Custom Dolomite Powder Production by Leading Manufacturer for Various Industrial Applications

Custom Dolomite Powder Manufacturer Meeting Unique Industrial Needs

In today’s competitive industrial landscape, the demand for specialized raw materials is at an all-time high. One such material that has garnered significant attention is dolomite powder. This versatile mineral, primarily composed of calcium magnesium carbonate, has a wide array of applications in various sectors, including construction, agriculture, pharmaceuticals, and more. However, as industries evolve and require more tailored solutions, the role of a custom dolomite powder manufacturer has become increasingly vital.

Understanding Dolomite Powder

Dolomite powder is acquired by crushing dolomite rock and grinding it into a fine powder. This process ensures that the mineral retains its unique properties, which include chemical stability, good dispersion, and enhanced durability. Its attributes make it an ideal choice for applications such as

- Construction Materials Used as a building stone and as a component in cement, dolomite helps enhance the structural integrity of buildings and other infrastructures. - Agriculture Dolomite powder acts as a soil conditioner, helping to improve soil pH and nutrient availability, hence augmenting crop yields. - Glass and Ceramics Its unique properties make it an essential ingredient in the production of glass and ceramics, improving the final product's strength and transparency. - Pharmaceuticals In the pharmaceutical industry, dolomite powder serves as an excipient due to its chemical composition being benign and safe for consumption.

The Importance of Customization

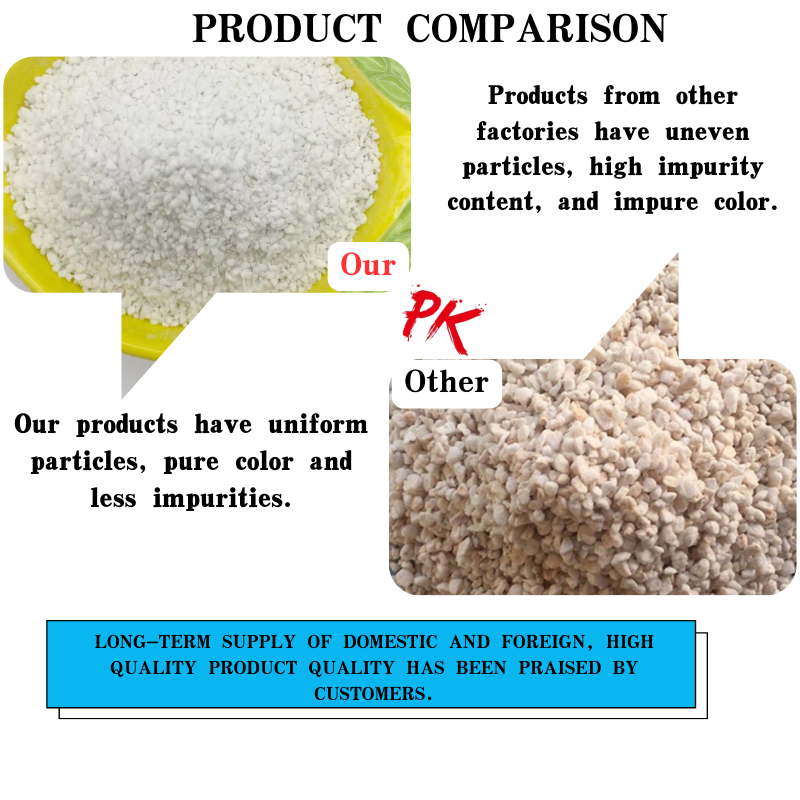

While dolomite powder is widely used, not all applications require the same type or grade of dolomite. This is where custom dolomite powder manufacturers play a crucial role. By understanding the specific needs of their clients, these manufacturers can produce dolomite powder that meets exact specifications regarding particle size, purity levels, and other characteristics.

For instance, the agricultural sector may require finer dolomite powder to better integrate it into soil, whereas the construction industry may favor coarser granules for added structural benefits. Similarly, the pharmaceutical industry demands extremely high purity levels to ensure safety in its applications. Custom manufacturers are equipped to handle these diverse requirements, ensuring that their products are tailored to the unique demands of each sector.

custom dolomite powder manufacturer

Quality Assurance and Production Processes

A reliable custom dolomite powder manufacturer employs stringent quality assurance protocols at every stage of the production process. This includes selecting high-grade raw dolomite, using advanced crushing and milling technologies, and conducting thorough testing to ensure that the final product meets industry standards. Implementing quality control measures not only guarantees product consistency but also ensures compliance with various regulatory requirements, particularly in sensitive sectors like pharmaceuticals and food production.

Additionally, many manufacturers are also investing in sustainable practices. As industries become more environmentally conscious, there is a growing demand for green manufacturing processes. This includes minimizing waste, reducing energy consumption, and using eco-friendly materials without compromising on quality.

The Future of Custom Dolomite Production

The future looks promising for custom dolomite powder manufacturers. With advancements in technology and a greater emphasis on customization, these manufacturers are poised to meet the evolving needs of diverse industries. The rise of innovative applications, such as biocompatible materials for healthcare and eco-friendly construction solutions, presents new opportunities for growth.

Moreover, the global market for dolomite powder is expected to expand as emerging markets recognize the benefits of using dolomite in a wide range of applications. Custom manufacturers are likely to play an integral role in this expansion by providing tailored solutions that cater to both established and budding industries worldwide.

Conclusion

In conclusion, as industries continue to demand specialized materials, the role of custom dolomite powder manufacturers is becoming increasingly critical. By understanding client needs and providing tailored solutions, these manufacturers are not only contributing to the quality of end products but also driving innovation across various sectors. Whether in construction, agriculture, or pharmaceuticals, the expertise of a custom dolomite powder manufacturer is invaluable in ensuring that industries have the materials they need to thrive in a competitive market.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025