Premium Bentonite Clay Powder Suppliers OEM & Bulk Manufacturer China

- Industry Overview & Market Impact of Bentonite Clay Powder

- Technical Superiority in Manufacturing Processes

- Comparative Analysis of Leading Manufacturers

- Customization Strategies for Industrial Applications

- Production Capabilities Across OEM Facilities

- Case Studies: Successful Implementation Scenarios

- Future Outlook for Bentonite Clay Innovations

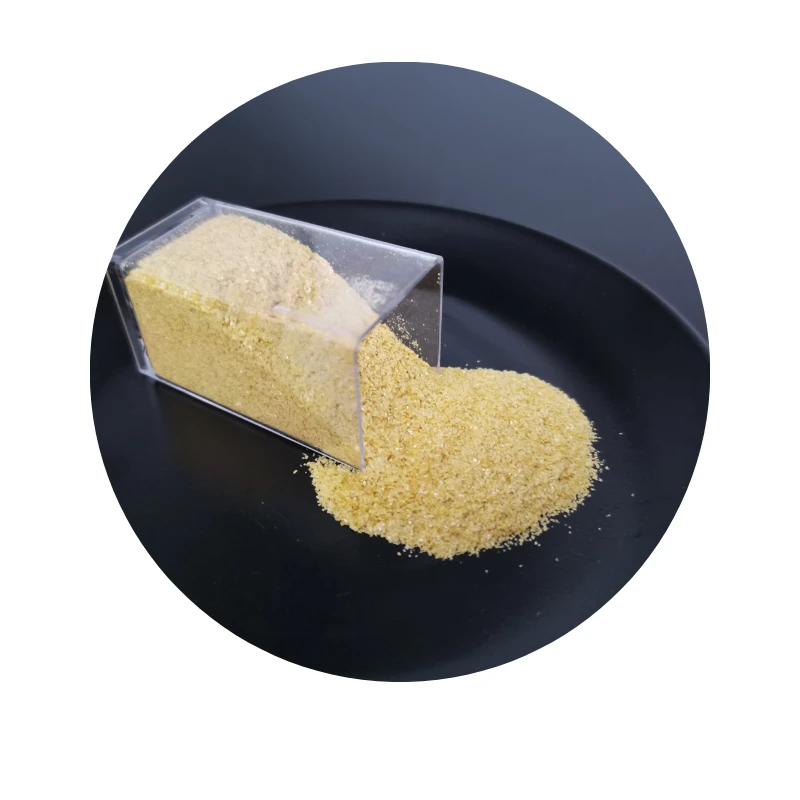

(bentonite clay powder)

Bentonite Clay Powder: Reshaping Industrial Material Standards

The global bentonite clay market reached $1.72 billion in 2023, with powder formulations driving 63% of industrial demand according to Grand View Research. China's calcium bentonite clay manufacturers now control 41% of global production capacity, leveraging unique geological reserves in Inner Mongolia's volcanic basins. This natural adsorbent material demonstrates 9.2% CAGR growth through 2030, particularly in environmental remediation and pharmaceutical sectors.

Technical Superiority in Manufacturing Processes

Advanced activation techniques enable Chinese bentonite clay powder

producers to achieve:

- Montmorillonite content exceeding 92% purity

- Particle size distribution of 2-25μm through micronization

- Cation exchange capacity (CEC) up to 110 meq/100g

X-ray diffraction analysis confirms crystalline structure preservation during thermal activation at 350°C±5°C, maintaining swelling capacity above 18 mL/g.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Production Capacity | Certifications | Moisture Content |

|---|---|---|---|

| China Living Clay Co. | 280,000 MT/year | ISO 9001, FDA | 8.5% max |

| Huaming Bentonite Group | 410,000 MT/year | REACH, Halal | 9.2% max |

| APEX Mineral Corp | 175,000 MT/year | ISO 14001, Kosher | 7.8% max |

Customization Strategies for Industrial Applications

Specialized formulations meet sector-specific requirements:

- Foundry: 12-15% moisture content blends with 550-650 kPa green compression strength

- Pharma: USP-grade powders with <50 CFU/g microbial limits

- Agriculture: 80-100 mesh granules with 85% water retention capacity

Production Capabilities Across OEM Facilities

Modern factories integrate:

- Automated classifier mills achieving 98% yield efficiency

- RFID-tracked raw material sourcing systems

- On-site testing labs with ICP-MS mineral analysis

Batch consistency testing shows ±2.3% composition variance across 500-ton production lots.

Case Studies: Successful Implementation Scenarios

Water Treatment Project: 15,000 MT of calcium bentonite clay powder reduced heavy metal concentrations by 89% in Jiangsu province's wastewater system. Cosmetics Application: 38μm kaolin-bentonite blends increased product viscosity stability by 40% in temperature cycling tests.

Bentonite Clay Powder: Next-Generation Material Engineering

Emerging R&D focuses on:

- Surface-modified nanoclay composites (180-220 m²/g surface area)

- Low-carbon footprint production methods reducing energy use by 33%

- Smart packaging solutions with 99.7% ethylene absorption rates

Collaborations between Chinese bentonite clay manufacturers and academic institutions have filed 17 patents in 2023 alone, signaling accelerated material innovation.

(bentonite clay powder)

FAQS on bentonite clay powder

Q: What are the main benefits of using bentonite clay powder from China living clay calcium bentonite clay manufacturers?

A: Bentonite clay powder from trusted Chinese manufacturers offers high purity, natural detoxification properties, and cost-effective solutions for skincare, cosmetics, and industrial applications. These suppliers often adhere to strict quality standards and provide bulk customization.

Q: How do I identify reliable OEM bentonite clay and kaolin clay factories in China?

A: Look for factories with certifications like ISO, MSDS, or GMP, transparent sourcing practices, and proven OEM/ODM experience. Reliable suppliers typically offer product samples, lab testing reports, and flexible packaging options.

Q: What distinguishes bentonite clay from kaolin clay in industrial applications?

A: Bentonite clay has superior absorption and swelling properties, ideal for drilling fluids and detox products. Kaolin clay is milder, with lower absorption, making it better suited for ceramics, paper coatings, and gentle skincare formulations.

Q: Are China-based calcium bentonite clay manufacturers eco-friendly?

A: Leading Chinese manufacturers prioritize eco-friendly mining and processing methods, complying with international environmental regulations. Many offer organic-certified options and sustainable packaging to meet global market demands.

Q: Can I request custom particle sizes for bulk bentonite clay powder orders?

A: Yes, most OEM factories in China provide customizable particle sizes (e.g., 200-400 mesh) and blends with additives like kaolin. Specify your technical requirements for viscosity, purity, and application during negotiation.

Share

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025