Applications and Benefits of Glass Bead Blasting in Surface Preparation Processes

The Art and Science of Glass Beads Blasting

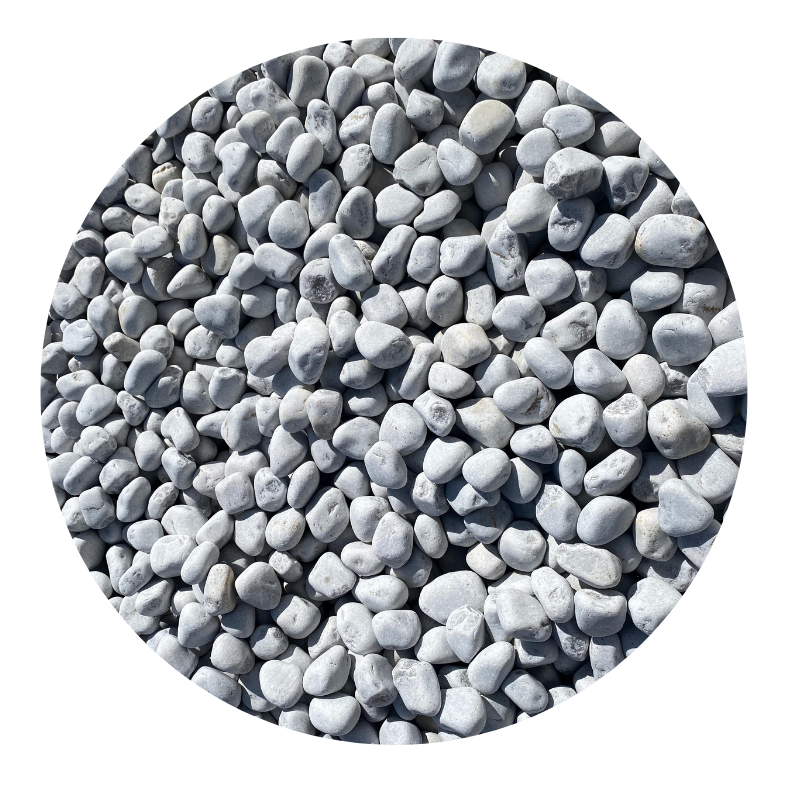

Glass beads blasting is a unique technique employed in various industries for surface finishing, cleaning, and preparation. This method utilizes small, spherical glass beads that are propelled at high velocities against hard surfaces. Through this process, a range of benefits can be achieved, making it a favored choice in applications from automotive to aerospace, and even artistic endeavors.

What is Glass Beads Blasting?

At its core, glass beads blasting is a form of abrasive blasting, where abrasive materials are used to smooth, polish, or clean a surface. The glass beads themselves, typically made from high-quality soda-lime glass, are manufactured in various sizes depending on the application's requirements. When these beads are propelled using compressed air or other methods, they create a gentle yet effective impact against the workpiece.

The key feature of glass beads is their uniform size and shape, which allows for a consistent finish without causing significant damage to the substrate. Unlike harsher abrasives, glass beads create a peening effect, where the surface is slightly compressed, enhancing durability while avoiding deep pitting or surface imperfections.

Applications of Glass Beads Blasting

1. Surface Preparation One of the primary applications of glass beads blasting is preparing surfaces for painting, coating, or further processing. This is particularly important in industries where surface integrity influences product performance. By removing contaminants and oxidation, glass beads blasting ensures that coatings adhere properly, reducing the risk of peeling or blistering.

2. Cleaning In industries like aerospace and automotive, components often require thorough cleaning to meet strict quality standards. Glass beads are effective at removing dirt, grease, and other stubborn residues without damaging delicate components. This makes them ideal for cleaning intricate parts such as engine components and turbine blades.

3. Finishing For manufacturers seeking a polished appearance, glass beads blasting can achieve a uniform and attractive surface finish. This is common in decorative applications, where products like jewelry, glass surfaces, and architectural elements are treated with glass beads to achieve a sleek and refined look.

4. Metal Hardening The peening effect produced by glass beads blasting can enhance the fatigue strength of metals. This is particularly useful in applications where components experience repeated stress. By compressing the surface material, the technique can extend the lifespan of parts subjected to heavy loads.

glass beads blasting

Advantages of Glass Beads Blasting

The benefits of glass beads blasting extend beyond just the immediate results. Some key advantages include

- Non-Toxic and Inert Being made of non-toxic materials, glass beads are environmentally friendly and pose minimal health risks to operators. This is important in today’s world, where safety and environmental considerations are paramount.

- Versatility Glass beads can be used on various materials, including metals, plastics, and glass itself. This versatility makes them a one-stop solution for many applications across different industries.

- Less Aggressive than Other Abrasives Compared to harder materials like steel grit or aluminum oxide, glass beads provide a less aggressive option for surface treatment. This minimizes the risk of surface damage, making it ideal for delicate finishes or components.

Considerations When Using Glass Beads Blasting

While glass beads blasting offers numerous advantages, there are factors to consider. For instance, the size and weight of the beads may affect the blasting speed and finish quality. Moreover, the equipment used must be adequately calibrated to ensure optimal results while minimizing waste.

Finally, after the blasting process, it is crucial to undertake proper cleaning of the surface to remove any residual beads and contaminants to ensure the highest quality finish.

Conclusion

In summary, glass beads blasting is an essential process in modern industrial applications. By leveraging the unique properties of glass beads, manufacturers can achieve high-quality finishes, superior cleaning, and effective surface preparation. Its versatility, coupled with environmental safety, makes glass beads blasting a valuable technique across multiple sectors, showcasing the balance of art and science in industrial processes. Whether through enhancing durability or perfecting aesthetics, glass beads blasting continues to play a pivotal role in materials processing and surface engineering.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025