China's Use of Silica Fume in Concrete Mix Production for Enhanced Strength and Durability

The Role of Silica Fume in Concrete Mix A Focus on China

In the realm of construction materials, silica fume has emerged as a significant component that enhances the performance of concrete mixes. Particularly in China, where rapid urbanization and infrastructure development are the norms, the utilization of silica fume in concrete mix factories has seen a remarkable increase. This article explores the characteristics of silica fume, its benefits when incorporated into concrete, and its implications for the construction industry in China.

What is Silica Fume?

Silica fume is a byproduct of the silicon and ferrosilicon alloy production process. It consists of ultra-fine particles, primarily composed of silicon dioxide (SiO2). Due to its very small particle size, which is about 100 times finer than cement, silica fume possesses unique properties that make it ideal for enhancing the properties of concrete. When used in concrete, silica fume acts as a pozzolan, meaning it reacts with calcium hydroxide in the presence of water to form additional cementitious compounds, thereby improving strength and durability.

Advantages of Silica Fume in Concrete

1. Enhanced Strength and Durability One of the primary reasons for incorporating silica fume into concrete is its ability to substantially increase compressive strength. Concrete mixtures with silica fume often exhibit higher strength both in short-term and long-term scenarios. Furthermore, it improves the durability of concrete by reducing its permeability, which protects the structure from corrosive elements.

2. Improved Workability Silica fume can improve the workability of concrete mixtures. Despite its fine nature, when properly incorporated, it allows for the production of highly workable concrete that is easier to place and finish. This characteristic is critical in complex construction scenarios where ease of handling is vital.

3. Reduced Shrinkage Concrete with silica fume typically exhibits lower shrinkage, which is beneficial in minimizing cracking and ultimately enhances the lifespan of concrete structures. This is particularly important in large-volume pours where shrinkage can lead to significant structural issues.

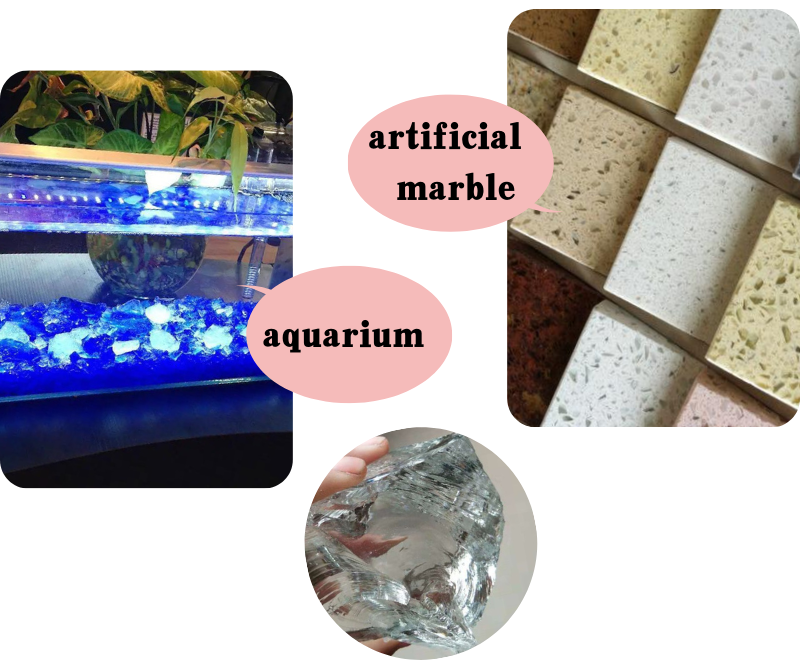

china silica fume in concrete mix factory

4. Sustainability The use of silica fume not only enhances concrete performance but also aligns with the growing emphasis on sustainable construction practices. By utilizing industrial waste products, the concrete industry can reduce its reliance on virgin materials, thereby minimizing its environmental footprint.

The Impact in China

As one of the largest producers and consumers of concrete, China has been at the forefront of embracing silica fume technology. With the booming construction sector, the demand for high-performance concrete is ever-increasing. This has led to the proliferation of concrete mix factories that incorporate silica fume to meet stringent building codes and performance specifications.

Chinese regulations have increasingly favored the use of advanced materials in construction, spurring factories to adopt silica fume in their mixes. Various infrastructure projects, ranging from bridges and highways to high-rise buildings, have benefited from the incorporation of silica fume, showcasing improved performance in terms of load-bearing capacity and resistance to environmental factors.

Challenges and Considerations

However, the adoption of silica fume is not without its challenges. The handling of silica fume requires specialized knowledge due to its fine nature, which can create health hazards if inhaled. Additionally, the cost of silica fume can be higher compared to traditional materials, presenting economic considerations for contractors and developers. It is crucial for mix design to be carried out meticulously to ensure optimal performance and cost-efficiency while taking advantage of silica fume's properties.

Conclusion

In conclusion, silica fume plays a transformative role in enhancing the properties of concrete mixes, particularly within the rapidly evolving construction landscape in China. Its benefits, including increased strength, durability, and sustainability, make it a valuable material for modern concrete technology. As the construction industry continues to grow, the careful application of silica fume in concrete mix factories will undoubtedly pave the way for innovative and resilient structures that can stand the test of time.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025