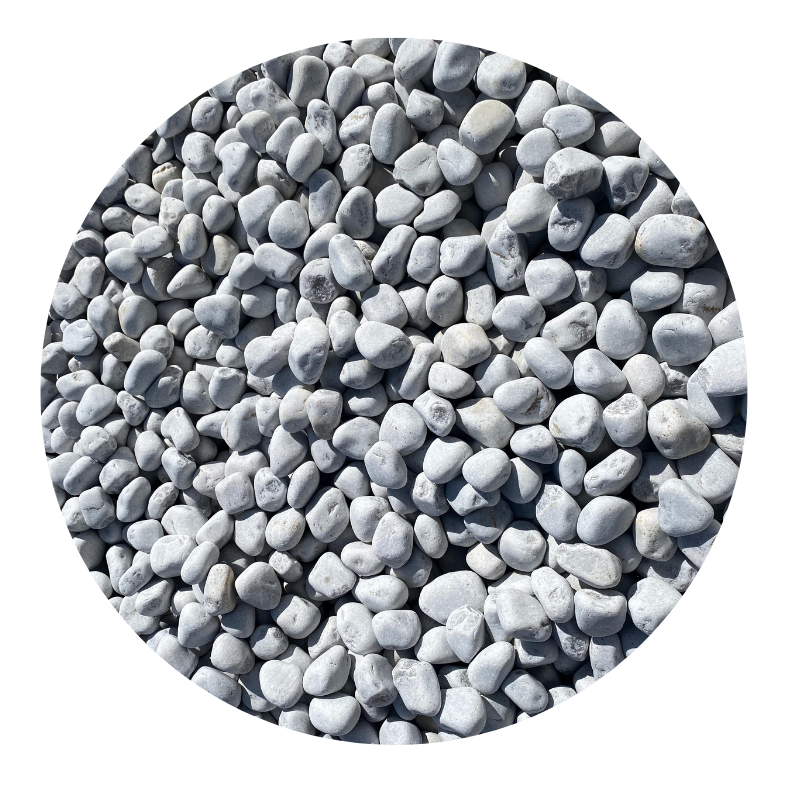

1500 grit silicon carbide powder

The Benefits and Uses of 1500 Grit Silicon Carbide Powder

Silicon carbide (SiC) is a hard, durable material known for its exceptional properties, making it an ideal choice for various industrial applications. Among its many grades, 1500 grit silicon carbide powder is particularly valued for its fine particle size and versatility. This article delves into the characteristics, benefits, and predominant uses of 1500 grit silicon carbide powder, highlighting its significance in different industries.

Understanding Silicon Carbide

Silicon carbide is a compound made of silicon and carbon, boasting outstanding hardness and thermal stability. Unlike traditional abrasives, silicon carbide is a synthetic material, which allows for more precise control over its properties. It has a Mohs hardness rating of 9, just below diamond, making it a popular choice for abrasive applications. Silicon carbide can be produced in various grit sizes ranging from coarse to extremely fine, with 1500 grit representing a very fine particle size ideal for polishing and finishing applications.

Characteristics of 1500 Grit Silicon Carbide Powder

The specific grit size of 1500 indicates that the powder consists of ultra-fine particles, typically around 10 microns in size. This fine grading is crucial for many applications that require a smooth, polished finish. The unique properties of silicon carbide contribute to its effectiveness in these high-precision tasks. It possesses

1. High Hardness Ensuring the powder can withstand significant wear and tear, making it perfect for abrasive applications. 2. Sharp Edges The sharpness of the particles aids in quicker material removal, reducing the time required for grinding and polishing processes. 3. Chemical Stability Silicon carbide is resistant to chemical reactions, making it suitable for use in various environments without degrading. 4. Thermal Conductivity The material disperses heat efficiently, which is essential during processes that generate heat, such as grinding.

Benefits of Using 1500 Grit Silicon Carbide Powder

The utilization of 1500 grit silicon carbide powder offers several advantages across different industries

1. Enhanced Surface Finishing Due to its fine nature, 1500 grit silicon carbide powder is widely used in the final stages of the polishing process. It leaves a smooth and reflective surface on materials such as metals, glass, and ceramics.

2. Versatility This powder can be used on various materials, including hard metals, non-metals, and composite materials. Its adaptability makes it a preferred choice for manufacturers working with diverse substances.

1500 grit silicon carbide powder

3. Improved Efficiency The effectiveness of silicon carbide in removing material quickly reduces processing times, leading to increased productivity in manufacturing environments.

Applications of 1500 Grit Silicon Carbide Powder

The broad range of applications for 1500 grit silicon carbide powder reflects its important role in multiple industries

1. Aerospace and Automotive In these sectors, precise surface finishing is critical for components such as turbines and engine parts, where even minor imperfections can lead to failure.

2. Electronics The electronics industry utilizes silicon carbide powder for polishing glass substrates and semiconductor wafers, ensuring high levels of precision.

3. Ceramics Silicon carbide powder is essential in fabricating ceramic materials, providing the necessary finish and strength.

4. Construction and Masonry It is also used in the preparation of surfaces for tiles and stones, as well as for polishing concrete floors.

5. Jewelry Making Artisans and jewelers use silicon carbide powder to achieve fine finishes on precious metals and stones.

Conclusion

In conclusion, 1500 grit silicon carbide powder is a remarkable abrasive material with numerous benefits across various industries. Its fine grit ensures superior surface finishing, while its hardness and stability make it a reliable choice for demanding applications. As industries continue to seek high-performance materials, the significance of silicon carbide, particularly at 1500 grit, will only grow, solidifying its place as a cornerstone in the world of abrasives and manufacturing processes. Whether used for polishing, grinding, or cutting, this versatile powder showcases the endless possibilities offered by modern material science.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025