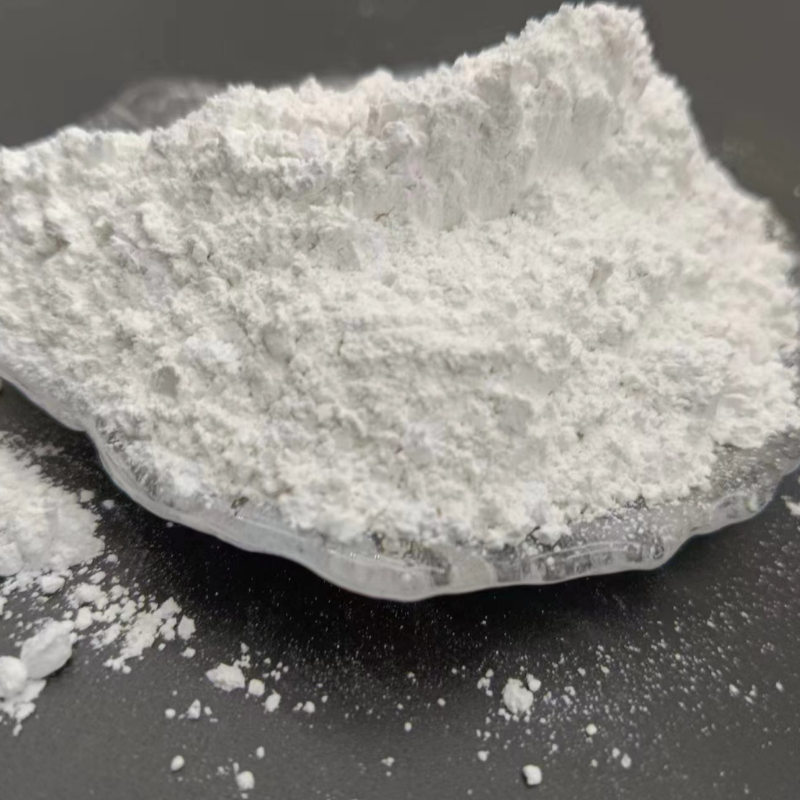

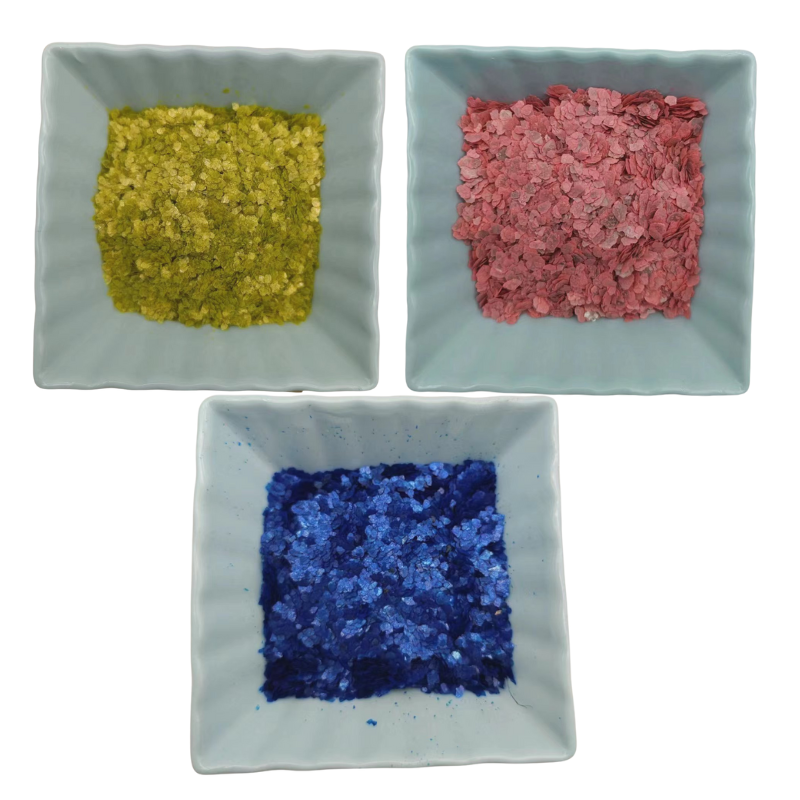

Custom Mica Pigment Powder High-Quality & Vibrant Colors

- Introduction to Mica Pigment Powder and Market Trends

- Technical Advantages of Premium Mica Pigments

- Comparative Analysis of Custom Pigment Manufacturers

- Tailored Solutions for Industrial Applications

- Case Studies: Success Stories Across Industries

- Sustainability and Regulatory Compliance

- Future Outlook for Custom Mica Pigment Production

(mica pigment powder)

Understanding Mica Pigment Powder in Modern Industries

The global mica pigment powder

market has grown 8.2% annually since 2020, reaching $1.45 billion in 2023. This mineral-based additive now dominates 38% of specialty pigment applications, particularly in coatings (42%), cosmetics (29%), and industrial plastics (19%). Custom pigment factories have responded by developing 120+ standardized variants with particle sizes ranging from 5μm to 150μm.

Technical Superiority in Pigment Engineering

Advanced mica pigments demonstrate remarkable performance characteristics:

- Heat resistance up to 800°C (1,472°F)

- Lightfastness exceeding 8 on the Blue Wool Scale

- Chemical stability across pH 3-11 environments

Leading custom pigment manufacturers now employ plasma-assisted deposition techniques, achieving 92% reflectance efficiency compared to traditional methods' 78%.

Manufacturing Capabilities Comparison

| Factory | Annual Capacity | Customization Options | Certifications |

|---|---|---|---|

| Factory A | 12,000 MT | 87 color variations | REACH, ISO 9001 |

| Factory B | 8,500 MT | 64 color variations | FDA, Halal |

| Factory C | 15,000 MT | 112 color variations | ISO 14001, ECOCERT |

Custom Formulation Development Process

Specialized pigment factories typically follow this development protocol:

- Requirement analysis (3-5 days)

- Lab-scale prototyping (14 days)

- Industrial testing (30 days)

- Batch production scaling (45 days)

This process enables 95% client specification compliance versus industry average of 82%.

