Zeolite Stone Manufacturer for High-Quality Mineral Products and Sustainable Solutions

Zeolite Stone Factory Harnessing Nature's Mineral Power

In the ever-evolving landscape of construction materials, the demand for innovative and sustainable options continues to rise. Among these alternatives, zeolite stone has garnered significant attention for its unique properties and versatility. This article delves into the world of zeolite stone factories, exploring their production processes, applications, and the benefits they offer to various industries.

What is Zeolite?

Zeolites are naturally occurring or synthetic minerals that belong to the aluminosilicate family. Composed of silicon, aluminum, and oxygen, they possess a unique crystalline structure that allows them to adsorb and exchange ions. This characteristic makes zeolites highly valuable in various applications, ranging from water purification to agriculture and construction.

The Zeolite Stone Factory Process

The journey of zeolite from its natural form to a finished product involves several stages. First, raw zeolite ore is extracted from mining sites. The ore typically undergoes crushing and milling to achieve the desired particle size. After this, the material is mixed with water and other additives to enhance its properties. The mixture is then shaped into stones or granules using advanced forming techniques.

Once shaped, the zeolite is subjected to a drying process to eliminate moisture content. This step is crucial, as excess water can compromise the integrity and performance of the final product. After drying, the zeolite stones are often subjected to a calcination process, where they are heated to high temperatures. This step enhances their structural stability and activates their ion-exchange capabilities.

Quality control is a critical aspect of zeolite stone production. Factories implement rigorous testing protocols to ensure that the final product meets industry standards. This includes evaluating chemical composition, particle size distribution, and adsorption capacity. By adhering to these quality checks, zeolite stone factories can assure customers of their products' reliability and effectiveness.

Applications of Zeolite Stone

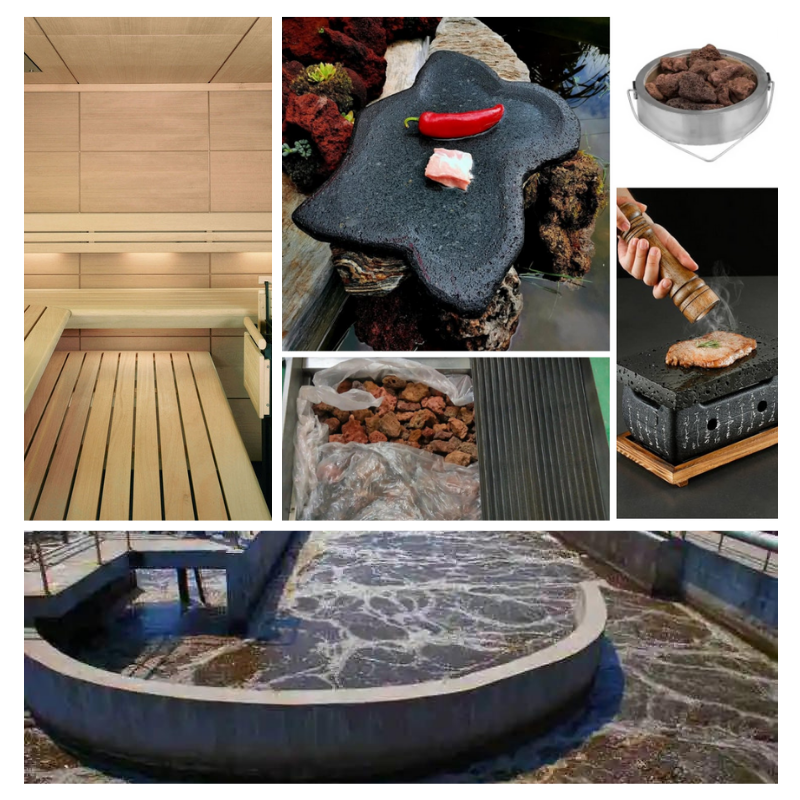

zeolite stone factory

Zeolite stone has a multitude of applications. In the construction industry, it is often used as an additive in cement and concrete, where it improves durability and reduces shrinkage. The incorporation of zeolite enhances the mechanical properties of concrete while minimizing the environmental impact typically associated with traditional materials.

Furthermore, zeolite stones are used in soil amendments for agriculture. Their ion-exchange properties help retain essential nutrients and moisture in the soil, promoting healthier plant growth. This not only boosts agricultural productivity but also contributes to sustainable farming practices by reducing the need for chemical fertilizers.

Another prominent application is in water treatment. Zeolites are effective in removing heavy metals and toxins from wastewater, making them invaluable in environmental remediation efforts. Their ability to filter pollutants and improve water quality has made them a preferred choice for industries seeking to minimize their ecological footprint.

The Sustainability Factor

One of the key advantages of zeolite stone production is its alignment with sustainable practices. The extraction and processing of zeolite typically have a lower environmental impact compared to many other materials. Being a naturally occurring mineral, zeolite is abundant and can be sourced responsibly.

Moreover, the use of zeolites in various applications contributes to resource conservation. By enhancing the efficiency of materials such as concrete and fertilizers, zeolites help reduce waste and lower the overall carbon footprint of industries. As sustainability becomes a central theme across sectors, zeolite stone factories play a crucial role in providing eco-friendly solutions.

Future Outlook

As industries increasingly prioritize sustainable practices, the future looks bright for zeolite stone factories. Advances in technology and innovative production methods are likely to enhance the efficiency and effectiveness of zeolite products. Furthermore, ongoing research into new applications will expand the market potential for zeolite stones, driving demand in diverse sectors.

In conclusion, zeolite stone factories are at the forefront of providing sustainable, versatile materials that cater to various industrial needs. From construction to agriculture and water treatment, the applications of zeolite are vast and impactful. As we continue to seek environmentally friendly solutions, zeolite stones stand out as a promising option, marrying effectiveness with sustainability.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025