oem titanium dioxide rutile and anatase factories

The Production and Applications of Titanium Dioxide Rutile and Anatase Forms

Titanium dioxide (TiO2) is a versatile and essential inorganic compound widely utilized across various industries due to its excellent properties. Among its different crystalline forms, rutile and anatase are the most significant, each exhibiting distinct characteristics that make them suitable for specific applications. This article explores the production processes, properties, and uses of these two forms of titanium dioxide.

Production of Titanium Dioxide

Titanium dioxide can be produced through two primary methods the sulfate process and the chloride process. The sulfate process involves using sulfuric acid to convert titanium-containing ores into titanium sulfate, which is then hydrolyzed to produce TiO2. This method is characterized by lower purity of the final product and higher environmental impacts due to the management of sulfuric acid waste.

In contrast, the chloride process utilizes chlorine gas at high temperatures to convert titanium ores (such as ilmenite) into titanium tetrachloride (TiCl4). The TiCl4 is then oxidized to produce high-purity titanium dioxide. This method is more efficient and results in a cleaner product, making it the preferred choice for manufacturers aiming for superior TiO2 quality.

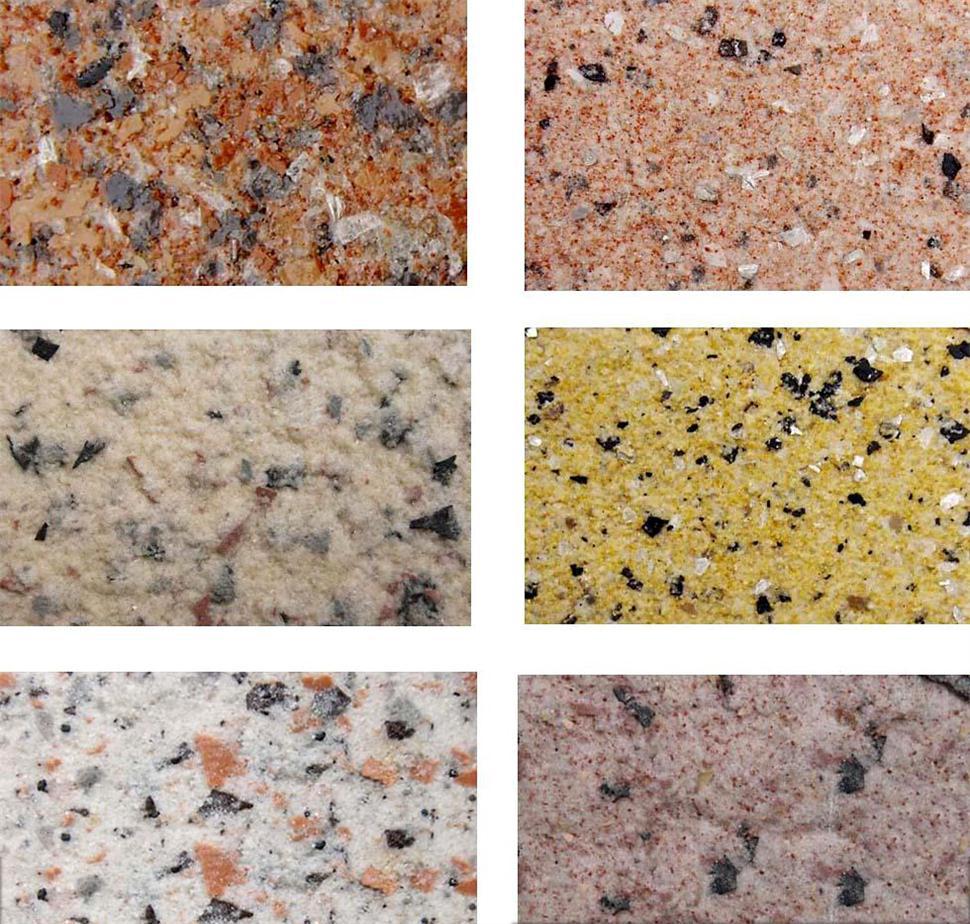

Rutile vs. Anatase Properties and Characteristics

Rutile and anatase are two different crystalline structures of titanium dioxide, each with unique properties. Rutile, with a tetragonal crystal system, is thermodynamically stable at higher temperatures and exhibits superior durability and opacity. It is known for its high refractive index, making it an excellent choice for applications requiring brightness and whiteness, such as paints, coatings, and plastics.

Anatase, on the other hand, is less stable than rutile but demonstrates unique photocatalytic properties

. Its tetragonal structure allows for higher surface area, making it effective in applications that require light absorption and catalysis, such as in the production of self-cleaning surfaces and environmental remediation processes.oem titanium dioxide rutile and anatase factories

Applications of Titanium Dioxide

The applications of titanium dioxide are vast and varied. In the paint and coatings industry, rutile TiO2 is often favored for its ability to enhance opacity and durability, ensuring that finished products have a vibrant and long-lasting appearance. It serves as a critical ingredient in both interior and exterior paints, offering protection against UV rays and harsh weather conditions.

In the plastics industry, titanium dioxide is utilized to provide whiteness and opacity in products ranging from packaging materials to consumer goods. The automotive industry also employs rutile TiO2 in coatings to achieve high gloss and protection against scratches, thereby enhancing the aesthetic appeal and longevity of vehicles.

Anatase TiO2 shines in the field of photocatalysis. Its ability to decompose organic pollutants under UV light is harnessed in various applications, including air and water purification systems. Additionally, it is used in the development of self-cleaning surfaces, where its photocatalytic properties enable the degradation of dirt and grime without the need for harsh chemicals.

In the electronics industry, titanium dioxide is finding uses in the manufacturing of semiconductors and as a dielectric material in capacitors. Its unique properties make it an attractive choice for advanced electronic applications, contributing to the development of efficient and high-performance devices.

Conclusion

The demand for titanium dioxide, particularly in its rutile and anatase forms, continues to grow as industries seek materials that meet their quality and performance standards. Manufacturers around the world are investing in the production of high-purity TiO2 to cater to the needs of various sectors, from coatings and plastics to environmental and electronic applications. As innovation drives new uses for this versatile compound, titanium dioxide remains a crucial material in the fabric of modern technology and industry.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025