micro glass beads manufacturer

The Innovative World of Micro Glass Beads Manufacturing

In recent years, the demand for micro glass beads has surged across various industries due to their unique properties and versatile applications. Micro glass beads are tiny glass spheres typically ranging from 1 to 100 micrometers in diameter. These beads are manufactured through a precise and innovative process, ensuring that they meet the high standards required for different applications such as reflective materials, cosmetics, and industrial products.

Manufacturing Process of Micro Glass Beads

The manufacturing of micro glass beads involves several critical steps. Firstly, high-quality raw materials, primarily silica sand, are sourced and processed. The purity of the raw materials is essential because impurities can affect the properties of the final product. Upon preparation, the materials are melted at high temperatures in a furnace, where they transition into a molten glass state.

The molten glass is then processed through various methods to create micro beads. One common technique is the spray drying process, where the molten glass is atomized into fine droplets. As these droplets cool, they solidify into spherical shapes. Another method involves the use of special nozzles that produce a fine mist of glass, which then undergoes rapid cooling to form beads.

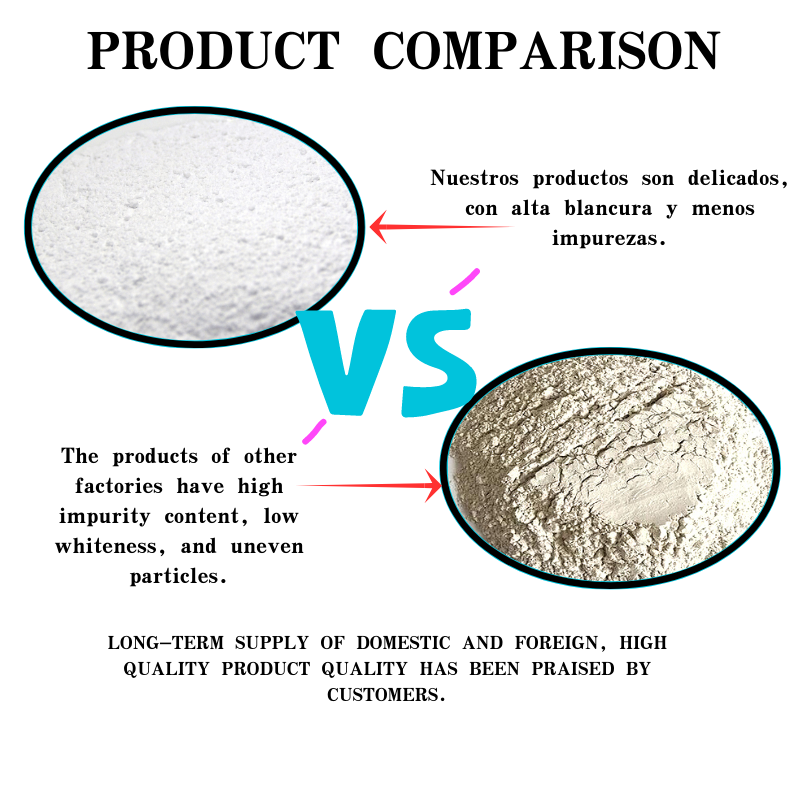

Quality control is a critical aspect of micro glass bead production. Manufacturers conduct thorough inspections throughout the process, utilizing advanced technologies such as laser particle size analyzers to ensure that the beads meet the desired specifications regarding size, roundness, and opacity. The end products are typically sorted and classified based on their measurements, ensuring consistency and quality for the end-user.

Applications of Micro Glass Beads

The versatility of micro glass beads allows them to be utilized in a myriad of applications. One of the most prominent uses is in the production of reflective materials. When incorporated into paints and coatings, micro glass beads enhance visibility by reflecting light, making them invaluable for road safety signs, traffic markings, and safety clothing. This retro-reflective ability significantly increases visibility, particularly in low-light conditions, ultimately contributing to improved safety standards in transportation systems.

micro glass beads manufacturer

In the cosmetics industry, micro glass beads are employed as a key ingredient in various beauty products. Their smooth texture allows for gentle exfoliation, making them ideal for facial scrubs and body exfoliants. Additionally, they can serve as carriers for active ingredients, enhancing the efficacy of skincare products. The unique aesthetic properties of these beads also make them popular in nail polish and makeup formulations, contributing to a shimmering effect that enhances the overall appearance of cosmetic products.

Furthermore, micro glass beads find application in industrial settings. They are often used as additives in cement and concrete, improving strength and durability. Their reflective properties can also enhance the safety features of surfaces by integrating them into asphalt and pavement materials. The incorporation of micro glass beads helps to minimize glare and improve visibility during nighttime, making them a practical choice for road construction.

Sustainability and Future Trends

As industries continue to evolve, manufacturers of micro glass beads are also exploring sustainable practices. The glass recycling industry has gained momentum, and some manufacturers are incorporating recycled glass into their production processes. By using post-consumer glass waste, the environmental impact of manufacturing can be significantly reduced, aligning with the global push towards sustainability.

In addition to sustainability, advancements in technology are paving the way for the future of micro glass bead manufacturing. Innovations involving automated processes and enhanced precision ensure higher production rates and improved product quality. The integration of smart technologies and data analytics can further optimize production efficiency while reducing waste.

Conclusion

The world of micro glass beads manufacturing is a testament to innovation and adaptability in response to changing market demands. With applications ranging from road safety to cosmetic enhancements, these tiny beads are making a significant impact across various sectors. As we move forward, the industry is likely to embrace more sustainable practices and technological advancements, ensuring that micro glass beads will remain pivotal in driving future innovations. Through these developments, manufacturers will continue to provide high-quality products that meet the evolving needs of consumers and industries alike.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025