Implementation in Commercial Products

A recent automotive coating project achieved:

- 48% improvement in UV resistance

- 31% reduction in material costs

- 0.92 ΔE color consistency over 5-year exposure

Cosmetics manufacturers report 22% higher customer preference for products containing custom mica pigments.

Environmental and Safety Considerations

Modern pigment factories have reduced:

- Water consumption by 65% (2018-2023)

- VOC emissions by 78%

- Energy usage per ton by 41%

Innovation Pathways for Mica Pigment Solutions

With 73% of custom pigment manufacturers investing in nanotechnology integration, future developments aim to achieve:

- Dynamic color-shifting capabilities (Δλ = 120nm)

- Self-healing surface structures

- Bio-compatible formulations for medical applications

(mica pigment powder)

FAQS on mica pigment powder

Q: What customization options are available for mica pigment powder?

A: Custom pigment manufacturers offer tailored colors, particle sizes, and finishes (e.g., metallic or matte). They can also adjust formulas for specific applications like cosmetics or coatings.

Q: How do I choose reliable custom pigment factories?

A: Prioritize factories with certifications (ISO, REACH), proven industry experience, and sample testing. Verify their production capacity and client reviews for quality assurance.

Q: Is mica pigment powder safe for cosmetic use?

A: Yes, if sourced from reputable custom pigment manufacturers. Ensure the powder meets FDA/EC standards and is free from heavy metals or allergens.

Q: What quality controls do custom pigment factories implement?

A: Factories use advanced testing like XRF and spectrophotometry to ensure color accuracy and consistency. Batch documentation and third-party audits are standard practices.

Q: What is the minimum order quantity for custom mica pigment powder?

A: MOQs vary by factory but typically start at 1-5 kg for testing. Bulk orders (100+ kg) often qualify for discounted rates and faster turnaround times.

Share

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025