custom pumice or perlite factories

Custom Pumice or Perlite Factories Meeting Diverse Industry Needs

In today's rapidly evolving industrial landscape, the demand for specialized materials such as pumice and perlite is on the rise. These two naturally occurring volcanic materials offer a range of unique properties that make them invaluable across numerous sectors, including horticulture, construction, and filtration. As industries strive for enhanced performance, efficiency, and sustainability, custom pumice and perlite factories have emerged as crucial players in supplying tailored solutions to meet diverse needs.

Understanding Pumice and Perlite

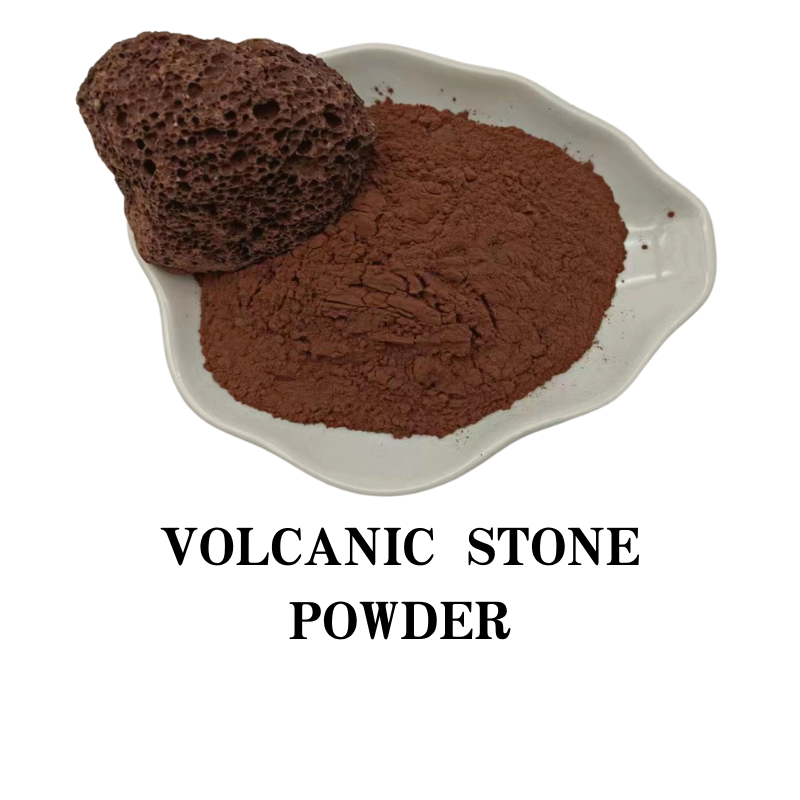

Before diving into the significance of custom factories, it's essential to understand what pumice and perlite are. Pumice is a light, porous volcanic rock formed during explosive volcanic eruptions when gas bubbles are trapped in the molten lava. This material is widely utilized in horticulture for its aeration properties, lightweight nature, and retention of water and nutrients.

Perlite, on the other hand, is a naturally occurring volcanic glass that expands when heated. Its unique properties make it an excellent insulator, lightweight filler, and soil amendment. Like pumice, perlite is often used in horticulture, construction, and various industrial applications, including insulation and filtration.

The Role of Custom Factories

Custom pumice and perlite factories play a pivotal role in addressing the diverse requirements of various industries. Unlike conventional manufacturing methods that produce standard materials, custom factories focus on creating tailor-made products based on specific customer needs. This is particularly important in fields where precision, performance, and sustainability are paramount.

custom pumice or perlite factories

1. Tailored Solutions One of the key advantages of custom factories is their ability to provide products that perfectly match client specifications. Clients can request variations in size, density, and other properties of pumice or perlite to suit their unique applications. This level of customization is crucial in horticulture, where different plants require specific soil compositions for optimal growth.

2. Enhanced Quality Control Custom factories often implement stringent quality control measures throughout the manufacturing process. With a focus on producing specialized materials, these factories can perform comprehensive testing to ensure that each batch meets the required standards. As a result, customers receive consistent, high-quality products that enhance their operational efficiency.

3. Sustainable Practices As environmental awareness grows, industries are increasingly seeking sustainable solutions. Custom pumice and perlite factories are uniquely positioned to adopt eco-friendly practices, such as using renewable energy sources, minimizing waste, and implementing recycling initiatives. By sourcing raw materials responsibly and maintaining sustainable manufacturing processes, these factories contribute to a greener future.

4. Innovation and Research The need for advanced materials is driving innovation in the pumice and perlite sectors. Custom factories often collaborate with researchers and industry experts to develop new formulations and applications. Whether it’s creating a lightweight aggregate for construction or a specialized soil mix for urban gardening, the pursuit of innovation is at the forefront of these operations.

5. Global Reach with Local Adaptation Custom factories are not limited by geographical boundaries. They can serve local markets while also catering to international clientele. Understanding the unique demands of different regions—such as varying climates and agricultural practices—enables these factories to adapt their products accordingly. This global reach ensures that diverse industries have access to high-quality pumice and perlite, regardless of location.

Conclusion

The emergence of custom pumice and perlite factories represents a significant evolution in how industries source and utilize these critical materials. By offering tailored solutions, maintaining stringent quality control, adopting sustainable practices, fostering innovation, and ensuring adaptability to various markets, these factories are poised to meet the growing demand for specialized volcanic materials. As industries continue to evolve and seek out efficient, environmentally friendly options, custom factories will undoubtedly play a crucial role in shaping the future of pumice and perlite applications across the globe. In this way, they contribute not only to individual business success but also to a more sustainable and efficient industrial ecosystem.

Share

-

Premium Metallic Mica Solutions Custom Factory & OEM ManufacturerNewsJul.05,2025

-

Premium Natural Zeolite Sand – Custom Manufacturers & Factories High Purity & Versatile UseNewsJul.04,2025

-

Premium Microsilica Silica Fume Powder Custom Manufacturers & Factories SolutionsNewsJul.04,2025

-

Premium Clay Pebbles for Drainage – China Manufacturer & OEM Factory SolutionsNewsJul.04,2025

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025