Exploring the Properties and Applications of Alumina in Modern Industries

Understanding Alumina (Al₂O₃) Properties, Applications, and Innovations

Alumina, chemically represented as Al₂O₃, is a compound derived from aluminum. It is a white, odorless, and hard crystalline substance that serves as a critical material in various industries. As one of the primary components of bauxite, which is the principal ore of aluminum, alumina plays a pivotal role in the production and processing of aluminum metal. Beyond its industrial significance, alumina possesses unique properties that make it valuable in numerous applications ranging from ceramics to catalysts.

Properties of Alumina

Alumina exhibits remarkable physical and chemical properties that contribute to its widespread usage. One of its most notable characteristics is its high melting point, which is approximately 2,072 degrees Celsius (3,762 degrees Fahrenheit). This feature makes it ideal for high-temperature applications, including the manufacturing of refractory materials that must withstand extreme conditions without melting or degrading.

Additionally, alumina is known for its excellent hardness and abrasion resistance, ranking high on the Mohs scale. This hardness enables it to be utilized as an abrasive in grinding and polishing applications, making it an essential ingredient in the production of sandpapers and grinding wheels.

Alumina is also electrically insulating, which makes it suitable for electrical applications where conductivity is not desired. Its chemical inertness contributes to its stability under various environments, ensuring that it does not react with most acids or alkalis, making it a reliable material for numerous chemical processes.

Applications of Alumina

The applications of alumina are extensive and diverse. In the aluminum industry, it serves as the primary feedstock for producing aluminum metal. The Bayer process, which extracts alumina from bauxite ore, is a fundamental process in the aluminum refining industry. Once extracted, alumina is subjected to electrolysis to produce aluminum.

alumina ai203

In the field of ceramics, alumina is utilized to produce advanced ceramic materials that are used in various applications, including dental restorations, cutting tools, and electronic insulators. The ability to engineer alumina into fine powders allows for its use in creating bio-ceramics, which are essential in medical implants and prosthetics.

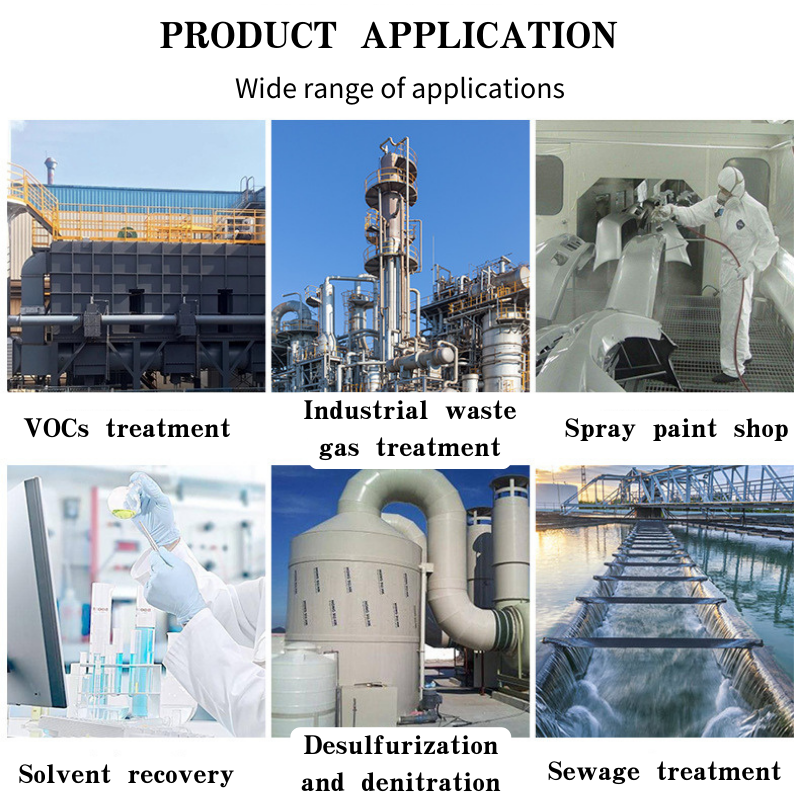

Alumina is also essential in the production of catalysts used in the petrochemical industry. Its high surface area and porous nature make it an effective medium for catalytic reactions, allowing for the efficient conversion of raw materials into valuable products. Moreover, gamma-alumina, a specific form of alumina, is used as an adsorbent for various filtration applications.

Innovations in Alumina Technology

With advancements in technology and materials science, researchers are continually exploring new applications and enhancements for alumina. Recent developments include the fabrication of nanostructured alumina, which exhibits unique properties that differ significantly from its bulk counterparts. Nano-alumina is being studied for its potential use in drug delivery systems, where its high surface area and biocompatibility can facilitate the targeted delivery of therapeutic agents.

Additionally, the integration of alumina into composite materials is gaining traction, as it enhances mechanical strength, thermal stability, and resistance to wear. Such composites are being developed for applications in aerospace, automotive, and sporting goods industries.

Furthermore, as the world is becoming increasingly focused on sustainability and environmentally friendly practices, alumina is being explored for its role in capturing carbon dioxide. Alumina can be utilized in the development of sorbents that help mitigate greenhouse gas emissions from industrial processes.

Conclusion

Alumina (Al₂O₃) is a versatile and vital material that underpins many industries through its unique properties and diverse applications. From aluminum production to advanced ceramics and catalysis, its importance cannot be overstated. As innovations continue to emerge, the potential for alumina to contribute to future technological advancements and sustainable practices appears promising. With its robust nature and adaptability, alumina remains a cornerstone of material science and engineering, shaping the future of numerous critical sectors. Whether through traditional applications or groundbreaking innovations, the journey of alumina is far from over.

Share

-

Custom & Bulk Zeolite Powder Manufacturer High-Purity SolutionsNewsMay.08,2025

-

Custom Bronze Mica Powder Premium Quality & Bulk OrdersNewsMay.08,2025

-

Custom Granite Pebbles Manufacturers Durable & Natural DesignsNewsMay.07,2025

-

Custom Perlite for Orchids Lightweight, pH-Neutral Mix FactoriesNewsMay.07,2025

-

Custom Raw Vermiculite Manufacturers & Factories Bulk OrdersNewsMay.07,2025

-

Custom Rainbow Pebbles Manufacturers High-Quality & DurableNewsMay.07,2025