Top China OEM Silica Fume for Cement Strength Supplier

- Advantages of silica fume in cement production

- Performance improvement metrics and technical specifications

- OEM manufacturing capabilities for specialized solutions

- Comparative analysis of silica fume manufacturers

- Custom formulation options for different cement grades

- Case studies in major construction projects

- Partner selection criteria for cement factories

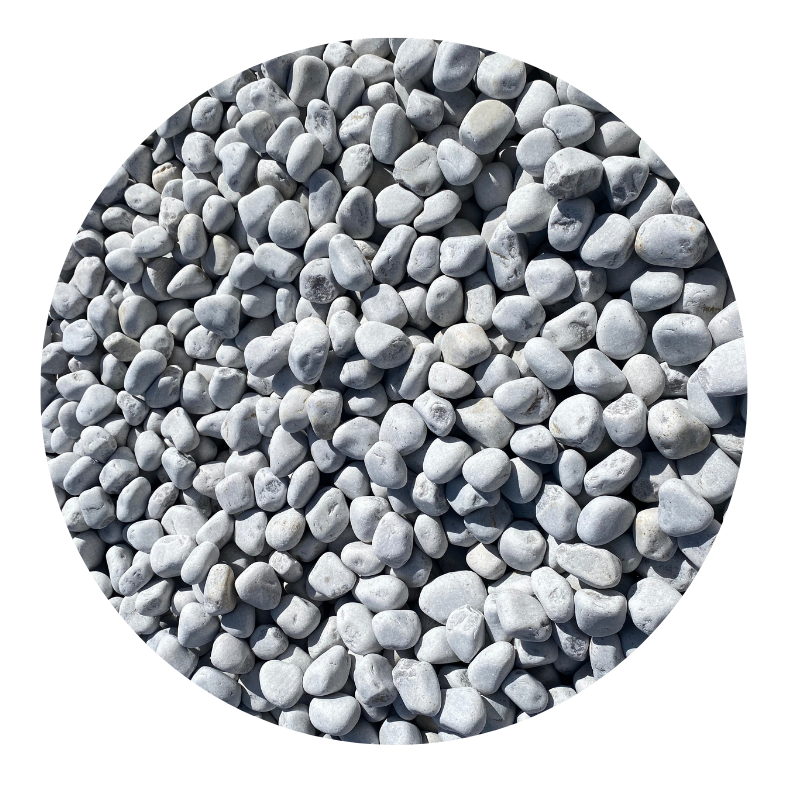

(silica fume for cement)

Why Silica Fume for Cement Delivers Unmatched Performance

Cement production undergoes revolutionary transformation when incorporating silica fume. This microsilica additive modifies the physical structure of concrete at the molecular level, filling voids between cement particles that ordinarily weaken structural integrity. Modern construction demands increasingly rely on silica fume for cement

applications due to its extraordinary binding properties. The substance's ultrafine particle size - averaging just 0.1 microns - creates significantly denser concrete matrices when properly integrated during the mixing phase.

The chemical reaction during curing forms additional calcium silicate hydrate (C-S-H) gel, the primary strength-giving component in concrete. This process boosts compressive strength by 25-35% compared to standard concrete mixes. Chemical resistance improves by up to 8 times against sulfate attacks and chloride penetration, crucial for infrastructure exposed to harsh environments. For bridge decks exposed to deicing salts or marine structures battling seawater corrosion, these technical advantages translate into extended service life exceeding 75+ years. Thermal performance simultaneously improves, with thermal conductivity reduction measuring 15-30% depending on application conditions.

Engineering Breakthroughs: Technical Superiority Explained

Structural engineers increasingly specify silica fume-enhanced concrete for critical applications where failure isn't an option. Laboratory testing reveals water permeability reductions up to 94% compared to conventional concrete, dramatically slowing deterioration processes. The pozzolanic reaction continues months after initial curing, steadily increasing long-term durability without compromising workability when proper water-reducers are implemented. Flexural strength measurements show 20-30% improvements while abrasion resistance increases 35-40%, crucial for industrial flooring and pavement applications.

Beyond basic strength parameters, silica fume modifies the cement paste-to-aggregate interface, eliminating the weak transition zone responsible for most micro-cracking. This interface enhancement allows structures to withstand higher cyclical loading without structural fatigue. High-performance concretes exceeding 100 MPa compressive strength become commercially viable without exotic materials through precise silica fume integration. When engineered into self-consolidating concrete (SCC) mixes, the technology maintains homogeneity during pouring while eliminating vibration requirements.

Manufacturing Metrics: Quantitative Performance Data

Industry-standard testing consistently demonstrates silica fume's impact on cement quality:

| Performance Metric | Control Sample | 10% Silica Fume | Improvement |

|---|---|---|---|

| Compressive Strength (28-day) | 42 MPa | 56 MPa | +33% |

| Chloride Ion Permeability | 3,200 Coulombs | 580 Coulombs | -82% |

| Water Absorption | 5.8% | 2.1% | -64% |

| Abrasion Resistance | 0.72 mm loss | 0.41 mm loss | -43% |

| Sulfate Resistance Expansion | 0.12% | 0.04% | -67% |

The tabulated data underscores why architects increasingly specify minimum silica fume content ranging from 7-12% in structural applications. Performance thresholds once requiring expensive specialty cements become achievable through precision enhancement rather than wholesale material substitution.

