fly ash making

The Emerging Potential of Fly Ash in Sustainable Construction

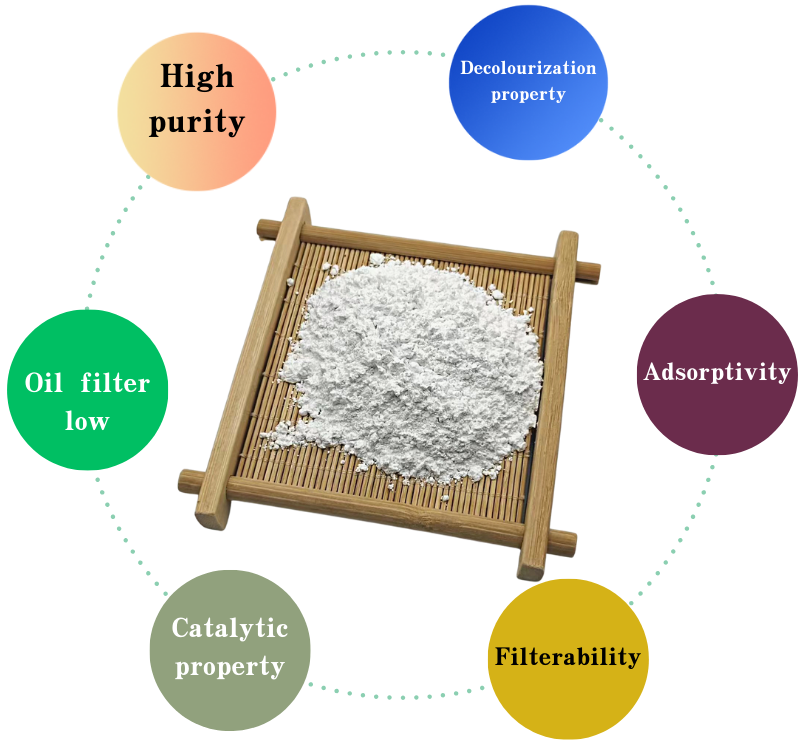

Fly ash, a by-product of coal combustion in power plants, has gained significant attention in the field of construction and civil engineering due to its potential to enhance the sustainability of building materials. As the world increasingly focuses on reducing carbon emissions and fostering environmentally friendly practices, the utilization of fly ash in various applications presents an innovative solution to meet these challenges.

When coal is burned to generate electricity, the combustion process produces fly ash, which is carried away by flue gases and collected using electrostatic precipitators or baghouses. This fine, powdery substance is primarily composed of silica, alumina, and calcium oxide, along with other trace elements. Traditionally, fly ash was often relegated to landfills, creating environmental hazards. However, it was later discovered that fly ash could be an effective additive for cement and concrete production, leading to a paradigm shift in how this material is perceived.

The integration of fly ash into concrete formulations can significantly improve the material's properties. For instance, incorporating fly ash reduces the heat of hydration, making it particularly beneficial for large pour applications where temperature control is critical. Moreover, fly ash enhances the workability of concrete, allowing for easier placement and finishing processes. One of the most remarkable advantages is its ability to increase the durability and longevity of concrete structures. The pozzolanic properties of fly ash enable it to react with calcium hydroxide in the presence of water to form additional calcium silicate hydrate, thus contributing to the strength and resilience of the concrete over time.

fly ash making

Beyond its physical benefits, the use of fly ash in construction contributes to sustainability efforts. By replacing a portion of traditional cement, which is a significant source of CO2 emissions during production, fly ash mitigates the carbon footprint associated with concrete manufacturing. The cement industry is responsible for approximately 8% of global carbon emissions, and every ton of cement replaced by fly ash can save about 0.8 tons of CO2 from being emitted into the atmosphere. This not only aids in achieving sustainable development goals but also aligns with various green building certification systems, such as LEED (Leadership in Energy and Environmental Design).

Furthermore, the increasing demand for sustainable materials has led to innovative applications of fly ash beyond traditional concrete mixtures. It can be used in the production of lightweight aggregates, brick manufacturing, road base materials, and even as a filler in asphalt. Each of these applications not only diverts fly ash from landfills but also promotes the circular economy by utilizing waste materials in valuable construction products.

Despite the numerous advantages of using fly ash, challenges remain. Variability in the composition of fly ash due to different coal sources can affect its performance and consistency in concrete applications. There is also the concern regarding the presence of heavy metals in certain fly ashes, which necessitates rigorous testing and monitoring before use in construction. However, advances in technology and better production processes are gradually addressing these issues.

In conclusion, the increasing utilization of fly ash in construction represents a significant step towards sustainable building practices. By harnessing this industrial by-product, we can reduce waste, lower carbon emissions, and enhance the performance of construction materials. As awareness of environmental issues grows, the demand for innovative solutions like fly ash will undoubtedly continue to rise, paving the way for a more sustainable future in the construction industry.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025