consider environmental sustainability. Mining and processing operations can have adverse effects on local ecosystems if not managed responsibly. Hence, many factories adopt eco-friendly practices, including effective waste management, minimization of dust emissions, and water conservation strategies.

Furthermore, companies are increasingly exploring the use of renewable energy sources to power their operations, reducing their carbon footprint. By adopting such practices, sepiolite powder factories can balance production efficiency with environmental responsibility, thereby promoting sustainable development.

Market Trends and Future Prospects

The market for sepiolite powder is expected to grow due to its diverse applications across multiple industries. The increasing demand for environmentally friendly products and materials is driving innovation within the sector. As industries continue to seek natural alternatives to synthetic chemicals, the importance of sepiolite powder is likely to rise.

Moreover, advancements in processing techniques and technologies will enable factories to produce higher quality sepiolite powder more efficiently. This will not only enhance the competitive edge of manufacturers but also contribute to meeting the growing market demand.

Conclusion

Sepiolite powder factories play a crucial role in the supply chain of various industries, delivering a mineral that is both versatile and beneficial. As the demand for sepiolite continues to rise, these factories must navigate the challenges of production and environmental sustainability while also embracing technological advancements. With an eye toward the future, the sepiolite industry appears poised for growth, contributing to both economic development and the promotion of environmentally friendly practices in manufacturing. As such, the role of sepiolite powder factories will remain significant, positioning them as key players in the quest for sustainable industrial practices.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025