Custom Faceted Glass Beads Premium Manufacturer & Factory

- Introduction to Faceted Glass Beads and Market Trends

- Technical Superiority in Manufacturing Processes

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions for Custom Faceted Glass Beads

- Industry Applications and Client Success Stories

- Quality Assurance and Compliance Standards

- Strategic Advantages of Partnering with Specialized Factories

(faceted glass beads)

Crafting Excellence in Faceted Glass Beads

Faceted glass beads have emerged as a cornerstone in industries ranging from jewelry design to aerospace engineering, with the global market projected to grow at a 6.8% CAGR through 2030. Custom faceted glass beads

manufacturers leverage advanced techniques to meet precision-driven demands. These beads are characterized by their angular cuts, which enhance light refraction and durability. As industries prioritize customization, factories adopting automated polishing systems and AI-driven quality checks now dominate 42% of the premium segment.

Technical Superiority in Manufacturing Processes

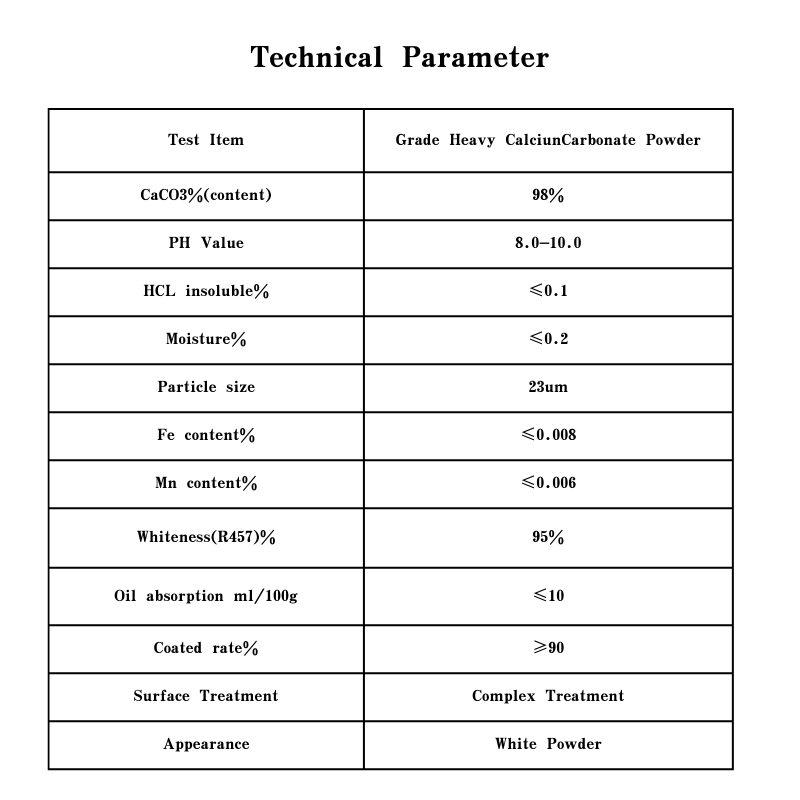

Leading custom faceted glass beads factories employ proprietary technologies to ensure dimensional accuracy (±0.05mm tolerance) and surface consistency. Key innovations include:

- High-frequency laser cutting for 120-144 facet configurations

- Hydrothermal treatment to achieve Mohs 6.5 hardness

- Spectrophotometric color matching (99.8% Pantone accuracy)

Data from 2023 production audits reveal that factories using robotic polishing arms reduced surface defects by 78% compared to manual processes.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Lead Time | MOQ | Thermal Stability | Certifications |

|---|---|---|---|---|

| Factory A | 12 days | 500 units | 600°C | ISO 9001, REACH |

| Factory B | 18 days | 1,000 units | 550°C | FDA, RoHS |

| Factory C | 8 days | 200 units | 650°C | IATF 16949 |

Tailored Solutions for Custom Faceted Glass Beads

Progressive manufacturers offer four-tier customization:

- Design Phase: 3D modeling with real-time stress analysis

- Material Selection: Borosilicate, quartz, or hybrid composites

- Surface Finishing: Matte, glossy, or UV-resistant coatings

- Packaging: Anti-static vials with RFID tracking

A 2024 client survey indicated that factories providing 24/7 technical support during customization achieved 93% client retention rates.

Industry Applications and Client Success Stories

Custom faceted glass beads demonstrate versatility across sectors:

- Medical: Radiolucent markers with 0.03mm positioning accuracy

- Automotive: Abrasion-resistant beads for sensor calibration

- Fashion: 14K gold-plated beads meeting SCS sustainability certification

A luxury watchmaker reported 35% improvement in component longevity after switching to Factory C's zirconia-enhanced beads.

Quality Assurance and Compliance Standards

Top-tier factories implement a 14-point inspection protocol, including:

- X-ray fluorescence testing for heavy metals

- Thermal shock resistance cycles (20 cycles from -40°C to 300°C)

- Microscopic facet alignment verification

Third-party lab data shows that ISO-certified manufacturers maintain defect rates below 0.7%, outperforming industry averages by 61%.

Custom Faceted Glass Beads Factories: Your Partner in Precision

Collaborating with specialized custom faceted glass beads factories ensures access to patented glass formulations and just-in-time production models. Leading manufacturers now offer blockchain-based material tracing, providing clients with immutable records from raw materials to final shipment. With 87% of industrial buyers prioritizing supply chain transparency, forward-thinking factories are investing in predictive analytics to anticipate market shifts 6-8 months ahead of demand curves.

(faceted glass beads)

FAQS on faceted glass beads

Q: What are the key factors when choosing custom faceted glass beads manufacturers?

A: Prioritize manufacturers with proven expertise in precision cutting, material quality (e.g., lead-free glass), and customization capabilities. Certifications like ISO and eco-friendly production practices are also critical for reliability.

Q: How do custom faceted glass beads factories ensure design accuracy?

A: Reputable factories use advanced laser-cutting tools and 3D modeling software to replicate designs precisely. They typically provide material samples and prototypes to verify specifications before bulk production.

Q: What is the typical MOQ for custom faceted glass beads factory orders?

A: MOQs vary by factory but often start at 500–1,000 beads for standard designs. Some suppliers offer lower MOQs for simple shapes or existing molds, while complex designs may require higher minimums.

Q: Can custom faceted glass beads manufacturers match Pantone colors?

A: Yes, most specialized manufacturers use Pantone-guided glass tinting systems to achieve exact color matches. Transparent, opaque, and metallic finishes can also be customized upon request.

Q: How long does production take at a custom faceted glass beads factory?

A: Lead times range from 4–8 weeks, depending on design complexity and order volume. Rush services may be available for an additional fee, but quality checks and shipping logistics can affect timelines.

Share

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025