china silica fume production factory

Silica fume, a byproduct of silicon and ferrosilicon production, has gained significant attention in the construction and manufacturing industries. In recent years, China has emerged as one of the largest producers of silica fume, with numerous factories dedicated to its production. This article will explore the processes involved in silica fume production in China, the applications of the material, and its environmental benefits.

The production of silica fume in China mainly occurs in facilities located near silicon metal and ferrosilicon manufacturing plants. The process begins with the extraction of quartz and other silica-rich materials, which undergo high-temperature reduction in electric arc furnaces. During this process, a substantial amount of fine silica particles is generated as a byproduct. These ultra-fine particles, primarily composed of silicon dioxide (SiO2), are collected and processed to create silica fume.

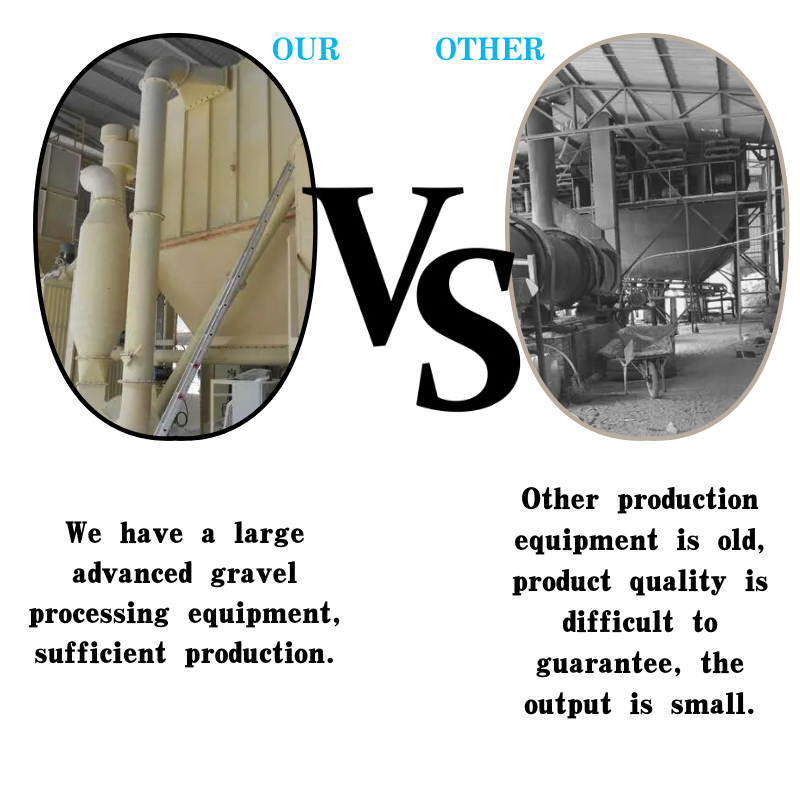

Chinese silica fume production factories employ advanced technology to ensure high efficiency and low emissions. State-of-the-art collection systems capture the silica fume released during the production process, reducing air pollution. The material is then treated and packaged for distribution, meeting international quality standards. This commitment to quality makes Chinese silica fume highly sought after in both domestic and international markets.

Silica fume has a wide range of applications, particularly in the construction industry. It is commonly used as a supplementary cementitious material (SCM) in concrete production. When added to concrete mixes, silica fume enhances the strength, durability, and workability of the final product. It fills the voids between cement particles, resulting in a denser and more cohesive mixture. This leads to improved resistance to water penetration, chemical attacks, and freeze-thaw cycles, making silica fume concrete ideal for infrastructure projects, such as bridges, roads, and high-rise buildings.

china silica fume production factory

In addition to its use in concrete, silica fume finds application in other areas, including the production of high-performance mortars and grouts, as well as in the manufacturing of advanced ceramics and composites

. Its properties make it an excellent choice for industries requiring materials with enhanced mechanical properties and chemical resistance.One of the significant advantages of using silica fume is its environmental impact. As it is a byproduct of silicon metal production, its utilization helps in reducing waste and promoting recycling within the industry. By substituting a portion of cement with silica fume, manufacturers can lower their carbon footprint, as the production of cement is a major source of greenhouse gas emissions. In this way, silica fume can contribute to more sustainable construction practices.

Furthermore, the adoption of silica fume in concrete can enhance the longevity of structures, reducing the need for frequent repairs and maintenance. This not only conserves resources but also minimizes the embodied energy associated with rebuilding and refurbishing, further supporting environmental sustainability.

In conclusion, China's silica fume production factories play a crucial role in meeting the growing demand for this valuable material. With advanced production techniques, a commitment to quality, and a focus on sustainable practices, these facilities contribute significantly to the construction industry. As awareness of the environmental benefits of silica fume continues to rise, its applications are likely to expand, paving the way for more innovative and sustainable construction solutions.

Share

-

Custom Expand Vermiculite Manufacturing & High-Temperature SolutionsNewsApr.29,2025

-

Calcium Powder Suppliers High-Purity Carbonate, Oxide & PhosphateNewsApr.29,2025

-

Custom Perlite Mine Solutions Expert Manufacturing & FactoriesNewsApr.28,2025

-

Premium Zeolite Bentonite Manufacturers in China OEM FactoriesNewsApr.28,2025

-

Reflective Glass Beads for Paint & OEM Manufacturing - China FactoryNewsApr.28,2025

-

Custom Aluminium Oxide Grinding Services Precision & DurabilityNewsApr.28,2025