Custom Fly Ash Innovations for Enhanced Performance in Concrete Mixes

The Role of Custom Fly Ash in Concrete Innovations and Benefits

Concrete is one of the most widely used construction materials in the world, playing a crucial role in infrastructure development, buildings, and various constructions. Among the various components that enhance the properties of concrete, fly ash is gaining significant attention. Fly ash, a byproduct of coal combustion in power plants, is increasingly being used to create a more sustainable and durable concrete mix, and its customization is paving the way for innovative construction practices.

Understanding Fly Ash

Fly ash comes in two primary types Class F and Class C. Class F fly ash is produced from burning anthracite and bituminous coal, while Class C fly ash comes from lignite coal. The key characteristics that make fly ash an excellent addition to concrete are its pozzolanic properties. When combined with lime (calcium hydroxide), fly ash reacts chemically to form compounds possessing cementitious properties. This leads to-enhanced strength, durability, and workability of concrete.

Customization of Fly Ash

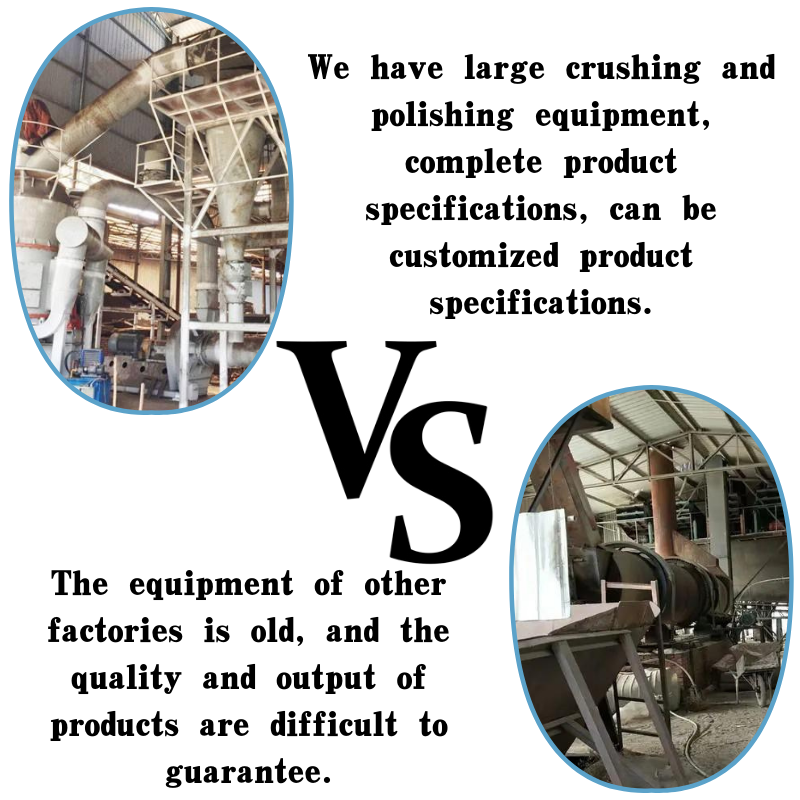

Custom fly ash refers to the tailored processing of fly ash to meet specific requirements for various concrete applications. This customization involves adjusting factors such as fineness, specific gravity, and chemical composition, allowing for the production of fly ash that meets stringent project specifications. The use of specially formulated fly ash can help achieve desired performance characteristics in concrete, making it suitable for a wide range of applications, from residential buildings to large-scale infrastructure projects.

Benefits of Using Custom Fly Ash in Concrete

custom fly ash in concrete

1. Sustainability The incorporation of custom fly ash in concrete plays a significant role in sustainable construction. By utilizing a byproduct of coal combustion, the need for traditional cement is reduced, which in turn lowers carbon emissions and the environmental footprint associated with cement production. Custom fly ash can replace a portion of the Portland cement in concrete mixes, making them more environmentally friendly.

2. Enhanced Workability Custom fly ash can improve the workability of concrete. It is known to enhance the fluidity of fresh concrete, allowing for easier placement and better compaction. Improved workability is particularly beneficial in complex forms and congested reinforcement areas, where traditional concrete mixes may struggle.

3. Increased Durability Concrete containing custom fly ash exhibits greater durability over time, making it an ideal choice for projects subjected to harsh conditions, such as abrasion, chemical exposure, or freeze-thaw cycles. The pozzolanic activity of fly ash leads to a denser microstructure, reducing permeability and enhancing resistance to destructive agents.

4. Cost-Effectiveness Custom fly ash is often more cost-effective than traditional cement. By substituting cement with fly ash, construction projects can achieve significant savings in material costs. Additionally, the energy savings associated with producing concrete with lower cement content can contribute to overall project budgeting.

5. Optimized Performance The ability to customize fly ash allows engineers and architects to fine-tune the properties of concrete to meet specific performance criteria. This optimization can address challenges such as high early strength requirements, low heat of hydration, or specific aesthetic preferences.

Conclusion

The increasing adoption of custom fly ash in concrete represents a meaningful shift towards sustainability and performance in the construction industry. As more project managers, engineers, and architects recognize the benefits of integrating this innovative material into their designs, we can expect to see its continued growth in popularity. The future of concrete construction may very well depend on how effectively we utilize byproducts like fly ash, turning waste into valuable resources that contribute to eco-friendly and durable infrastructures. Through customization, fly ash is not just a supplementary material; it is becoming an essential component of modern concrete solutions.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025