Custom Manufacturers for Cement and Fly Ash Solutions Tailored to Your Needs

The Rise of Custom Cement and Fly Ash Manufacturers

In recent years, the construction industry has been undergoing significant changes, propelled by the growing demand for sustainable building materials. Among these advancements, custom cement and fly ash manufacturers have emerged as key players, driving innovation while addressing environmental concerns. This article delves into the importance of these manufacturers, the benefits of custom cement and fly ash, and the future of the construction materials market.

Understanding Custom Cement and Fly Ash

Cement has long been a staple in the construction industry, serving as a primary binder in concrete. However, traditional cement production is associated with high carbon dioxide emissions and energy consumption. As a result, manufacturers have sought alternatives and supplements to enhance the sustainability of cement.

Fly ash, a byproduct of coal combustion in power plants, has gained significant attention as a supplementary cementitious material. When used in concrete, fly ash enhances workability, durability, and strength while reducing the carbon footprint of construction projects. Custom cement, on the other hand, refers to tailored formulations that meet specific requirements of various construction projects, accommodating factors such as climate, structural demands, and desired performance characteristics.

The Role of Custom Manufacturers

Custom cement and fly ash manufacturers play an essential role in promoting green building practices. By leveraging advanced technology and research, these manufacturers offer tailored solutions that not only meet regulatory standards but also fulfill the specific needs of their clients.

1. Sustainability The growing emphasis on sustainable construction practices has led manufacturers to explore alternative raw materials and innovative production methods. Custom cement manufacturers often incorporate high volumes of fly ash, recycled aggregates, and other waste materials into their mixes, reducing reliance on virgin materials and minimizing environmental impact.

2. Performance Enhancement The ability to customize cement formulations allows manufacturers to enhance the performance characteristics of concrete. For instance, by adjusting the composition of fly ash, manufacturers can produce cement that performs better in aggressive environments, resist chemicals, or provide longevity in coastal areas. This ensures that the final product is not only environmentally friendly but also meets the specific performance criteria of construction projects.

custom cement and fly ash manufacturers

3. Cost-Effectiveness Custom solutions can also lead to cost savings. By optimizing material usage and reducing waste, manufacturers help clients to lower their overall project costs. Furthermore, the incorporation of fly ash and other industrial byproducts can be more economical than using traditional materials, thus offering a financially viable option for contractors and builders.

Challenges and Innovations

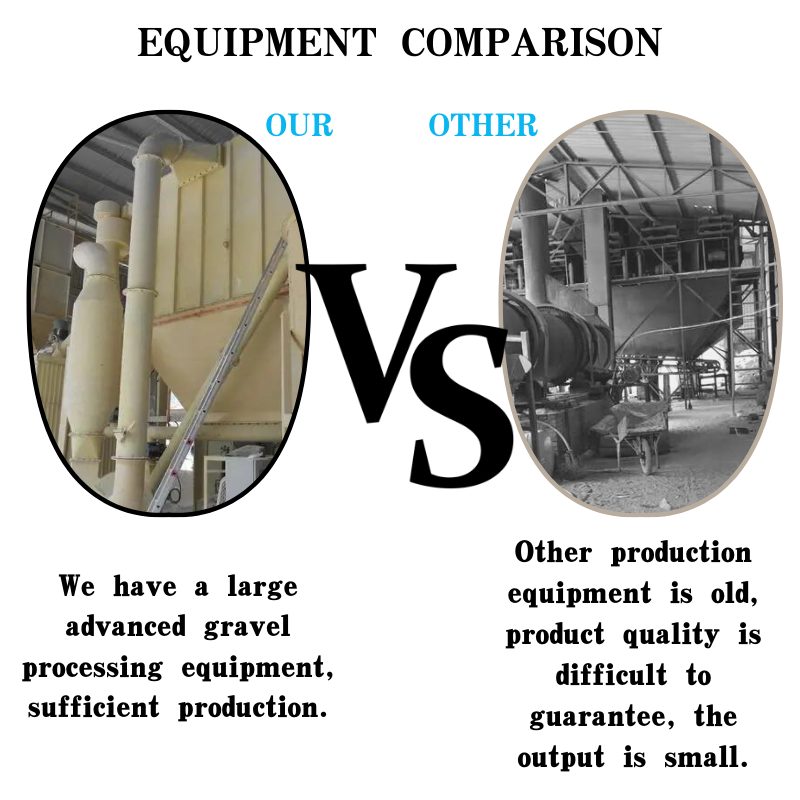

Despite the benefits, the custom cement and fly ash manufacturing industry faces several challenges. Quality control is paramount, as variations in source materials can affect the consistency and strength of the final products. Manufacturers must invest in robust testing and quality assurance protocols to guarantee the reliability of their custom mixes.

Moreover, the stigma associated with using byproducts like fly ash can hinder acceptance in certain markets. Education and outreach efforts are crucial to inform stakeholders about the advantages of using recycled materials in construction. Collaborative initiatives among industry players can lead to increased awareness and an eventual shift in public perception.

The Future of Custom Cement and Fly Ash Manufacturers

Looking ahead, the future appears promising for custom cement and fly ash manufacturers. Government regulations aiming to reduce carbon emissions are likely to continue driving demand for sustainable materials. As the construction industry embraces innovation, manufacturers are expected to invest more in research and development, exploring new materials and technologies that generate even more eco-friendly solutions.

Additionally, digital tools and automation can streamline production processes and enhance the precision of custom formulations. By harnessing data analytics, manufacturers can optimize their supply chains, predict demand, and improve product delivery times.

In conclusion, custom cement and fly ash manufacturers are at the forefront of the shift towards more sustainable construction practices. Their ability to tailor products to meet specific project demands while promoting environmental responsibility positions them as indispensable assets in the modern construction landscape. As the industry evolves, collaboration between manufacturers, contractors, and regulatory bodies will be vital to unlocking the full potential of these innovative materials, shaping a greener and more sustainable future for the built environment.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025