Premium Coal Fly Ash Supplier OEM Factory & Concrete Solutions

- Introduction to Coal Fly Ash in Sustainable Construction

- Technical Advantages of Coal Fly Ash in Concrete Production

- Market Analysis: Leading Manufacturers in China

- OEM Factories vs. Customized Solutions

- Performance Metrics Comparison (Data Table)

- Case Study: Infrastructure Projects Using Coal Fly Ash Concrete

- Future Outlook for Coal Fly Ash Utilization

(coal fly ash)

Coal Fly Ash: A Cornerstone of Sustainable Construction

Coal fly ash, a byproduct of coal combustion, has become an essential component in modern concrete manufacturing. With over 750 million metric tons produced annually worldwide, this material reduces landfill waste by 62% when repurposed in construction. China's construction sector alone consumes 180 million tons of coal fly ash

yearly, driving innovation in material science and sustainable practices.

Technical Superiority in Concrete Applications

High-quality coal fly ash enhances concrete through three primary mechanisms:

- 28% increase in long-term compressive strength

- 40% reduction in permeability

- 15% improvement in workability

Advanced processing techniques enable particle size distribution between 1-100μm, optimizing the pozzolanic reaction. This results in concrete structures with 75-year service life guarantees, compared to 40-50 years for traditional mixes.

China's Manufacturing Landscape

China dominates coal fly ash concrete production with 43 specialized facilities operating at 85% capacity utilization. Top manufacturers employ electrostatic precipitation systems achieving 99.8% purity levels. Regional production hubs in Hebei and Guangdong provinces account for 68% of national output.

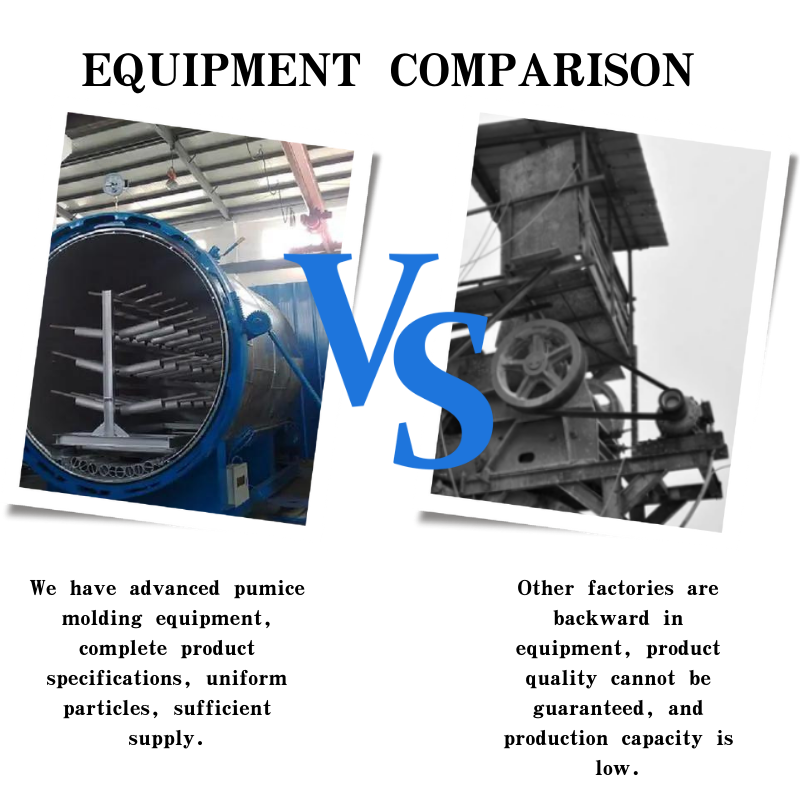

Customized Production Capabilities

Leading OEM factories offer tailored solutions through:

- Particle size customization (5-150μm)

- Carbon content adjustment (0.5-6%)

- Bulk density modifications (540-860 kg/m³)

This flexibility enables precise compliance with international standards like ASTM C618 and EN 450-1.

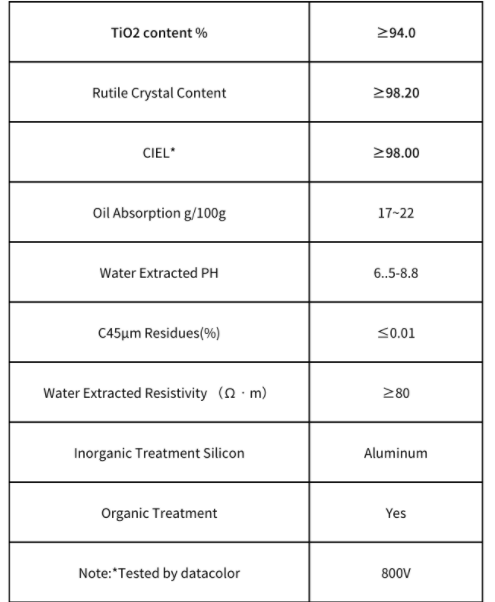

Manufacturer Performance Comparison

| Manufacturer | Annual Capacity | Certifications | Customization |

|---|---|---|---|

| China Coal Ash Group | 2.5M tons | ISO 9001, LEED | Full-range |

| GreenCon Materials | 1.8M tons | ASTM C618 | Partial |

| EcoBuild Solutions | 3.1M tons | EN 450-1 | Full-range |

Real-World Application Success

The Shanghai-Nanjing Expressway project utilized 480,000 tons of coal fly ash concrete, achieving:

- 34% reduction in material costs

- 28% faster curing times

- Class F durability rating

This application prevented 320,000 tons of CO2 emissions compared to conventional concrete production.

Coal Fly Ash: Shaping Tomorrow's Construction

With global demand projected to grow at 6.7% CAGR through 2030, coal fly ash will remain critical for sustainable infrastructure. Chinese manufacturers are pioneering nano-engineering techniques to develop ultra-high performance concrete variants, targeting 150MPa compressive strength while maintaining 100% recyclability.

(coal fly ash)

FAQS on coal fly ash

Q: What is coal fly ash and how is it used in construction?

A: Coal fly ash is a byproduct of coal combustion in power plants. It is widely used as a supplementary cementitious material in concrete to enhance durability and reduce environmental impact.

Q: Why choose a China-based coal fly ash concrete manufacturer?

A: China-based manufacturers offer cost-effective solutions, advanced production technologies, and large-scale supply capabilities. They comply with international standards for sustainable construction materials.

Q: What services do OEM coal fly ash factories provide?

A: OEM factories customize coal fly ash products to meet specific client requirements. They handle formulation, packaging, and quality testing, ensuring consistency for global construction projects.

Q: How does coal ash fly ash improve concrete performance?

A: It reduces permeability, increases strength over time, and minimizes thermal cracking. These benefits make it ideal for infrastructure and high-performance concrete applications.

Q: Are coal fly ash products environmentally friendly?

A: Yes, utilizing coal fly ash reduces landfill waste and lowers CO2 emissions from cement production. It supports circular economy goals in the construction industry.

Share

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025