caco3 powder price factories

The Market Dynamics of Calcium Carbonate (CaCO3) Powder An In-Depth Analysis of Price Trends and Factory Production

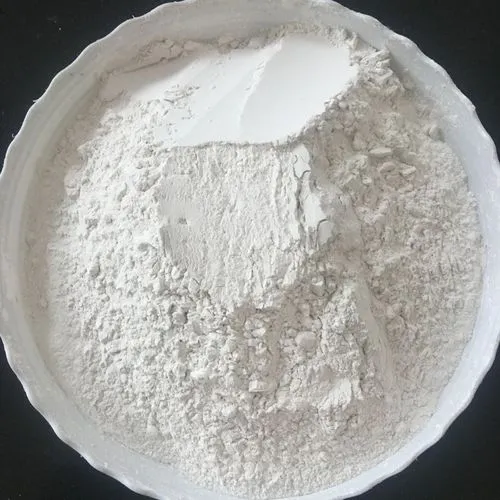

Calcium carbonate (CaCO3), a versatile compound found in rocks, shells, and the skeletons of marine organisms, has established itself as a foundational ingredient across various industries. Used primarily in construction, agriculture, pharmaceuticals, food products, and plastic manufacturing, the demand for CaCO3 powder continues to soar. This article delves into the price trends of CaCO3 powder, the factors influencing these prices, and the production capacities of factories worldwide.

Understanding Calcium Carbonate

Calcium carbonate comes in two main forms ground calcium carbonate (GCC) and precipitated calcium carbonate (PCC). GCC is produced through the crushing and grinding of natural limestone, while PCC is manufactured through a chemical process. Each type serves distinct purposes, with GCC primarily used in construction materials, and PCC being prominent in industries requiring high purity and fine particle size, such as food and pharmaceuticals.

Price Trends of CaCO3 Powder

As of 2023, the price of CaCO3 powder has experienced fluctuations influenced by various market forces. Typical prices for bulk GCC range from $30 to $150 per ton, depending on factors such as size, purity, and specific market segment. PCC, being a more refined version, can command higher prices, often exceeding $400 per ton.

Several factors play pivotal roles in shaping these prices

1. Raw Material Costs The price of limestone, the primary source of calcium carbonate, fluctuates based on mining regulations, regional supply constraints, and transportation costs. Higher extraction costs can lead to increased prices for the finished product.

2. Global Demand The construction and packaging industries contribute significantly to the demand for CaCO3. As infrastructural development accelerates globally, particularly in emerging economies, the need for CaCO3 increases, thereby exerting upward pressure on prices.

3. Technological Advancements Innovations in manufacturing processes can lead to more cost-effective production methods, impacting market prices. Factories investing in modern technology can produce higher quality CaCO3 at lower operational costs, which can stabilize or reduce market prices.

caco3 powder price factories

4. Environmental Regulations Stricter environmental standards for mining and processing operations can result in increased costs. Factories that are unable to comply may face penalties or operational restrictions, leading to reduced supply and potentially higher prices.

5. Geopolitical Factors Political instability in key producing regions can disrupt supply chains, affecting pricing. Tariffs or trade barriers can also impact the import and export of calcium carbonate, further influencing market dynamics.

Factory Production Capacities

The production capacity of CaCO3 powder factories varies significantly across the globe. Major producers include countries such as China, the United States, India, and Germany. Chinese factories dominate the market, largely due to the availability of raw limestone and lower labor costs. They produce a substantial portion of the world’s GCC and PCC, catering to both domestic and international markets.

In the United States, several large-scale operations focus on high-quality PCC production, catering to specific applications in the food and pharmaceutical sectors. With increasing health regulations, U.S.-based factories are investing in compliance and quality assurance to sustain their market share.

Indian factories are rapidly expanding, fueled by domestic demand in sectors like construction and plastics. The government's push for infrastructure development has significantly boosted the local market for CaCO3, prompting factories to upscale production.

Conclusion

The market for calcium carbonate powder is complex and ever-evolving. Prices are determined not only by local and global demand but also by operational costs, technological innovations, and regulatory landscape. As industries continue to grow, particularly construction and packaging, the demand for both GCC and PCC is expected to increase, potentially leading to further price fluctuations.

Factories across various regions are adapting to these market changes by enhancing production capacities and improving efficiency. As we look to the future, the interplay between supply and demand, along with external factors like geopolitical stability and environmental regulations, will continue to shape the landscape of the calcium carbonate powder market.

In summary, understanding the myriad factors influencing CaCO3 powder prices and the dynamics of production factories is essential for stakeholders across industries. This knowledge can guide strategic decisions in procurement, investment, and market positioning, ensuring companies remain competitive in an increasingly challenging environment.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025