Leading Silica Fume Production Capabilities

Global cement manufacturers partner with specialized producers offering distinct technical capabilities. Premium suppliers operate submerged electric arc furnaces specifically engineered for microsilica production rather than recycling by-products from other industrial processes. This direct manufacturing approach ensures consistent particle size distribution averaging 94% < 45μm and carbon content maintained below 1.5%. Production facility certification against ISO 9001:2015 quality standards distinguishes high-caliber operators.

Forward-thinking manufacturers implement automated production monitoring systems that track temperature gradients, chemical composition, and particle morphology during furnace operations. Sophisticated electrostatic collection technology captures fume particles without contamination before packaging in moisture-proof containers. Production volumes now range from 10,000 to over 150,000 metric tons annually, with manufacturing footprints optimized for global logistics to cement producers across continents.

Customized Silica Fume Formulation Options

Specialized concrete applications demand specific silica fume characteristics requiring bespoke OEM manufacturing. Producers with advanced technical capabilities offer multiple formulations:

Undensified Microsilica: Preserves original particle structure maximizing reactivity and flow characteristics, ideal for fiber-reinforced applications.

Densified Microsilica: Compressed pellets optimize bulk density reaching 600 kg/m³ for transport efficiency while maintaining chemical properties.

Slurry Formulations: Premixed aqueous suspension simplifies batch plant integration with guaranteed dispersion throughout the mixture.

Surface-Modified Variants: Chemically treated particles designed to enhance compatibility with specific plasticizer formulations.

Leading manufacturers tailor composition parameters including silicon dioxide concentration (typically 85-99%), alkali content (<1.5%), and loss on ignition (<3%). Production agreements include proprietary blending sequences that optimize rheology parameters for specialized applications such as underwater concreting or rapid-strength development formulations.

Demonstrated Performance in Global Infrastructure

Major engineering projects validate silica fume's practical benefits. Norway's North Sea oil platforms implemented silica fume concrete achieving 125-year design life despite aggressive marine exposure conditions. Tunnel boring operations beneath London achieved breakthrough accuracy requiring concrete with exactly specified rheological properties only achievable through specialized microsilica formulations. Data centers requiring thermal mass without structural bulk utilize high-performance silica fume mixtures to optimize material efficiency.

Accelerated bridge construction projects throughout North America demonstrate how specialized silica fume mixtures deliver high-early-strength requirements. Concrete reaches 35 MPa within 18 hours while simultaneously achieving low permeability measurements under 1000 coulombs. These technical achievements validate advanced specification requirements increasingly becoming standard in infrastructure procurement globally.

Selecting Reliable China Silica Fume in Cement Manufacturers

Cement factories seeking OEM silica fume for cement factories require certified technical partners. Reputable manufacturers document complete product traceability from furnace to packaging with batch-specific lab analysis certificates covering twelve critical parameters. Production facilities operate under audited quality systems featuring continuous process control instrumentation. Logistics infrastructure guarantees chemical stability during transit including climate-controlled storage and specialized transport packaging.

Technical partnerships with leading material scientists enable customization beyond standard formulations. Joint material development programs create application-specific solutions addressing unique climate challenges, sustainability mandates, or specific structural requirements. Reliable China silica fume manufacturers provide comprehensive material safety data documentation validated by independent laboratories. Production schedules coordinate seamlessly with cement factory requirements including just-in-time delivery protocols ensuring uninterrupted production flow.

Quality verification begins with transparent inspection protocols that include sample comparisons against reference materials maintained by international standards organizations. Manufacturing investment ensures constant innovation with advanced production technology upgrades implemented every 36-48 months. Material performance warranties cover consistency of chemical composition and particle size distribution specifications critical for predictable engineering outcomes in cement production.

(silica fume for cement)

FAQS on silica fume for cement

以下是围绕指定关键词创建的5组英文FAQ问答(HTML富文本格式):Q: What is silica fume in cement applications?

A: Silica fume enhances cement strength and durability as a supplementary cementitious material. It fills voids between cement particles due to its ultra-fine particle size. This significantly improves concrete density and reduces permeability in structures.

Q: Why choose Chinese silica fume manufacturers for cement?

A: China dominates global silica fume production with cost-effective solutions meeting international standards. Top manufacturers offer engineered products specifically optimized for cement and concrete applications. They provide rigorous quality control and bulk supply capabilities for construction projects.

Q: Can OEM silica fume be customized for cement factories?

A: Yes, OEM factories provide tailored silica fume formulations for specific cement applications. They adjust particle size distribution and chemical composition to meet factory requirements. Custom packaging with bulk delivery options is also available for production facilities.

Q: How does silica fume improve high-performance cement?

A: Silica fume reacts with calcium hydroxide to form additional calcium-silicate-hydrate (CSH). This enhances compressive strength by 20-35% and reduces bleeding/segregation. Its fine particles also increase abrasion resistance and protect reinforcement steel from corrosion.

Q: What certifications should OEM silica fume factories have?

A: Reputable manufacturers hold ISO 9001 quality management certification and EN 13263 silica fume standards compliance. They should provide material test reports confirming ASTM C1240 or equivalent specifications. Environmentally conscious producers also maintain ISO 14001 environmental certifications.

Share

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025