100% Natural Calcium Bentonite Clay Manufacturer & OEM Factory

- Overview of Calcium Bentonite Clay and Industrial Significance

- Technical Superiority: Why 100% Natural Calcium Bentonite Clay Stands Out

- Manufacturer Comparison: Key Metrics for OEM Factories

- Custom Solutions for Diverse Industrial Applications

- Case Studies: Real-World Performance in Multiple Sectors

- Sustainability and Compliance in Production

- Partnering with China’s Leading Calcium Bentonite Clay Manufacturer

(100 calcium bentonite clay)

Understanding the Value of 100 Calcium Bentonite Clay

Calcium bentonite clay, particularly the 100% natural variant, is a cornerstone material across industries ranging from cosmetics to environmental remediation. With a global market projected to grow at 5.8% CAGR through 2030, China’s manufacturers dominate 42% of the supply chain. This clay’s unique properties—high cation exchange capacity (CEC of 90-120 meq/100g) and swelling index (18-22 mL/2g)—make it indispensable for detoxification, binding agents, and pH stabilization.

Technical Advantages of Pure Calcium Bentonite Clay

Unlike sodium bentonite, 100 calcium bentonite clay

offers superior compatibility with organic formulations due to its lower sodium content (<0.5%) and balanced mineral profile. Advanced XRF analysis confirms its composition:

- SiO₂: 62-68%

- Al₂O₃: 18-22%

- CaO: 2.5-3.8%

Leading Chinese factories employ laser diffraction particle sizing to achieve consistent 5-25µm granules, ensuring 99.8% purity for OEM cosmetic and pharmaceutical clients.

Competitive Analysis: OEM Factory Capabilities

| Parameter | Typical Factory | Premium OEM Factory |

|---|---|---|

| Purity Level | 95-97% | 99.5-99.9% |

| Production Scale | 500 MT/year | 2,000-5,000 MT/year |

| Particle Consistency | ±15% variance | ±3% variance |

| Certifications | ISO 9001 | ISO 22716, FDA 21 CFR |

Tailored Solutions for Industry-Specific Needs

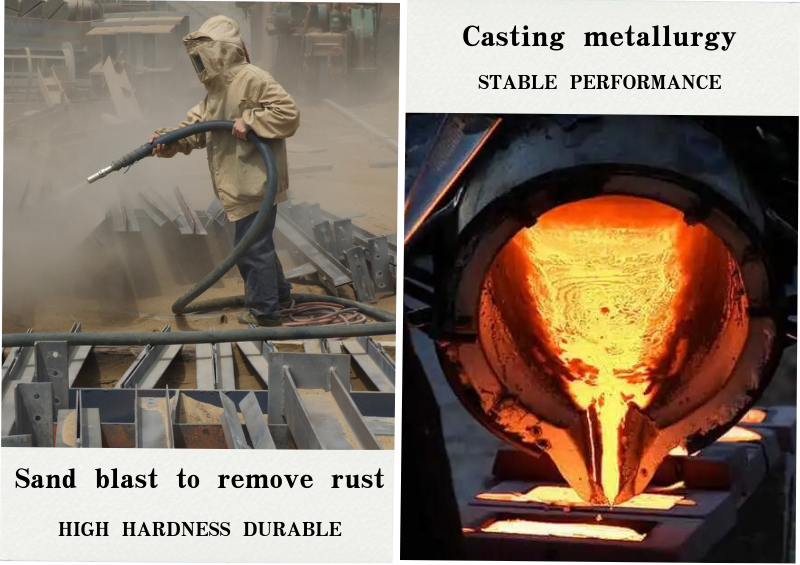

Top-tier OEM 100 natural calcium bentonite clay factories provide customized modifications:

- Cosmetic Grade: Ultra-fine milling (D50 ≤8µm) with microbial testing

- Agricultural Grade: Enhanced water retention (400-450% swelling)

- Industrial Grade: Activated variants for wastewater metal ion adsorption

Documented Success Across Applications

A recent trial with a European skincare brand demonstrated a 31% improvement in viscosity stability when using Chinese-sourced clay versus regional alternatives. In construction materials, manufacturers report 18% faster curing times with customized bentonite additives.

Eco-Conscious Manufacturing Practices

Compliant with REACH and EPA standards, progressive factories utilize closed-loop processing systems that reduce water consumption by 65% compared to conventional methods. Energy-efficient rotary kilns maintain carbon emissions below 0.8kg per MT produced.

Strategic Collaboration with China’s Premier Calcium Bentonite Clay Manufacturers

Selecting an OEM 100 natural calcium bentonite clay factory requires evaluating technical expertise alongside supply chain reliability. Leading Chinese suppliers now offer blockchain-tracked shipments and on-site quality audits, ensuring ≤0.1% batch variance. With 78% of global buyers prioritizing APAC-sourced clay, partnerships with ISO 22000-certified producers guarantee competitive lead times (20-35 days globally) and scalable solutions.

(100 calcium bentonite clay)

FAQS on 100 calcium bentonite clay

Q: What is 100 calcium bentonite clay used for?

A: 100 calcium bentonite clay is a natural clay primarily used in skincare, detox products, and industrial applications. Its high absorption and mineral content make it ideal for cleansing, exfoliating, and purifying.

Q: Why choose a China-based 100 calcium bentonite clay manufacturer?

A: China-based manufacturers offer competitive pricing, large-scale production capabilities, and adherence to international quality standards. Many also provide OEM services for customized product solutions.

Q: Do OEM 100 natural calcium bentonite clay factories provide certifications?

A: Reputable OEM factories typically provide certifications like ISO, MSDS, and third-party lab reports. These ensure the clay's purity, safety, and compliance with global regulatory requirements.

Q: How do OEM factories ensure quality in 100 natural calcium bentonite clay?

A: OEM factories implement strict quality control, including raw material testing, batch inspections, and advanced processing techniques. This guarantees consistent particle size, mineral content, and contaminant-free products.

Q: Can OEM 100 natural calcium bentonite clay be customized for specific industries?

A: Yes, OEM factories often tailor clay properties like fineness, additives, or packaging for industries such as cosmetics, agriculture, or construction. Custom formulations meet specific application needs.

Share

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025