china silica fume and fly ash in concrete factory

The Role of Silica Fume and Fly Ash in Concrete Production in China

In recent years, the construction industry in China has witnessed a significant transformation, largely driven by the incorporation of advanced materials in concrete production. Among these materials, silica fume and fly ash have emerged as two critical ingredients enhancing the performance of concrete. This article explores the benefits, applications, and future prospects of using silica fume and fly ash in concrete factories across China.

Understanding Silica Fume and Fly Ash

Silica fume, a by-product of silicon and ferrosilicon alloy production, consists of very fine particles that can fill the voids in concrete, enhancing its density and strength. On the other hand, fly ash, produced from the combustion of pulverized coal in electric power plants, serves as a pozzolanic material that reacts with calcium hydroxide in the presence of water to form compounds that contribute to the strength and durability of concrete.

Enhancing Concrete Properties

The inclusion of silica fume and fly ash in concrete mixes leads to several improvements in both fresh and hardened concrete. When added to concrete, silica fume can significantly reduce porosity, increase compressive strength, and enhance resistance to chemical attacks. This is particularly advantageous in environments where concrete is exposed to aggressive substances like chlorides and sulfates, making it an ideal choice for infrastructure projects such as bridges and tunnels.

Fly ash, while securing many similar benefits, primarily improves workability and reduces water demand in concrete mixtures. The spherical shape of fly ash particles allows for better flow, which is essential for complex shapes, especially in precast concrete elements. Additionally, incorporating fly ash can contribute to a lower carbon footprint, making concrete production more sustainable.

Economic and Environmental Advantages

The use of silica fume and fly ash not only enhances the mechanical properties of concrete but also offers considerable economic benefits. By substituting a portion of Portland cement with these materials, concrete producers can achieve cost-saving efficiencies. This substitution reduces the quantity of cement needed, which is not only expensive but also has a high carbon dioxide footprint during production.

china silica fume and fly ash in concrete factory

From an environmental standpoint, the use of silica fume and fly ash aligns with global sustainability goals. As China strives to reduce its environmental impact, the recycling of industrial by-products like fly ash and the use of silica fume help minimize waste and make better use of existing resources. The construction industry can thus play a pivotal role in lowering greenhouse gas emissions.

Challenges in Implementation

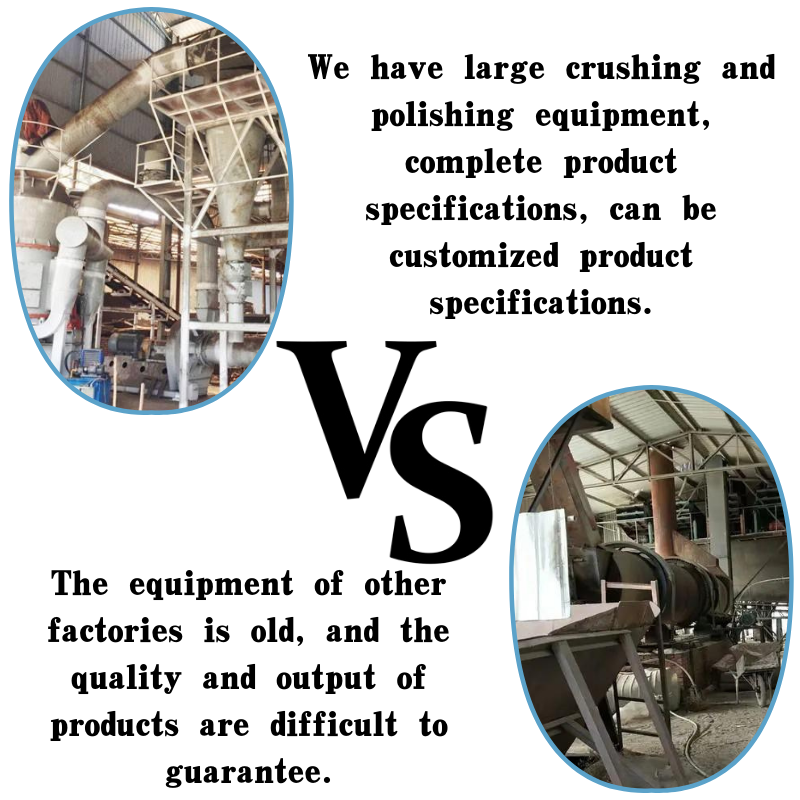

Despite the clear benefits, the adoption of silica fume and fly ash in concrete production is not without challenges. Careful control of material quality is crucial since variations in the properties of these by-products can adversely affect concrete performance. Additionally, the higher silica fume content can lead to increased water demand and workability issues if not properly managed.

Moreover, there is a need for more extensive research and development to optimize mix designs and application techniques specifically tailored to various construction environments found in China. Educating stakeholders, including engineers and construction firms, about the benefits and best practices of using these materials is also vital for their widespread adoption.

Future Prospects

The future of concrete production in China looks promising with increasing recognition of the advantages of silica fume and fly ash. Government policies that encourage the use of industrial by-products in construction are likely to gain momentum. Innovations in processing and applications will further enhance the performance of concrete containing these materials.

In addition, the growing trend of smart construction techniques, coupled with advancements in concrete technology, offers a fertile ground for the integration of silica fume and fly ash. Initiatives aimed at recycling and sustainability will reflect in the operational strategies of concrete factories as they seek ways to reduce carbon emissions and enhance the longevity of structures.

Conclusion

Silica fume and fly ash represent a significant step towards more sustainable and resilient concrete production in China. As the construction industry continues to evolve, the integration of these materials not only improves concrete properties but also promotes environmental consciousness and economic efficiency. Embracing these advancements will be crucial for the future of construction, ensuring that it meets the demands of a growing urban population while minimizing its impact on the planet.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025