Custom Barite Powder for Drilling Fluids in Oil and Gas Industry Applications

OEM Barite Powder for Mud Drilling A Comprehensive Overview

Barite, a mineral composed of barium sulfate (BaSO4), plays a crucial role in the drilling industry, particularly in the oil and gas sector. It is a dense, inert material that is commonly used as a weighting agent in drilling fluids, which are essential for maintaining pressure in the borehole and preventing blowouts. With the increased demand for efficient drilling operations, OEM (Original Equipment Manufacturer) barite powder has garnered significant attention for its quality and performance. In this article, we will explore the importance of OEM barite powder for mud drilling, its benefits, and key considerations for businesses looking to procure it.

Significance of Barite in Mud Drilling

Mud drilling, or drilling with a fluid medium, utilizes various substances to create a slurry that facilitates the drilling process. Barite is added to these drilling muds to increase their density, which provides sufficient hydrostatic pressure to counteract the natural pressure encountered in geological formations. This is particularly important in preventing fluid influx and ensuring the stability of the borehole.

The use of high-quality barite powder in drilling muds directly impacts the efficiency and safety of drilling operations. OEM barite powder, specifically, refers to barite that is manufactured under strict quality control standards to meet the specifications of original equipment manufacturers. This ensures that the product is consistent in composition, finely ground, and appropriately sized for optimal performance in drilling applications.

Benefits of Using OEM Barite Powder

1. Consistency and Quality One of the primary advantages of OEM barite powder is its consistency. When sourced from reputable manufacturers, the barite's chemical and physical properties are uniform, leading to more predictable performance in drilling applications. This consistency minimizes the risk of unexpected issues during drilling.

2. Improved Drilling Performance High-quality barite powder enhances the performance of drilling muds. Its high density effectively increases mud weight, which helps maintain hydraulic equilibrium and control pressure fluctuations in the borehole. This, in turn, leads to smoother drilling operations and reduced wear on drilling equipment.

3. Enhanced Environmental Compliance As environmental regulations become stricter, using OEM barite powder can help companies comply with these regulations. Reputable manufacturers often implement eco-friendly practices in their extraction and processing methods, resulting in a product that is less harmful to the environment.

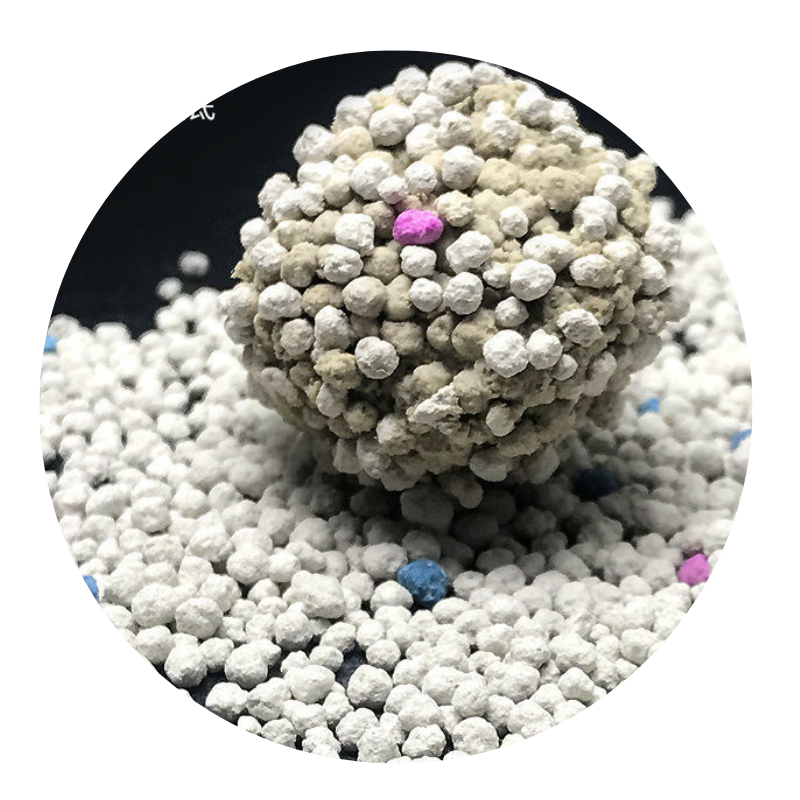

oem barite powder for mud drilling

4. Customization Options Many OEM suppliers offer customization options to meet specific project needs. This flexibility allows drilling companies to select barite powder that is tailored to their operational requirements, such as specific particle sizes or chemical additives that enhance performance.

Key Considerations When Sourcing OEM Barite Powder

When looking for OEM barite powder, companies should consider several factors

1. Supplier Reputation It is crucial to source barite from suppliers with a proven track record in the industry. Researching customer reviews, testimonials, and case studies can provide valuable insights into a supplier's reliability.

2. Certifications and Compliance Ensure that the supplier complies with industry standards and holds necessary certifications. This not only guarantees quality but also indicates a commitment to safety and environmental stewardship.

3. Supply Chain Logistics Evaluate the supplier's ability to meet delivery timelines and the efficiency of their supply chain. A reliable logistics process is essential for maintaining project timelines and operational efficiency.

4. Technical Support Partnering with a supplier that offers technical assistance can be beneficial. They can provide guidance on the optimal use of barite in drilling applications and help troubleshoot any issues that arise.

In conclusion, OEM barite powder is indispensable in mud drilling, offering various benefits that enhance drilling efficiency, safety, and environmental compliance. By selecting high-quality barite from reputable suppliers, businesses can ensure successful drilling operations and contribute to a more sustainable industry. Investing in OEM barite powder not only meets immediate operational goals but also supports long-term success in the competitive drilling market.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025