Large Scale Perlite Production Facilities for Enhanced Industrial Use and Efficiency

The Role of Large Perlite Factories in Modern Industry

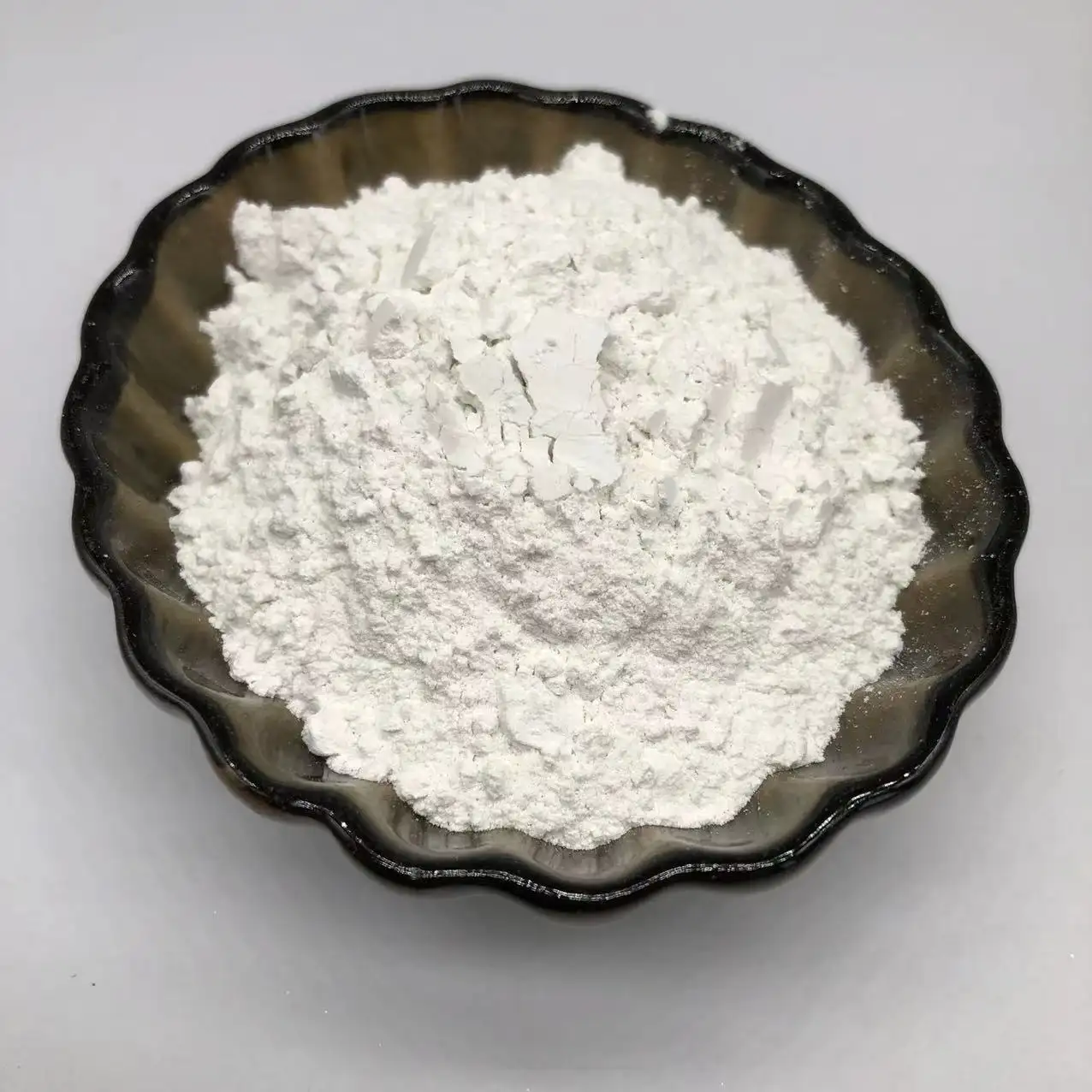

Perlite, a naturally occurring volcanic glass, has gained significant traction in various industries over the years. Its lightweight, insulating, and moisture-retaining properties make it an essential component in construction, agriculture, horticulture, and even as a filler in various products. As the demand for perlite continues to rise, large perlite factories are playing a crucial role in meeting the needs of various sectors and contributing to the growth of sustainable practices.

One of the primary functions of large perlite factories is to process volcanic glass into workable perlite products. The transformation begins with the extraction of raw perlite ore, which is then crushed and heated to high temperatures in an expansion process. This process transforms the dense, raw perlite into lightweight expanded perlite, which can then be categorized into various grades based on size and applications. Large factories possess the required machinery and technology to efficiently perform these tasks, ensuring that the output meets the stringent quality standards expected by modern customers.

In the construction industry, expanded perlite is highly valued for its lightweight and insulating properties. It is used as an aggregate in lightweight concrete, which not only reduces the overall weight of structures, thereby making them easier to build, but also improves thermal insulation. This aspect is increasingly important in an era where energy efficiency is prioritized. Moreover, large perlite factories can supply materials in bulk, meeting the growing demands of large construction projects and enabling architects and builders to design energy-efficient structures without compromising on strength.

large perlite factories

The agricultural sector also benefits from the operations of large perlite factories. Expanded perlite is commonly used as a soil amendment, enhancing aeration, drainage, and moisture retention. These qualities are particularly crucial for growing healthy plants. In the era of climate change, where water scarcity is becoming a significant issue, utilizing perlite in agricultural practices can contribute to more sustainable farming methods. Large perlite factories are well equipped to produce the volumes needed to support commercial agriculture, ensuring that farmers can achieve higher yields with fewer resources.

Horticulture also relies heavily on perlite, especially for potting mixes and hydroponics. The use of perlite in these scenarios aids in maintaining optimal growth conditions for plants. Large-scale production of perlite allows for standardized, high-quality products that can be distributed widely to nurseries and garden centers. This availability ensures that plant enthusiasts and professional growers have access to the necessary materials to cultivate healthy flora.

Perlite is also used in numerous industrial applications, including as a filler in plastics, rubber, and paints. Its ability to enhance properties without significantly adding weight makes it a preferred choice among manufacturers. Large perlite factories can produce specific grades of perlite to meet the particular needs of these industries, allowing for innovation and optimization of product formulations.

In conclusion, large perlite factories are indispensable in today’s market, fulfilling the increasing demand for high-quality perlite across various sectors. Their ability to efficiently process and supply large quantities of expanded perlite not only supports the construction and agricultural industries but also contributes to more sustainable practices. As industries continue to evolve, the role of these factories will only grow in importance, ensuring that perlite remains a vital component in building a sustainable future. The synergy between large perlite factories and the industries they serve exemplifies how natural resources can be harnessed effectively to meet modern challenges and support economic growth.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025