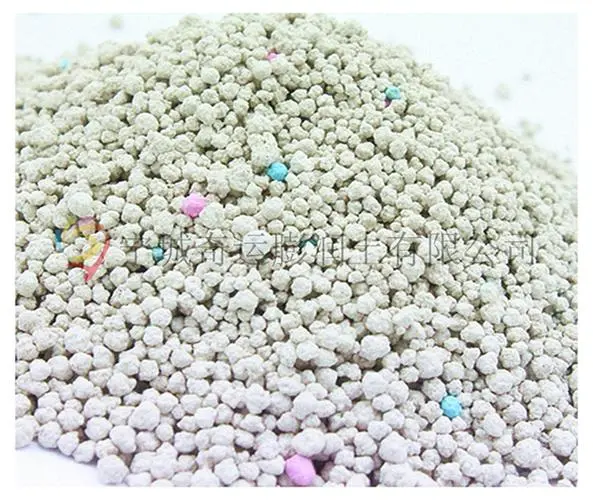

Custom Barite Powder for Mud Drilling Applications in Oil and Gas Industries

OEM Barite Powder for Mud Drilling A Comprehensive Overview

In the world of drilling, particularly in the oil and gas industry, the significance of high-quality drilling mud cannot be overstated. Among the various components that make up drilling mud, barite powder stands out due to its unique properties and essential roles. This article delves into the importance of OEM (Original Equipment Manufacturer) barite powder for mud drilling, its applications, benefits, and the factors to consider when sourcing it.

What is Barite Powder?

Barite, a mineral composed of barium sulfate (BaSO4), is widely known for its high density. This characteristic property makes barite powder an ideal additive for drilling mud. The powder is finely milled, resulting in a substance that can be easily mixed with other components to create a suitable drilling fluid. This fluid is crucial for controlling wellbore pressure, cooling the drill bit, and transporting cuttings to the surface.

The Role of Barite Powder in Mud Drilling

In mud drilling, barite powder serves multiple functions

1. Density Increase A primary function of barite in drilling mud is to increase the density of the fluid. This is essential for counteracting the pressure exerted by fluids in the rock formations, preventing blowouts and ensuring well stability.

2. Suspension and Carrying Capacity The high density of barite enables it to suspend drilled cuttings and carry them to the surface, maintaining a clear wellbore and facilitating efficient drilling operations.

3. Lubrication Barite powder enhances the lubricity of the drilling mud, reducing friction between the drill bit and the wellbore wall, which can minimize wear and tear on equipment.

4. Thermal Stability Drilling operations involve exposure to high temperatures. Barite powder contributes to the thermal stability of the drilling fluid, ensuring it performs well under varying temperature conditions.

Advantages of OEM Barite Powder

Opting for OEM barite powder for mud drilling comes with numerous advantages

oem barite powder for mud drilling

2. Custom Solutions OEM manufacturers can offer tailored barite powder solutions to meet the unique needs of different drilling projects, enhancing overall performance.

3. Consistency A reputable OEM supplier provides consistent quality in their products, which is critical for maintaining the stability of drilling operations and avoiding costly downtime.

4. Technical Support OEM suppliers typically offer technical support and expertise, assisting clients in optimizing the use of barite powder in their drilling processes.

Factors to Consider When Sourcing OEM Barite Powder

When looking for an OEM supplier of barite powder for mud drilling, consider the following factors

1. Quality Certifications Ensure that the supplier has relevant quality certifications, such as ISO or API standards, which guarantee the reliability and quality of their products.

2. Technical Expertise Choose a supplier with experience in the industry, as their expertise can be invaluable in recommending the right type and specifications of barite powder for your drilling needs.

3. Supply Chain Reliability Assess the supplier’s ability to meet demand consistently and deliver products in a timely manner. A reliable supply chain is crucial for uninterrupted drilling operations.

4. Environmental Considerations With increasing emphasis on sustainability, consider suppliers that practice environmentally responsible sourcing and processing methods.

5. Cost-Effectiveness While price is important, it should not compromise quality. Look for a balance between cost and product performance.

Conclusion

OEM barite powder is an indispensable component in the realm of mud drilling, providing essential benefits such as increased density, enhanced suspension capabilities, and improved thermal stability. By understanding its significance and considering the key factors for sourcing, drilling companies can ensure they select the right suppliers to support their operational needs. Investing in high-quality barite powder will contribute to safer, more efficient, and more cost-effective drilling operations, ultimately enhancing productivity and profitability in the industry.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025