Custom Calcium Carbonate Powder Manufacturers for High-Quality Industrial Applications

The Importance of Custom Calcium Carbonate Powder in Modern Industries

Calcium carbonate (CaCO3) is a versatile compound that plays a crucial role in various industries, from construction and paper manufacturing to pharmaceuticals and food processing. With a diverse range of applications, the demand for custom calcium carbonate powder has been on the rise. This article explores the significance of custom calcium carbonate powder and why it has become a focal point for factories worldwide.

Understanding Calcium Carbonate

Calcium carbonate is a naturally occurring mineral that can be found in geological formations as sedimentary rock. It is typically extracted from limestone, marble, and chalk and is known for its excellent properties such as whiteness, particle size distribution, and chemical purity. These properties make it an essential ingredient in a multitude of products, including adhesives, coatings, plastics, rubber, and ceramics.

The Role of Customization

One of the key advantages of calcium carbonate powder is the ability to customize its properties according to specific industrial requirements. Custom calcium carbonate powder can be tailored in terms of particle size, morphology, surface treatment, and crystalline structure. This level of customization allows manufacturers to optimize their processes and products, enhancing performance and efficiency.

1. Particle Size The size of calcium carbonate particles can significantly affect the performance of end products. For example, in the paint and coatings industry, finer particles provide better coverage and gloss, while in the paper industry, coarser particles can improve bulk and opacity. Customization ensures that manufacturers can select the optimal particle size for their specific applications.

2. Surface Treatment Surface treatments can enhance the dispersibility and compatibility of calcium carbonate with other materials. For instance, treated powder can improve the performance of polymers and enhance the strength and durability of products. Factories can specify the type of surface treatment needed to achieve the desired performance enhancement.

3. Morphology and Structure The crystal structure of calcium carbonate (calcite, aragonite, or vaterite) also impacts its behavior and application. Custom factories can produce specific morphologies that suit particular applications in various industries, from agriculture to cosmetics.

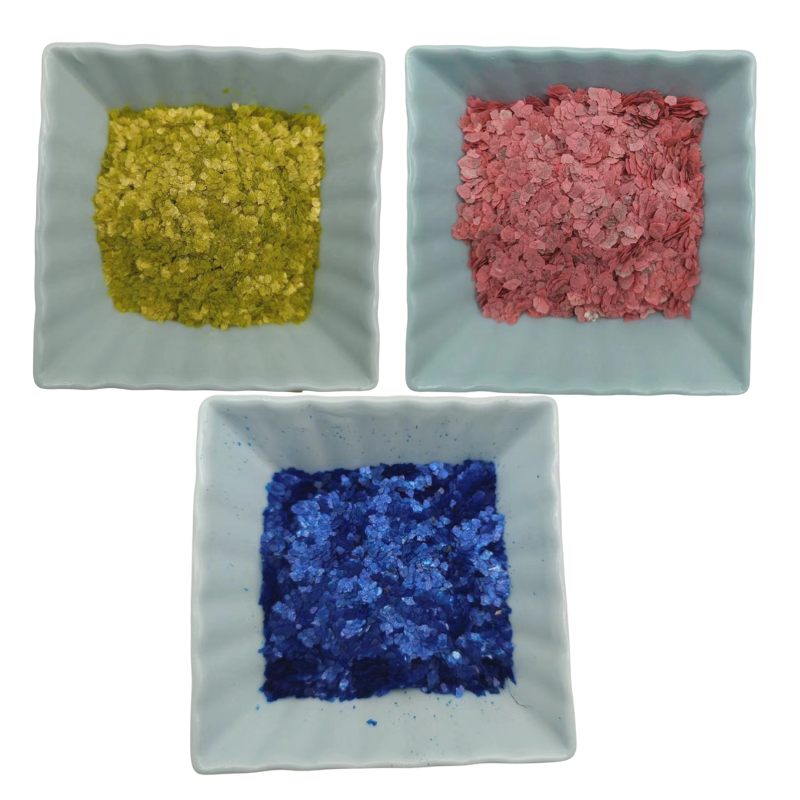

custom calcium carbonate powder caco3 factories

Industrial Applications

The versatility of custom calcium carbonate powder extends to a wide range of industries

- Construction In the construction sector, calcium carbonate is used as a filler in building materials and as a cement ingredient. Custom formulations can improve the workability and longevity of construction products.

- Paper and Plastics In paper production, CaCO3 serves as a brightening agent and filler, enhancing the sheet's opacity and brightness. In plastics, it acts as a filler that can reduce production costs while improving mechanical properties.

- Pharmaceuticals and Food In the pharmaceutical and food industries, calcium carbonate is used as a calcium supplement and an antacid. Custom formulations can ensure compliance with safety standards and enhance bioavailability.

- Agriculture Calcium carbonate plays a significant role in the agricultural sector as a soil conditioner and fertilizer. Custom formulations can help in enhancing soil quality and crop yield.

Conclusion

As industries continue to evolve, the demand for custom calcium carbonate powder is expected to increase. Factories specializing in producing this versatile compound are pivotal in meeting the diverse needs of various sectors. The ability to customize particle size, morphology, and surface treatment allows manufacturers to optimize their products, resulting in improved performance and efficiency.

In conclusion, investing in custom calcium carbonate powder can unlock significant benefits, fostering innovation and enhancing the quality of products across multiple industries. As we look toward the future, it is evident that calcium carbonate will continue to be a key player in advancing industrial applications while addressing the specific needs of modern manufacturing.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025