oem fired clay pebbles factories

The Rise of OEM Fired Clay Pebbles Factories A Comprehensive Overview

In recent years, the demand for environmentally friendly construction materials has surged significantly, spurring innovation and production within various industries. Among these, the emergence of OEM (Original Equipment Manufacturer) fired clay pebbles factories has gained notable attention. These specialized facilities are at the forefront of producing high-quality fired clay pebbles, which are crucial for several applications, ranging from landscaping to hydroponics. This article delves into the importance, production process, benefits, and future prospects of OEM fired clay pebbles.

What are Fired Clay Pebbles?

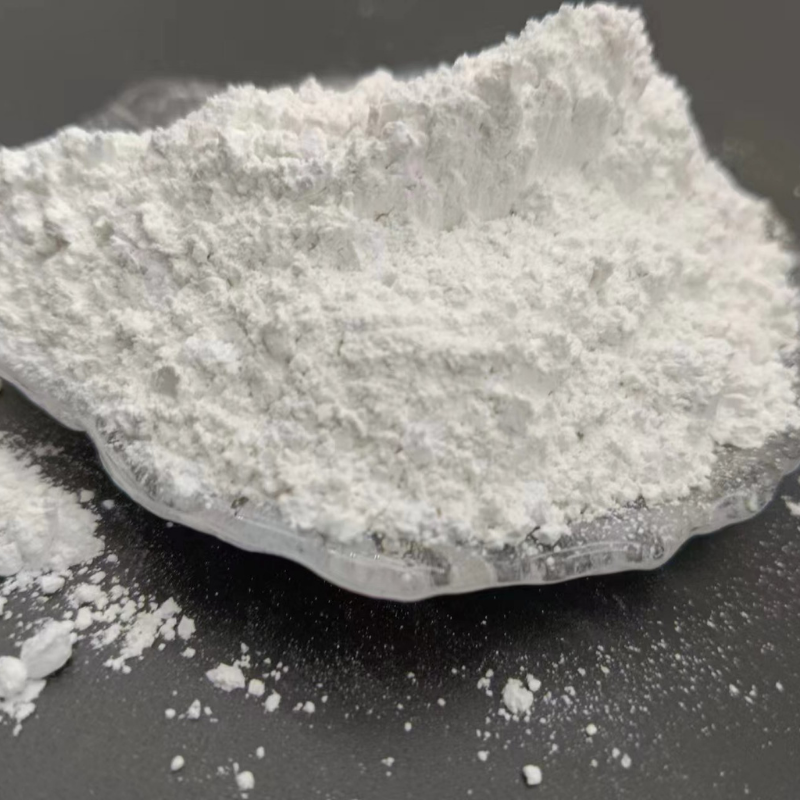

Fired clay pebbles, also known as expanded clay aggregates or LECA (Lightweight Expanded Clay Aggregate), are produced by heating clay to high temperatures, causing it to expand and form lightweight, porous pebbles. These pebbles possess remarkable properties, including excellent drainage capabilities, good insulation, and reduced weight compared to traditional aggregates. Their unique characteristics make them highly sought after in various industries.

The OEM Advantage

OEM fired clay pebbles factories offer several advantages that appeal to both manufacturers and consumers. Firstly, these factories produce high-quality products tailored to specific customer requirements. Companies can customize the size, shape, and packaging of the pebbles according to their unique needs, ensuring a more personalized experience.

Moreover, OEM manufacturers typically maintain strict quality control processes. By adhering to industry standards, they ensure that the fired clay pebbles produced are consistent and reliable. This consistency not only enhances product performance but also builds trust among clients.

The Production Process

The production of fired clay pebbles involves several critical steps

1. Raw Material Selection High-quality clay is sourced, which may include natural additives to enhance the properties of the final product.

2. Preparation The clay undergoes a preparation phase, where it is crushed, mixed, and conditioned to achieve the desired consistency.

3. Granulation The prepared clay is formed into small pellets or granules. This process is crucial, as the size of the pellets affects the final product’s drainage properties and structural integrity.

4. Firing The granulated clay is then subjected to high temperatures in a kiln. This firing process causes the clay to expand and form the lightweight pebbles that characterize this product.

oem fired clay pebbles factories

6. Packaging and Distribution Finally, the pebbles are packaged for distribution, often in varying quantities to suit different customer needs.

Applications of Fired Clay Pebbles

Fired clay pebbles have a diverse range of applications that underline their versatility

- Hydroponics Their excellent drainage and aeration qualities make them ideal for hydroponic gardening systems, helping promote healthy root development.

- Landscaping Used as decorative aggregates or in green roofs, fired clay pebbles provide both aesthetic appeal and functional benefits such as moisture retention and erosion control.

- Construction Lightweight and strong, they serve as excellent lightweight aggregate replacements in concrete, reducing the overall weight of structures without compromising strength.

- Filtration Their porous nature allows them to be employed in water filtration systems, helping purify and aerate water in various applications.

Environmental Benefits

One of the most compelling reasons for the increasing demand for fired clay pebbles is their environmental friendliness. The production process is relatively energy-efficient, particularly when compared to conventional aggregates. Additionally, their lightweight nature leads to reduced transportation costs and emissions. The materials are also inherently recyclable, making them a sustainable choice for eco-conscious consumers.

Future Prospects

The future looks bright for OEM fired clay pebbles factories. As urbanization continues to rise, there will be an increasing need for efficient, sustainable building materials. Advances in technology may further enhance the production process, leading to even more efficient manufacturing methods.

Moreover, the growing awareness of climate change and sustainability will likely drive innovations focused on reducing environmental impact. Manufacturers may also explore incorporating recycled materials into their products, further promoting sustainability.

In conclusion, OEM fired clay pebbles factories are playing a pivotal role in the evolution of sustainable materials in construction and landscaping. Their tailored production, combined with the numerous benefits of fired clay pebbles, positions them as a vital asset to various industries. As the focus on eco-friendly materials continues to rise, these factories will undoubtedly expand their influence and reach in the coming years.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025